Narrow bending device and method for a wide flat magnesium alloy pipe

A magnesium alloy and flat technology, which is applied in the field of narrow-direction bending devices for wide-width flat-shaped magnesium alloy pipes, can solve the problems of low bending yield and difficulty in narrow-direction bending of flat wide-width pipes, and achieve high yield and improve production efficiency And the effect of low yield and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

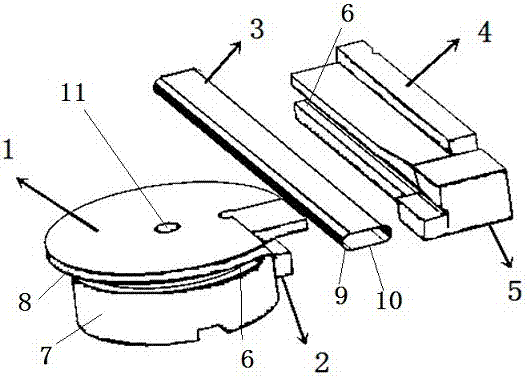

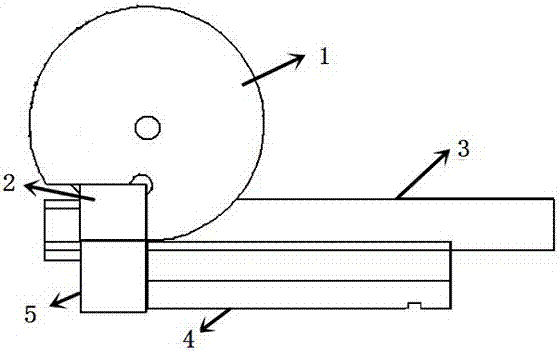

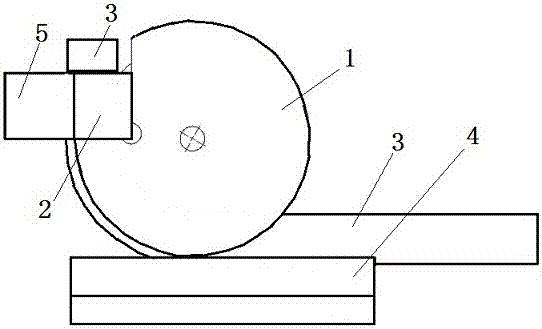

[0028] figure 1 As shown, a narrow bending device for a wide flat magnesium alloy pipe includes a rotating main mold 1, a sliding secondary mold 4, and a chuck 5, and the rotating main mold 1 is provided with an installation groove and a profile groove 6; A fixture 2 with a profile groove 6 is installed in the installation groove; the profile groove 6 matches the size of the profile workpiece; the chuck 5 is arranged in parallel with the sliding secondary mold 4, and the sliding secondary mold 4 is a cuboid with two steps. One of the steps is provided with a profile groove 6, which is a working head, and the other step is an installation head; the installation head is provided with an installation hole for connecting with hydraulic equipment.

[0029] The clamping head 5 is a cuboid with two steps, one of which is provided with a profile groove 6, which is a working head, and the other step is an installation head. The mounting head is provided with mounting holes for connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com