Three-roller integrated load roller pin optic elastohydrodynamic tester

A needle photoelastic flow and testing machine technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve problems such as less research, achieve the effect of increasing test content, uniform distribution, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are described in detail as follows in conjunction with the accompanying drawings:

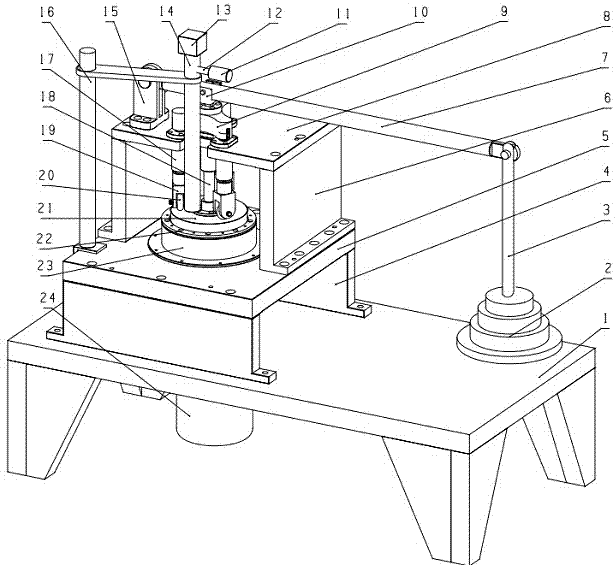

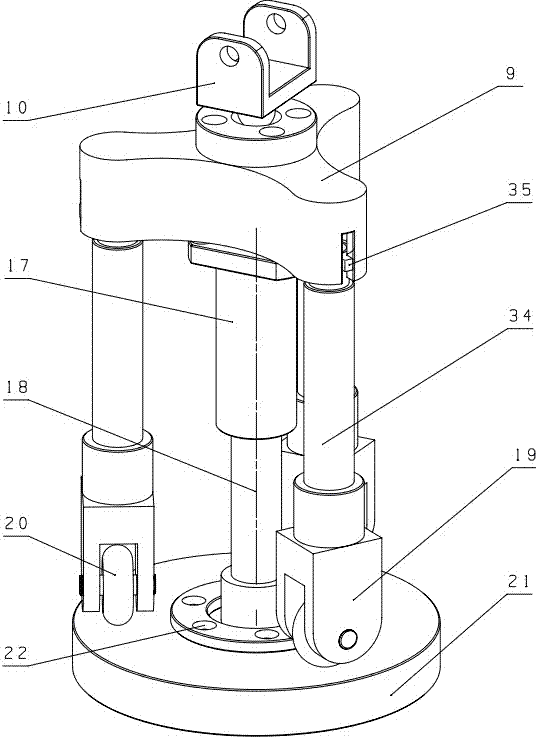

[0019] like figure 1 As shown, a three-roller integrally loaded needle photoelastic hydrodynamic testing machine includes a machine base 1, a base support plate 4, a base 5, a beam support plate 6, a beam 8, an optical interferometric measurement system, a loading system and a transmission mechanism; The base 1 is located at the bottom, the base support 4 is connected to the base 1 by screws, the base 5 and the beam support 6 are installed on the top of the base support 4, and the optical interferometric measurement system is fixed on the base 5. , the loading system is installed on the beam 8, and the transmission mechanism is connected by screws and is seated on the machine base 1.

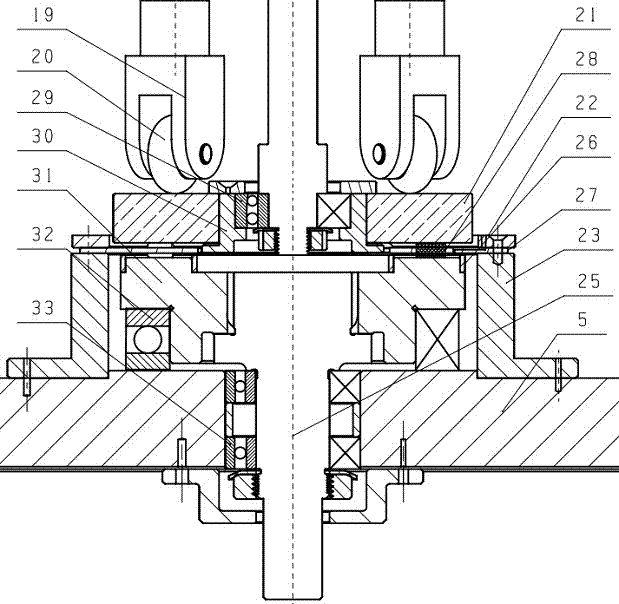

[0020] The optical interferometric measurement system includes a monochromatic light source 11, a narrow-band filter 12, a high-speed CCD 13, a microscope 14, a micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com