Bolt-restrained detachable buckling-resistant brace members

An anti-buckling bracing and bolt technology, applied in building components, anti-vibration and other directions, can solve the problems of difficult production limit, excessive consumption of unbonded materials, waste of materials, etc., to avoid overall or local instability, and to achieve strong operability. , improve the effect of constraint performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

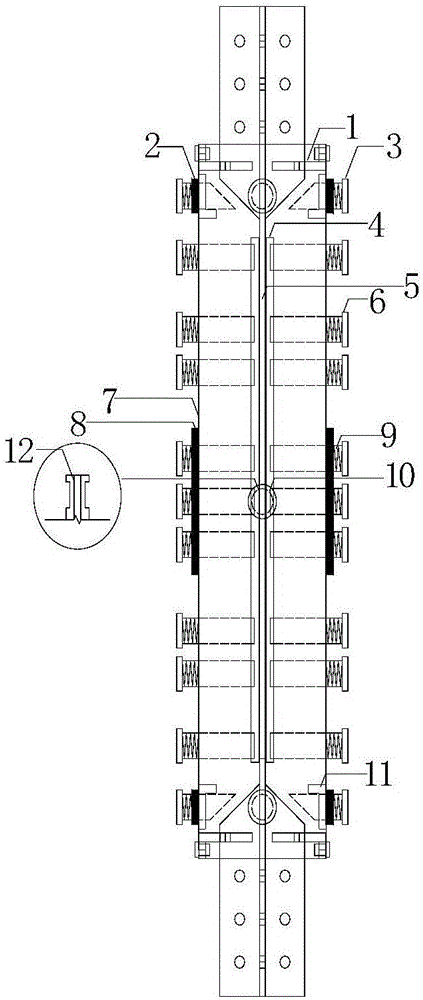

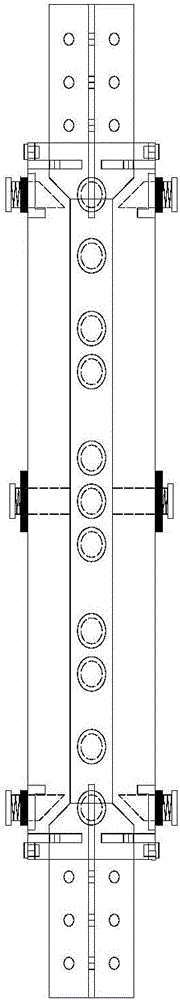

[0038] The accompanying drawings disclose non-restrictive structural schematic diagrams of preferred embodiments involved in the present invention, and the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

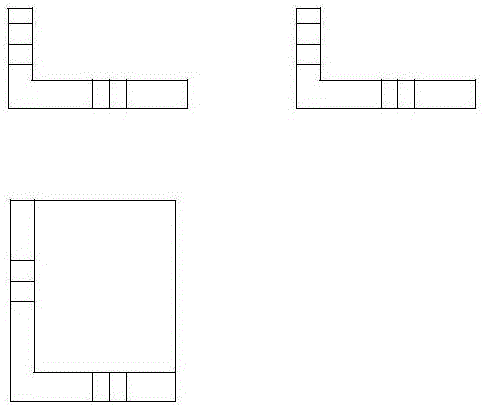

[0039] Such as figure 1 , figure 2 For the schematic diagram of bolt-constrained detachable buckling-resistant brace, first determine the core element required by the design, and determine the type and size of the core element 5 of the member. The number and size of the constraining bolts 6 are determined by the size and type of the core unit of the component, the size of the square steel pipe 7 is determined by the length of the core unit and the number of bolt sizes, and the positioning constraint bolt holes and limit bolt holes are designed on the peripheral square steel pipe.

[0040] The detachable anti-buckling support member constrained by bolts includes an outer restraint unit and a core unit. The cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com