Fulcrum-equipped frictionless radial permanent magnetic suspension bearing

A magnetic suspension bearing, frictionless technology, applied to bearings, bearing components, shafts and bearings, etc., can solve the problems of complex structure of full permanent magnetic suspension radial bearings, small proportion of permanent magnetic suspension bearings, large bearing volume and weight, etc., to achieve The effect of simple structure, easy production and assembly, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

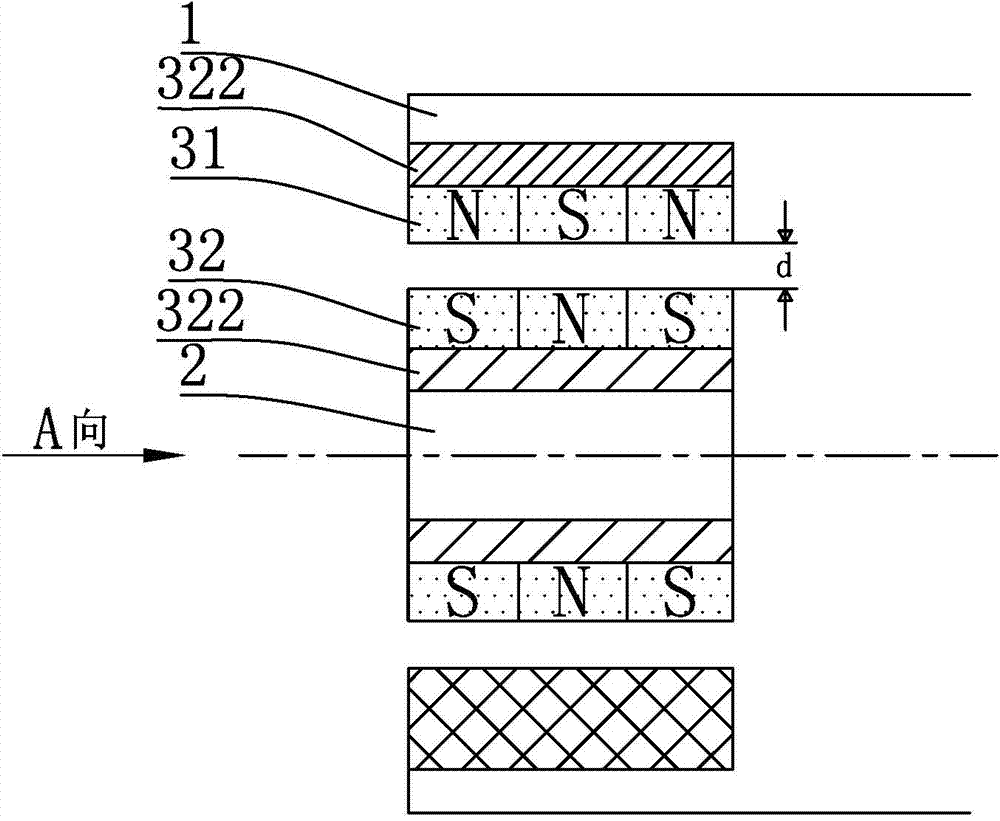

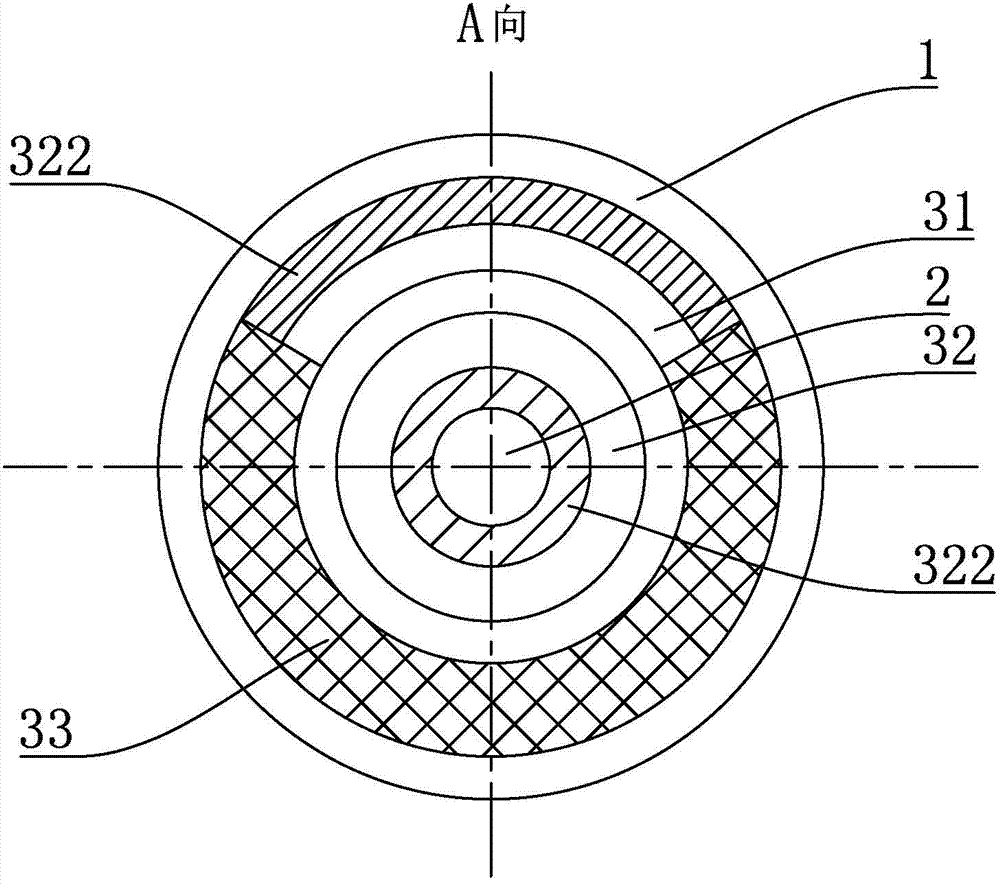

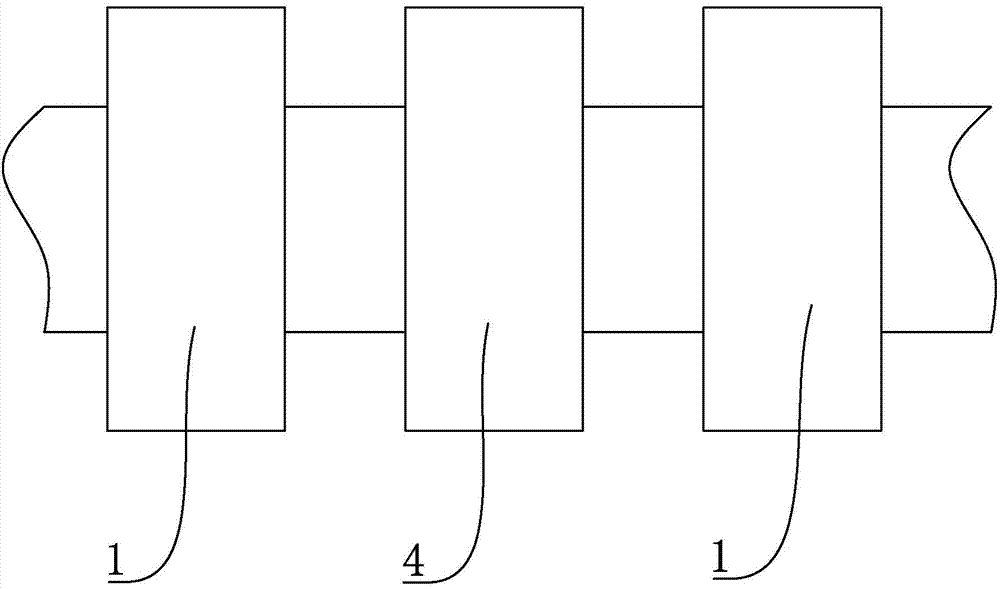

[0022] see figure 1 The fulcrum frictionless radial permanent magnetic suspension bearing of the present invention includes a support bearing 4 arranged on the horizontal shaft as the rotor 2 as a support fulcrum, and a permanent magnetic suspension bearing arranged on the horizontal shaft 2 with an axial distance from the support bearing 4 3. The permanent magnetic suspension bearing 3 includes a stator pull-push magnet 31 arranged on the stator through a magnetically permeable base 322 and correspondingly arranged on the rotor 2 through a ring-shaped magnetically permeable base 322, having a radial gap d with the stator pull-push magnet 31 and A rotor pull-push magnet 32 forming an axial pull-push magnetic circuit, the rotor pull-push magnet 32 is composed of two or more ring-shaped permanent magnets arranged in close contact with each other in the axial directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com