Touch panel

A touch panel and touch unit technology, which is applied to instruments, electrical digital data processing, and data processing input/output processes, etc., can solve problems such as interpretation errors, the overall thickness is no longer uniform, and the quality of touch sensing is affected. , to achieve the same effect of sensitivity and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

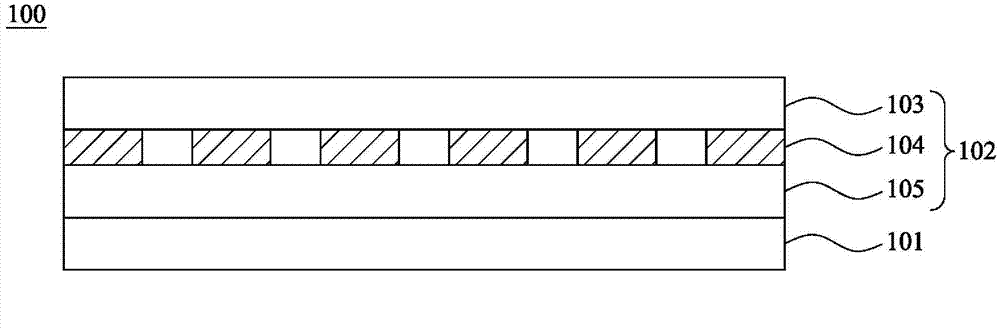

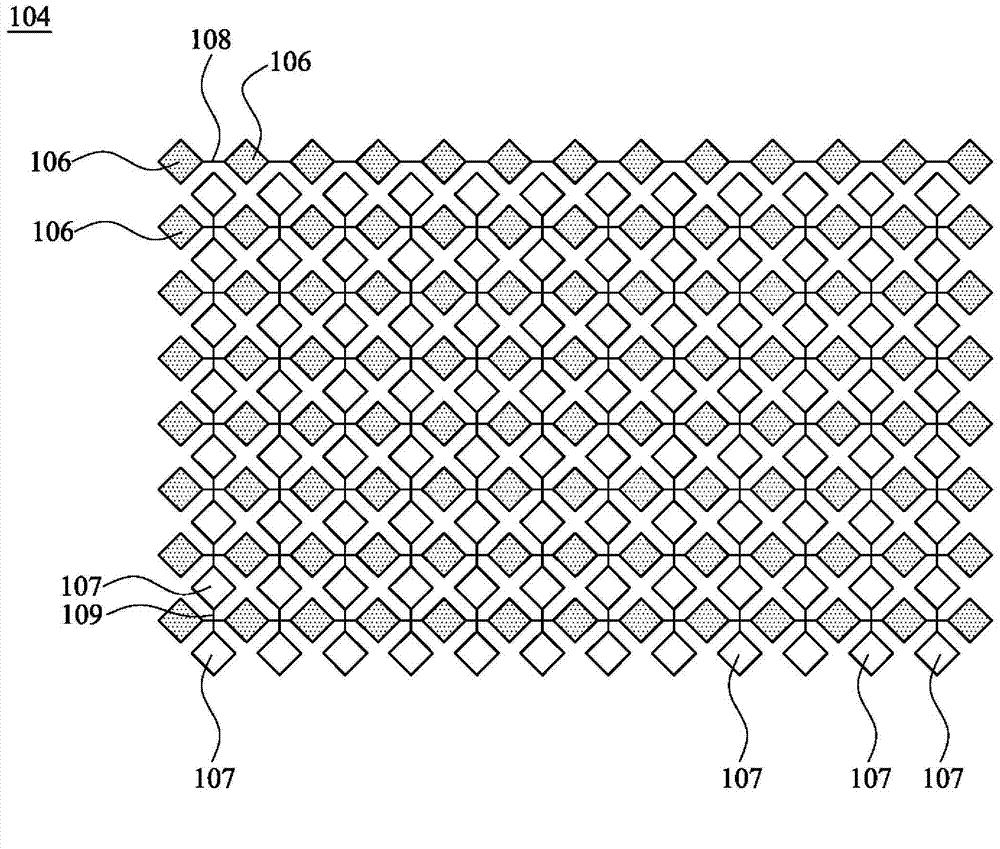

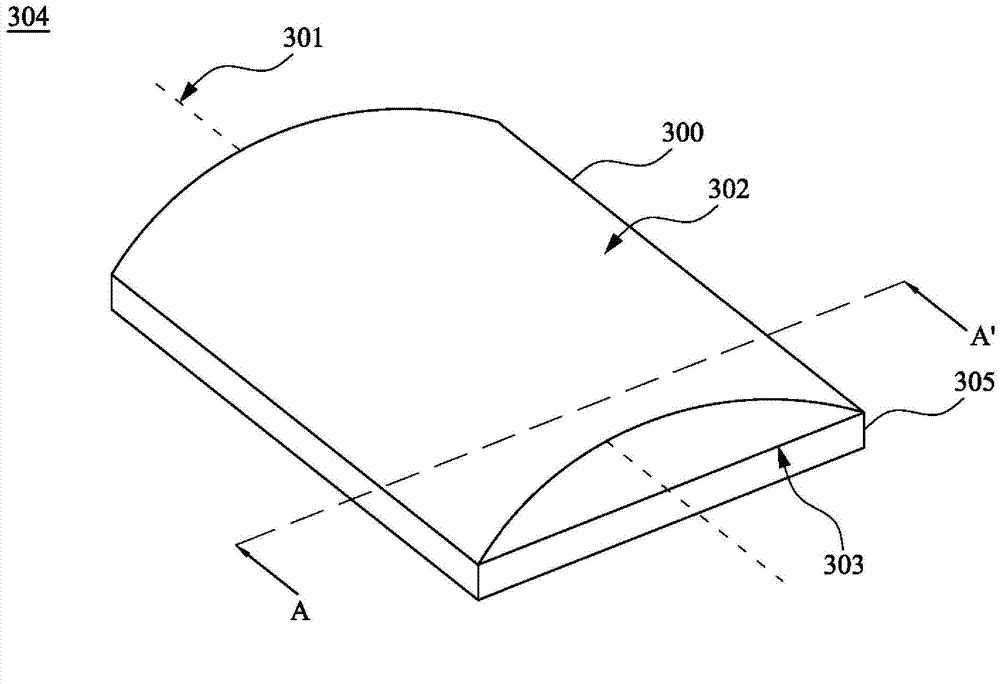

[0036] The following is a detailed description of preferred embodiments of the present invention with the accompanying drawings. The following description and drawings use the same reference numerals to indicate the same or similar elements, and repeated descriptions of the same or similar elements are omitted.

[0037] The traditional way of disposing the touch sensing layer is to adopt the sensing units with the same area, and distribute and arrange them on the transparent cover plate or the glass substrate with the same pitch. When the transparent cover is formed of a glass with different thickness (that is, the thickness is not uniform), because the vertical distance between each sensing unit and the upper surface of the transparent cover is different, different capacitance values will be formed, and in The touch sensing will cause interpretation errors and affect the quality of touch sensing. Therefore, the present invention corrects the area of each sensing unit and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com