A Multiple Boiling Exhaust Method Applicable to Pulsating Heat Pipes

A technology of pulsating heat pipes and exhaust ports, which is applied in the field of heat pipe manufacturing, can solve the problems of insufficient vacuum degree and achieve the effects of low cost, high controllable precision, and precise control of liquid filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

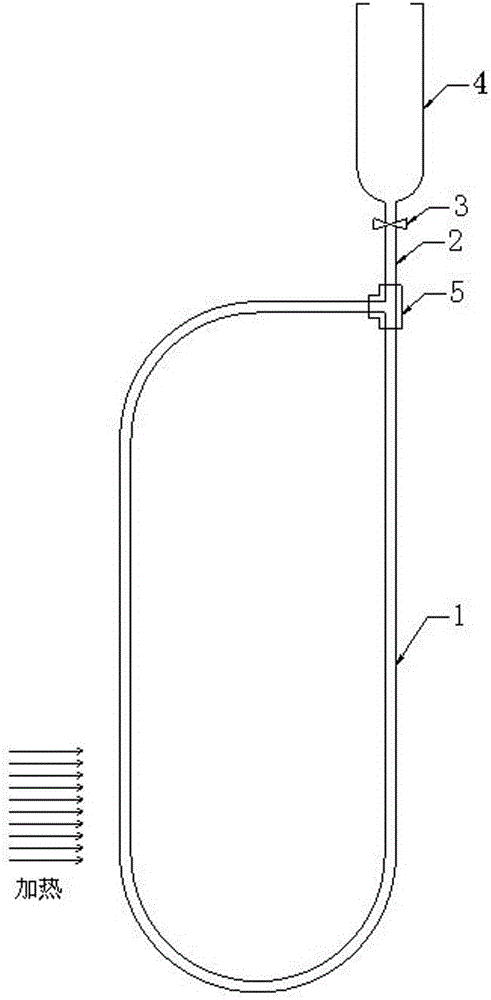

[0029] Such as figure 1 As shown, a multiple boiling exhaust method suitable for pulsating heat pipes, the head and tail ends of the pulsating heat pipe 1 form a circuit through the three-way joint 5, and the other interface of the three-way joint 5 is sequentially connected to the liquid-filled drain Air port 2, valve 3 and liquid reservoir 4 with scale, the pulsating heat pipe 1 can include multiple circuits, figure 1 Only one of the loops is drawn in , which does not mean that there is only one loop. Include steps:

[0030] (1) Primary exhaust: place the pulsating heat pipe 1 vertically, with the liquid-filled exhaust port 2 on top, open the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com