A compressor oil separator

A compressor oil and separator technology, used in machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of excessive lubricating oil, the separation effect of oil and gas does not reach the desired effect, etc., and increase the centrifugal separation rate. , The effect of enhancing oil separation efficiency and increasing the effective number of rotations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiment and accompanying drawing, set forth more details in the following description so as to fully understand the present invention, but the present invention can obviously be implemented in many other ways different from this description, Those skilled in the art can make similar promotions and deductions based on actual application situations without violating the connotation of the present invention, so the content of this specific embodiment should not limit the protection scope of the present invention.

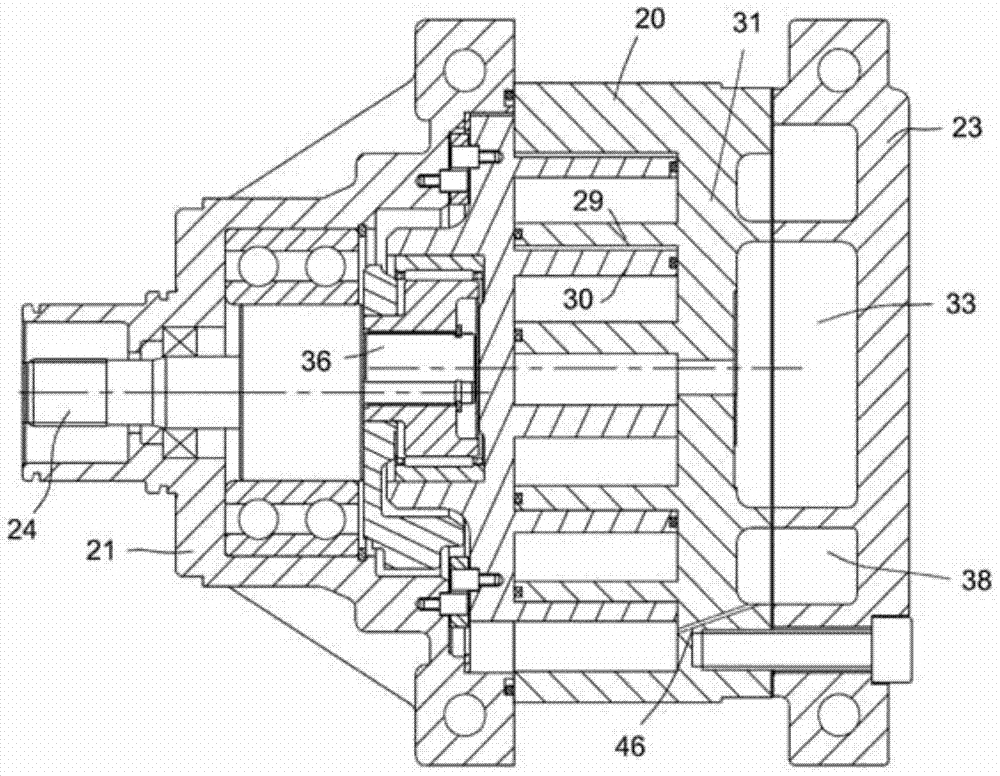

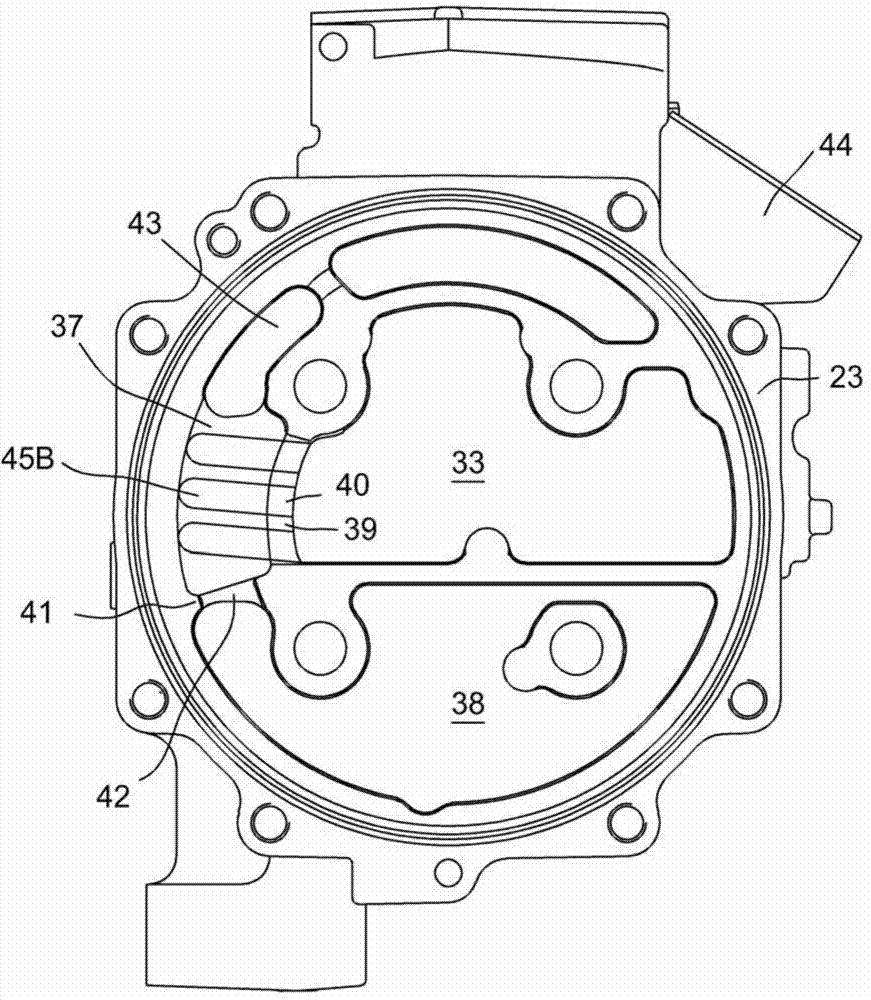

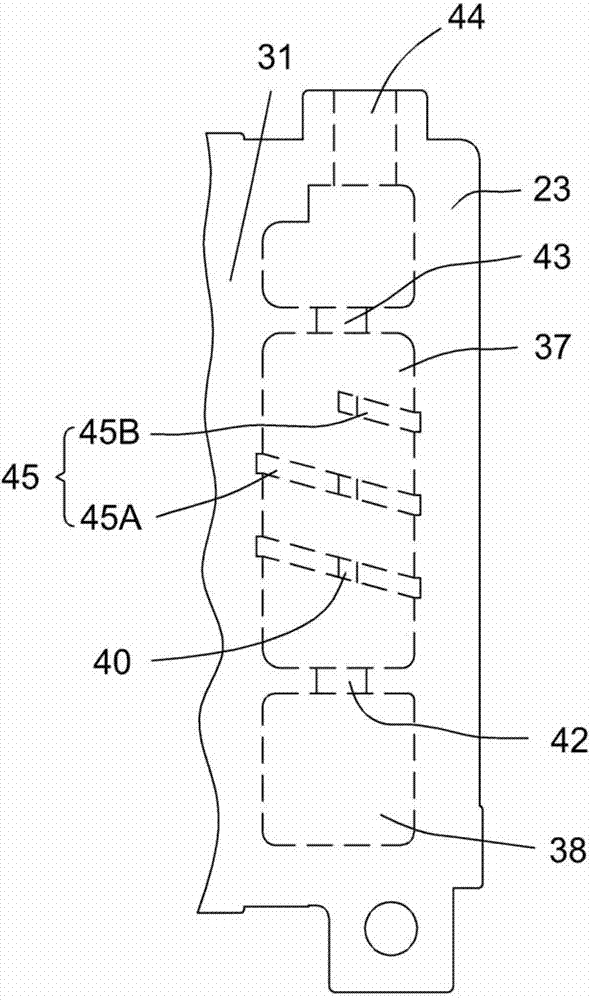

[0019] figure 1 A schematic diagram of a compressor in one embodiment of the invention is shown, which is a scroll compressor, but the invention is not limited thereto and may be other types of compressors. Figure 2 to Figure 3 The construction of the oil separator is shown. figure 2 Roughly correspond figure 1 Longitudinal sectional view of the middle and rear cylinder hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap