Transmission And Clutch Assembly For Transmission

A technology of clutch components and transmissions, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve problems such as poor application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

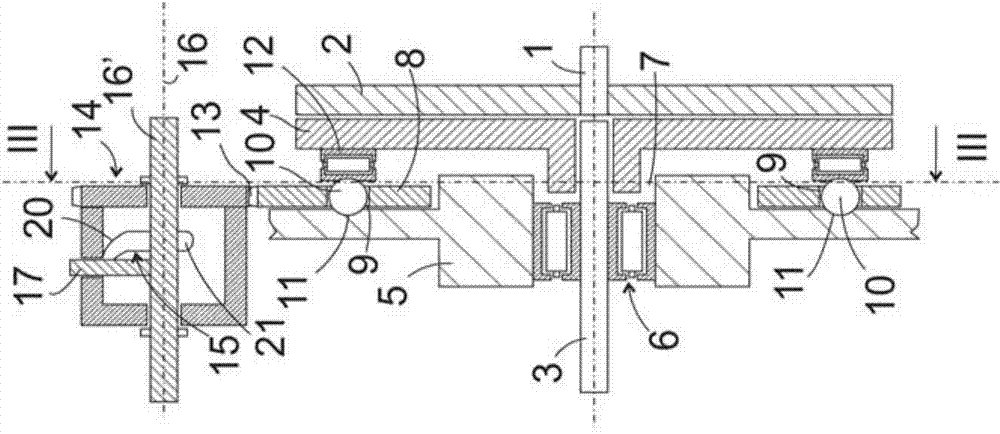

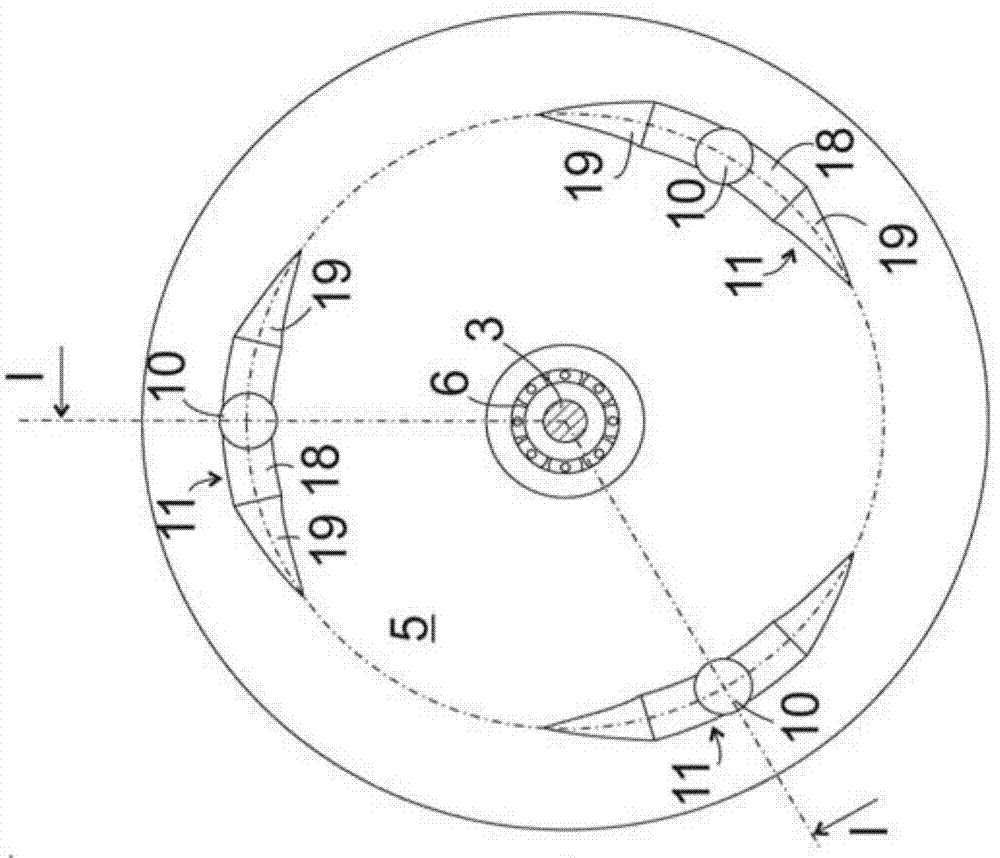

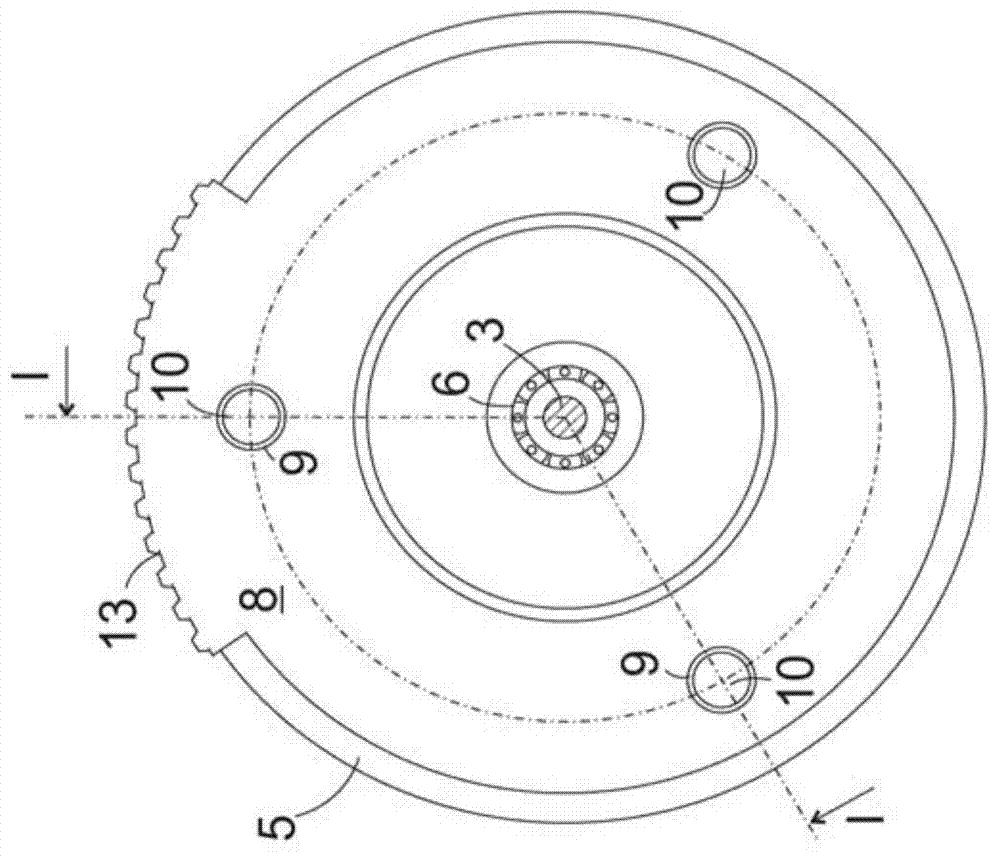

[0027] figure 1 The clutch pack according to the first embodiment of the invention is shown in a simplified diagram. A first clutch disk 2 is mounted on the first shaft 1 in a rotationally fixed and axially immovable manner. A second shaft 3 is arranged coaxially opposite the end of the shaft 1 . The second shaft 3 supports the second clutch disk 4 in a rotationally fixed but axially displaceable manner. The shaft 3 extends through the bore of a plate-shaped bracket 5 which is fixedly connected to the housing of the clutch (not shown) or forms a wall of the housing. The shaft 3 is held and guided in the opening 7 of the carrier 5 by means of a rolling bearing 6 .

[0028] Extending coaxially to the shaft 1 , a disk-shaped holder 8 with a plurality of axial bores 9 extends annularly around the opening 7 and holds an adjusting body 10 in each case. The adjusting body 10 is here in the shape of a ball; other shapes, such as cylindrical or frusto-conical, are likewise conceiva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com