Three-wheel simple dual-cylinder engine cylinder body structure

An engine block, a simple technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of high production cost, short service life, difficult engine production, etc., achieve reasonable structure, reduce production cost, and solve difficult production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

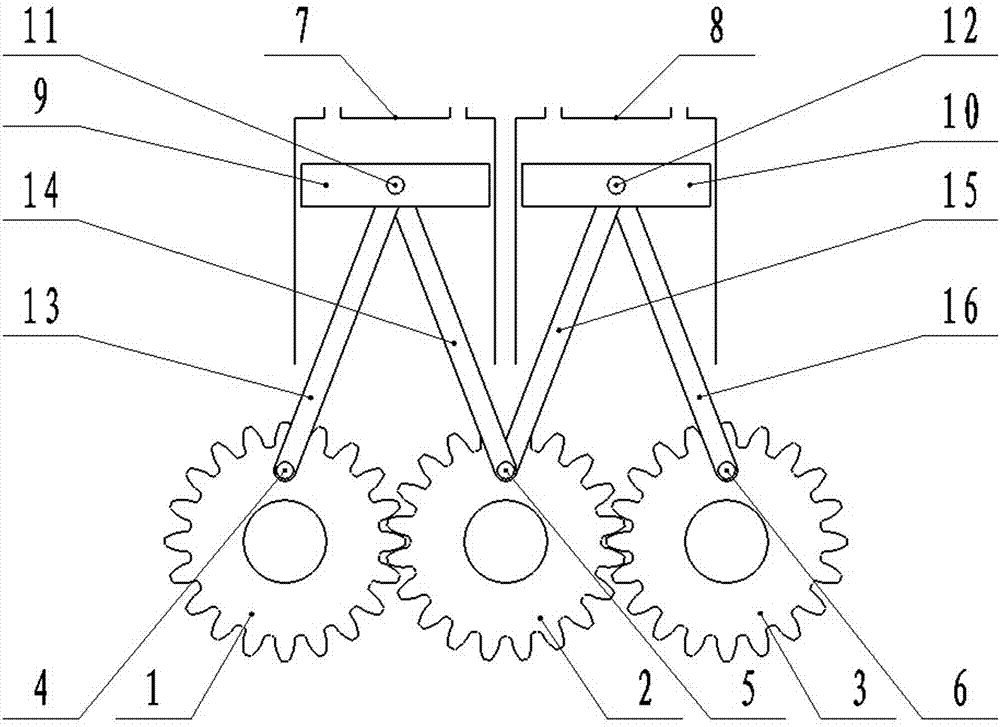

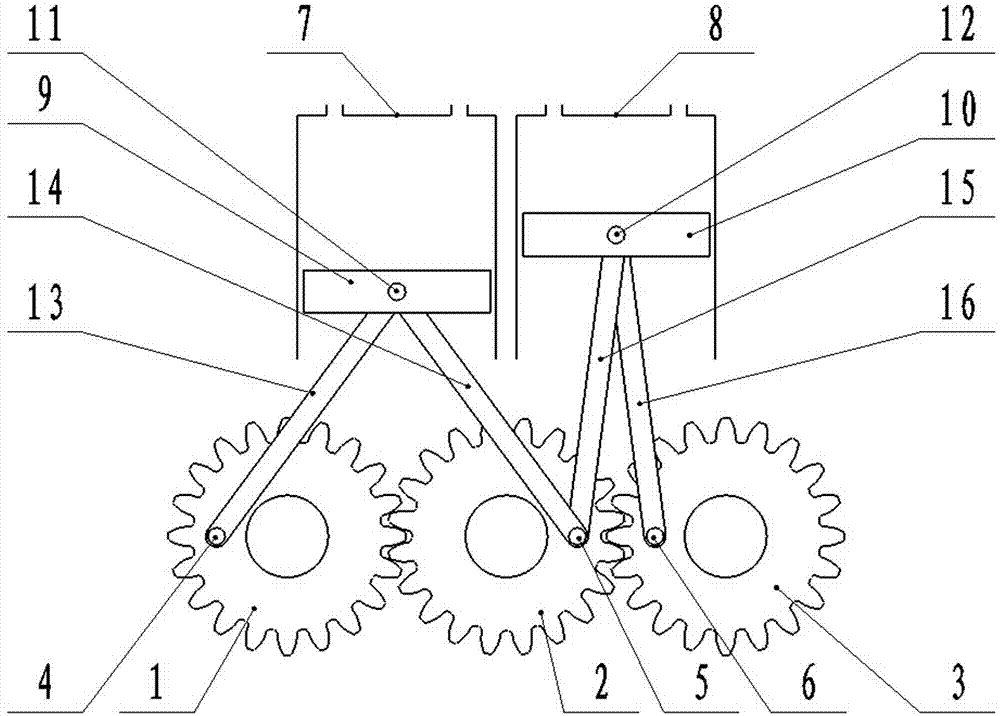

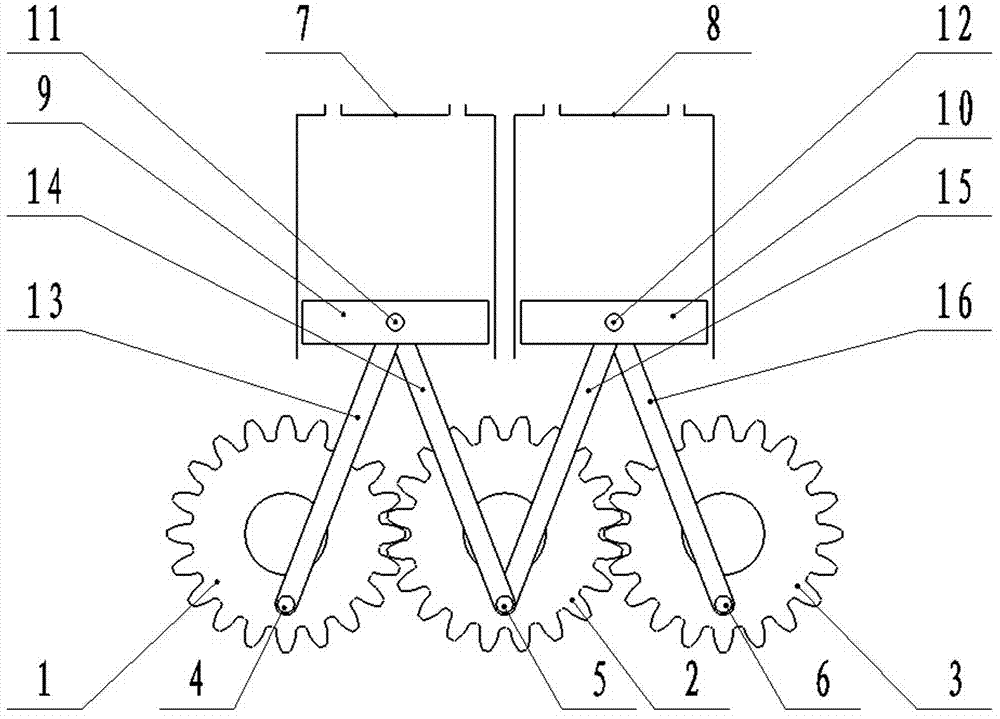

[0020] Three-wheel simple two-cylinder engine block structure, including first gear 1, second gear 2, third gear 3, first pin 4, second pin 5, third pin 6, first cylinder 7, Second cylinder 8, first piston 9, second piston 10, first piston pin 11, second piston pin 12, first connecting rod 13, second connecting rod 14, third connecting rod 15, fourth connecting rod 16;

[0021] Wherein, the diameter of the first gear 1, the diameter of the second gear 2, and the diameter of the third gear 3 are all equal; the circle center of the first gear 1, the circle center of the second gear 2, and the circle center of the third gear 3 are located on the same straight line; The first gear 1 and the second gear 2 mesh with each other; the second gear 2 and the third gear 3 mesh with each other; the end face edge of the first gear 1 is provided with a first pin hole; the end face edge of the second gear 2 is provided with a second pin hole; the end face edge of the third gear 3 is provided...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap