Cylinder cover airtightness detector rear-blocking device

A technology of air tightness detection and cylinder head, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the problems of failing to achieve the detection effect, affecting the detection accuracy, and unfavorable blockage Problems such as head blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

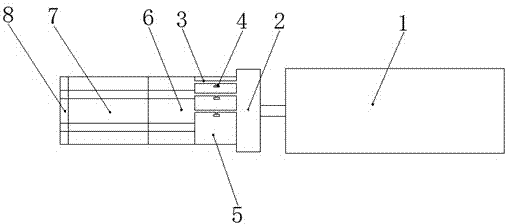

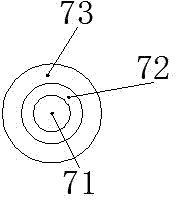

[0014] Such as figure 1 , figure 2 As shown, the present invention provides a rear plugging device for a cylinder head air tightness tester. The device is arranged on a workbench and includes a cylinder 1, a reversing valve 2, a connecting shell 5, an air chamber 6, a multi-purpose plug 7, and a reversing valve. One end of the valve 2 is connected to the piston rod of the cylinder 1, the other end of the reversing valve 2 is connected to the connecting shell 5, the connecting shell 5 is connected to the air chamber 6, and the air chamber 6 is connected to the multi-purpose plug 7, and the multi-purpose plug 7 The plugging end of the hole is provided with a silica gel cap 8, and the multi-purpose plug 7 is composed of a small plug 71, a middle plug 72, and a large plug 73. The small plug 71 is located at the innermost layer of the multi-purpose plug 7 and is cylindrical. The middle plug 72 fits on the outer surface of the small plug 71 and is a hollow cylinder, the large plug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com