Fin, V-shaped heat exchanger and air conditioner

A technology for heat exchangers and air conditioners, applied in evaporators/condensers, space heating and ventilation details, household heating, etc., can solve problems such as heat exchangers prone to flakes, and achieve water blowing, structure Simple, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

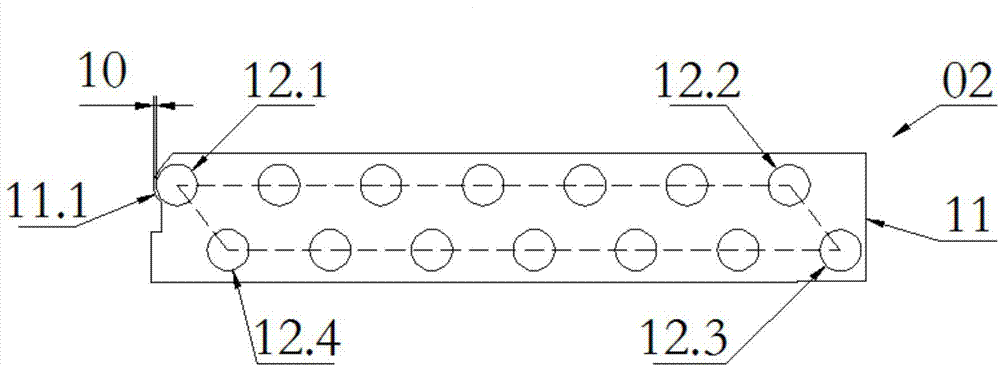

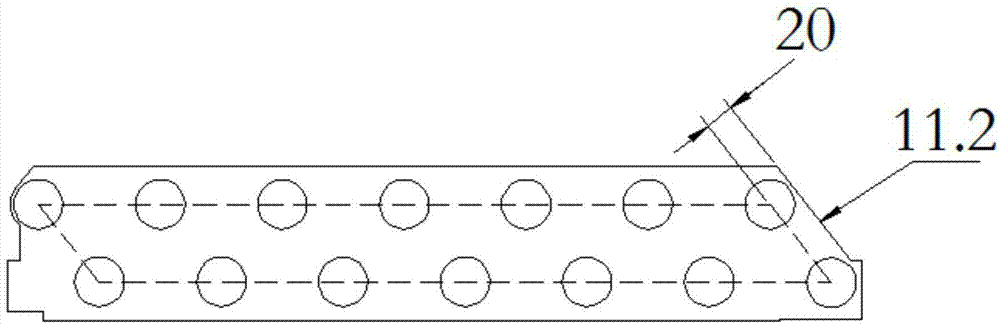

[0033] Such as figure 2 As shown, it is the first embodiment of the invention, which discloses a fin 02, which includes a strip-shaped fin body 11 and two rows of multiple refrigerant tubes arranged on the fin body 11 that are mutually offset. Through the holes, the fin body 11 in this example adopts a square structure. A first chamfer 11.1 is provided at the upper left corner of the fin body 11 .

[0034] A plurality of said refrigerant pipe passing holes form an oblique parallelogram. The upper left corner of the fin body 11 corresponds to the acute angle of the oblique parallelogram, the refrigerant pipe passage hole near the acute angle is the first refrigerant pipe passage hole 12.1, and the refrigerant pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com