Noodle basket used for cooking noodles

A noodle basket and noodle cooking technology, applied in the direction of plug-in, can solve the problems of increasing the manufacturing cost of the machine, affecting the working environment, occupying the space of the workbench, etc., and achieving the effect of reducing the production cost of the machine, simplifying the mechanism of the machine, and being convenient and quick to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

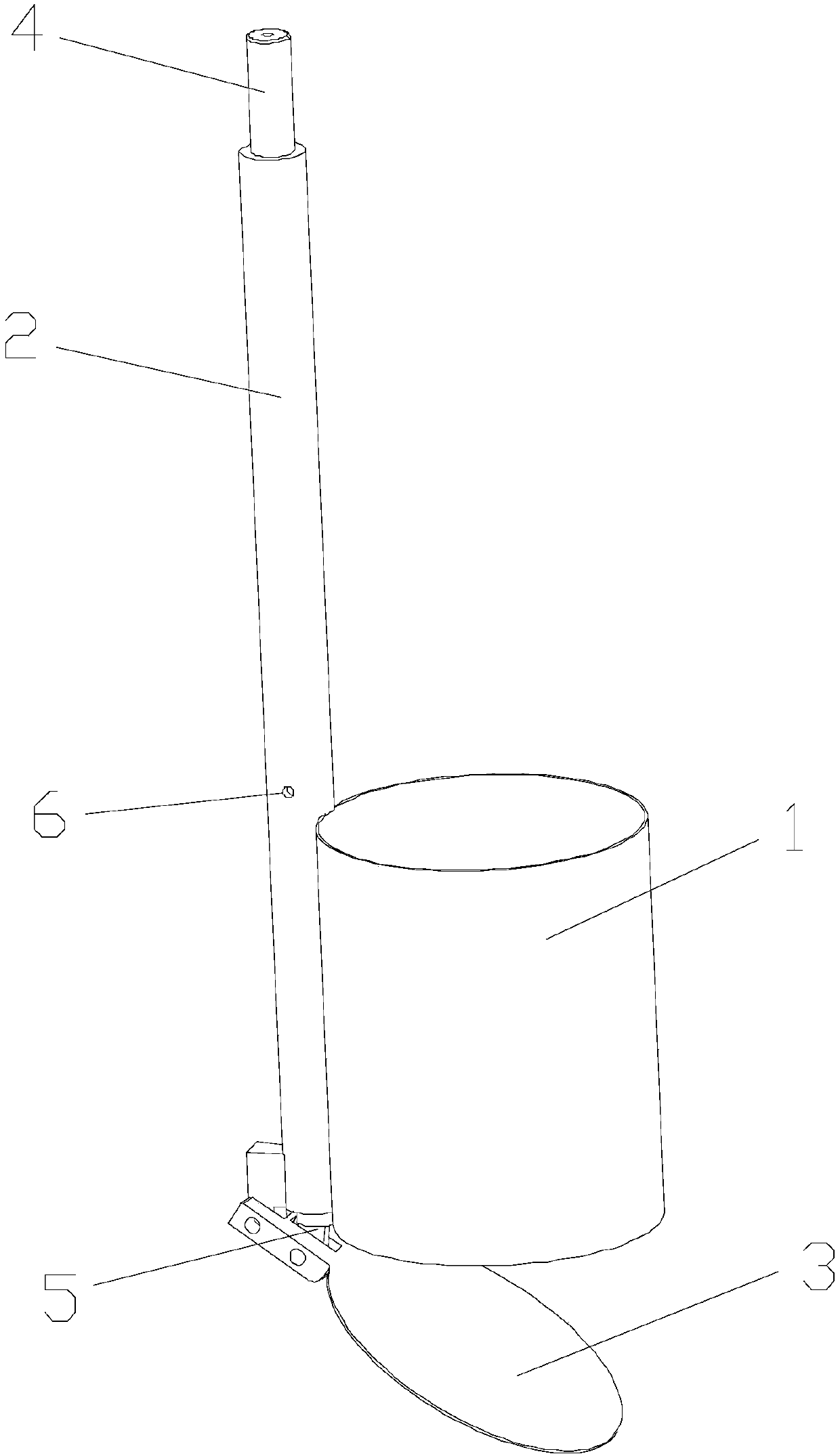

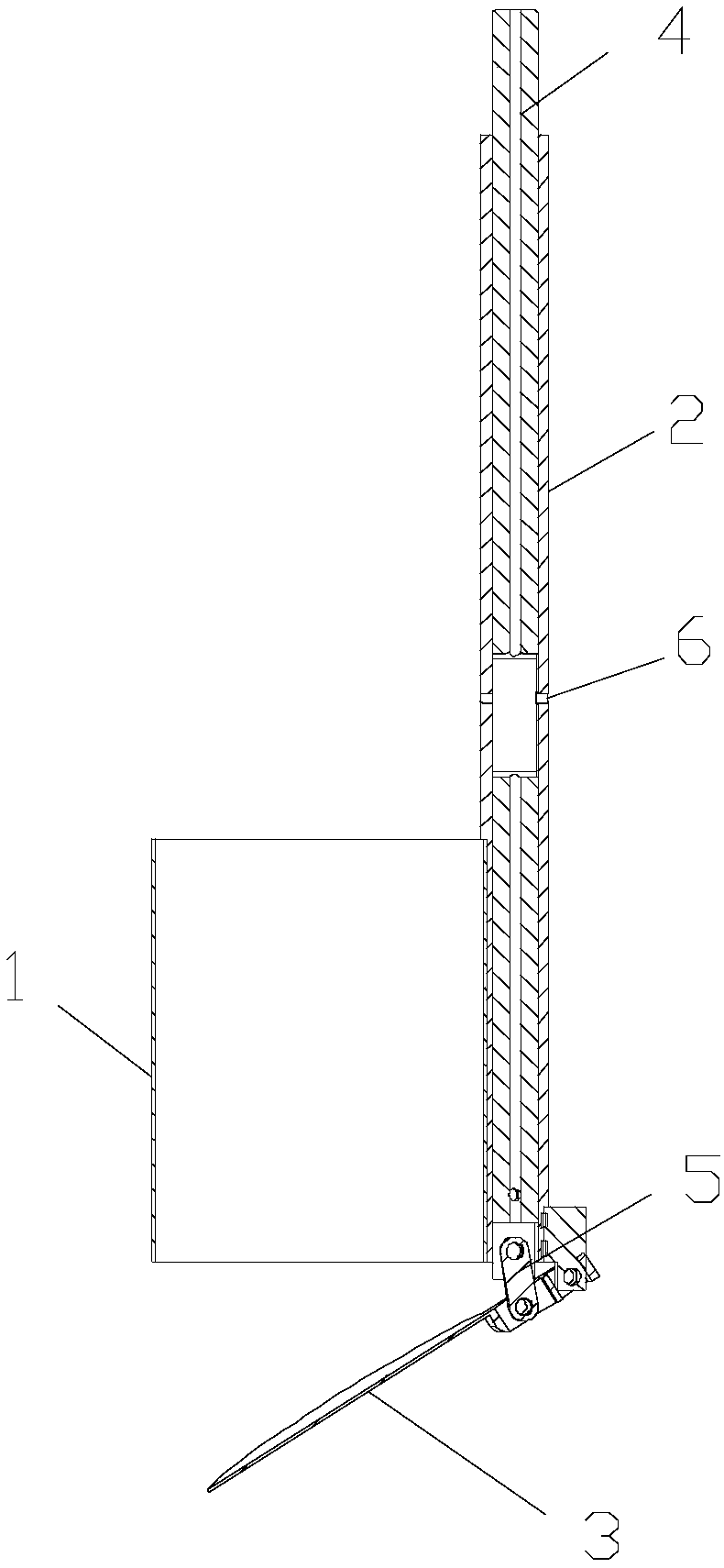

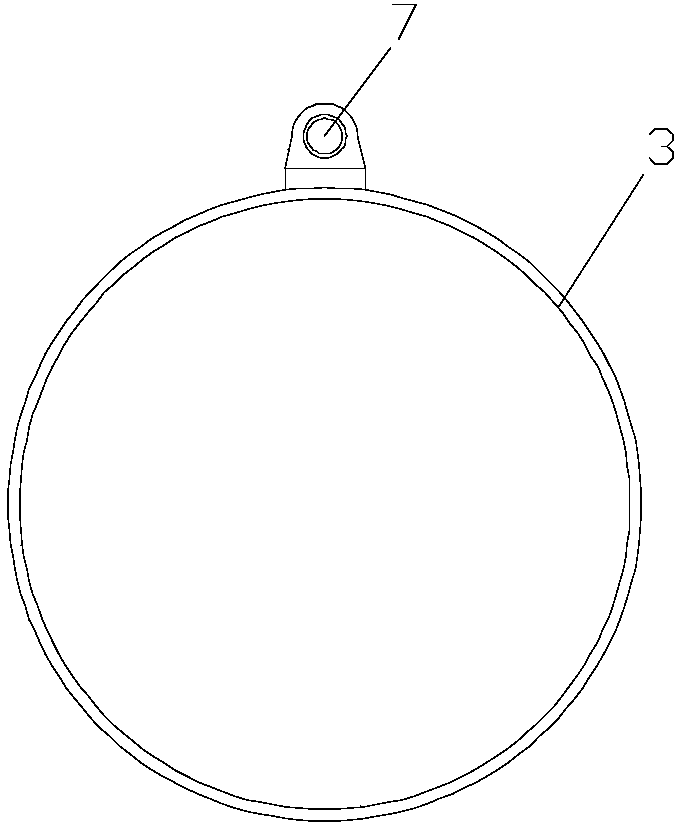

[0016] refer to Figure 1 to Figure 3 , a noodle basket for cooking noodles provided in this embodiment includes a cylindrical noodle basket main body 1 and a handle 2 installed on the noodle basket main body 1. The bottom of the noodle basket main body 1 is a through hole and A movable bottom plate 3 is provided on the through hole, the top of the main body 1 is an opening that can put noodles, the side wall of the main body 1 is porous mesh, and the movable bottom plate 3 is also in the shape of a leaking mesh. The movable bottom plate 3 is movably installed at the bottom of the main body 1 of the surface basket and is connected with the switch mechanism on the handle 2. When in use, the user can open the movable bottom plate 3 by holding the handle 2 and pressing the switch mechanism with the thumb. The noodles in the basket main body 1 can be directly dropped into the container from the bottom.

[0017] In the present invention, the opening method of the movable bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com