Low-pressure rotating nozzle water sprinkler

A water diffuser and rotating technology, applied in spraying devices, spraying devices with movable outlets, etc., can solve the problems of difficult large-scale promotion, high cost, complex damping structure, etc., and achieve favorable promotion and use, stable hydraulic performance, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

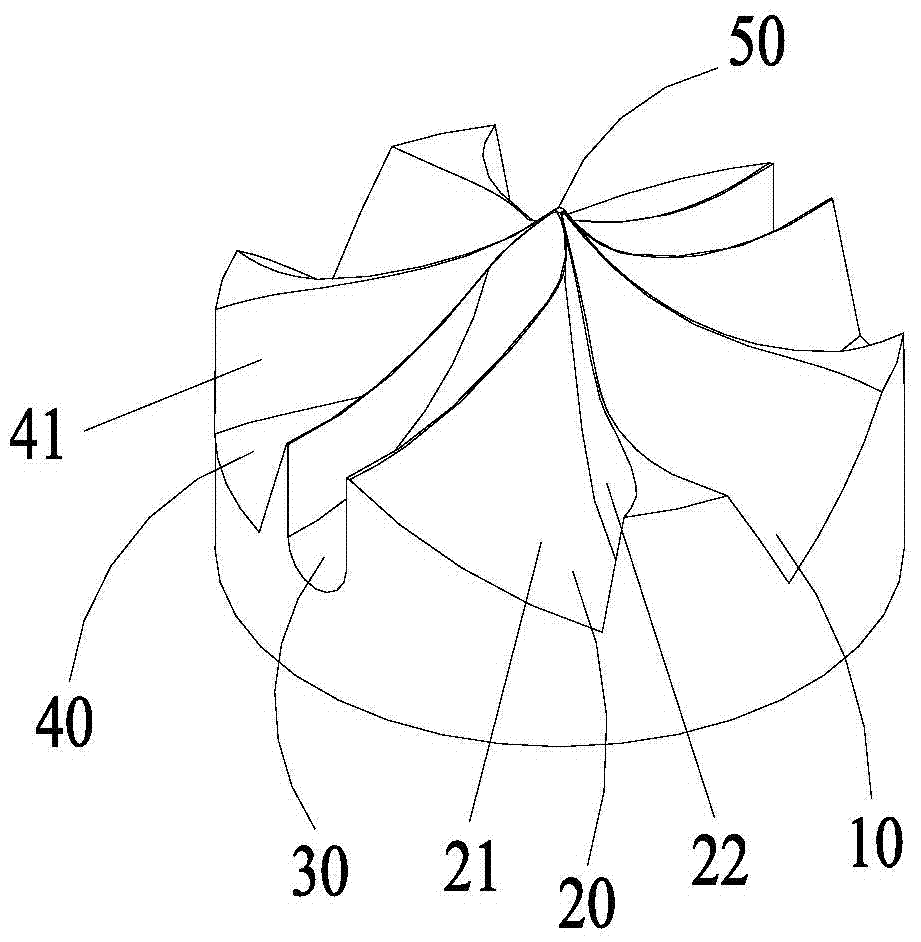

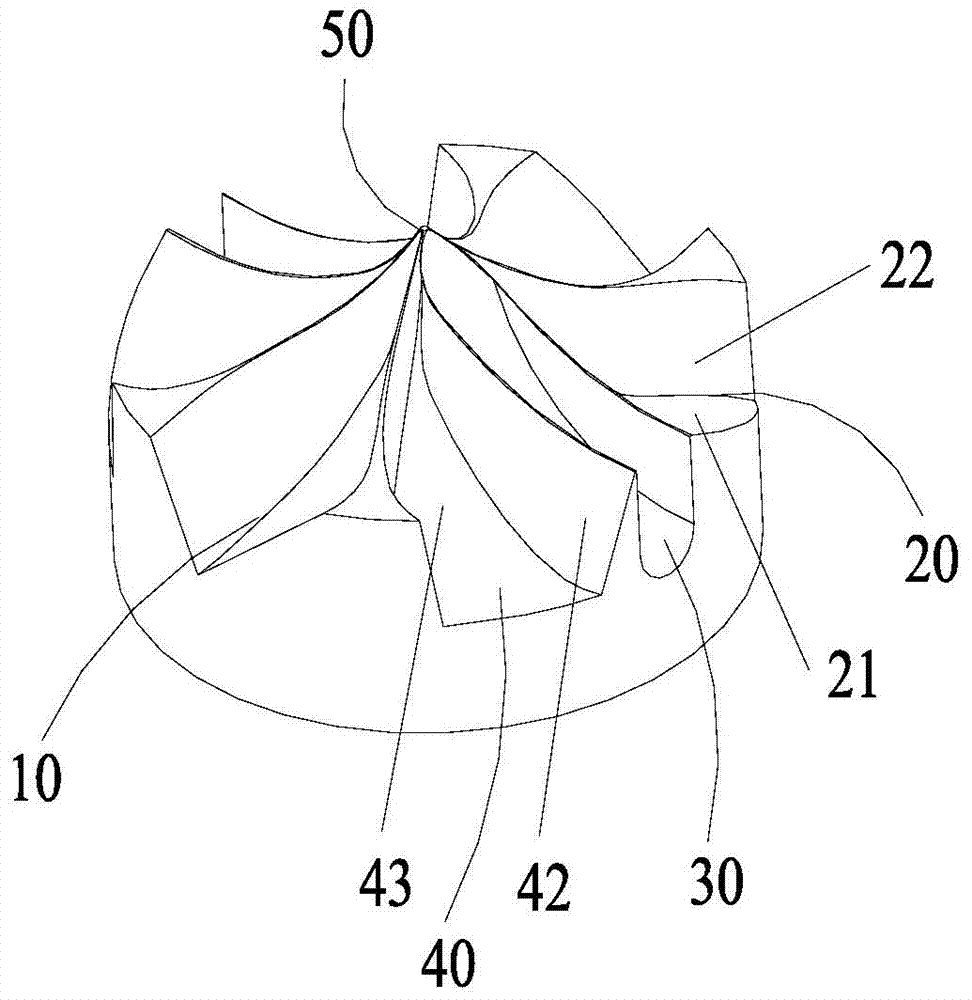

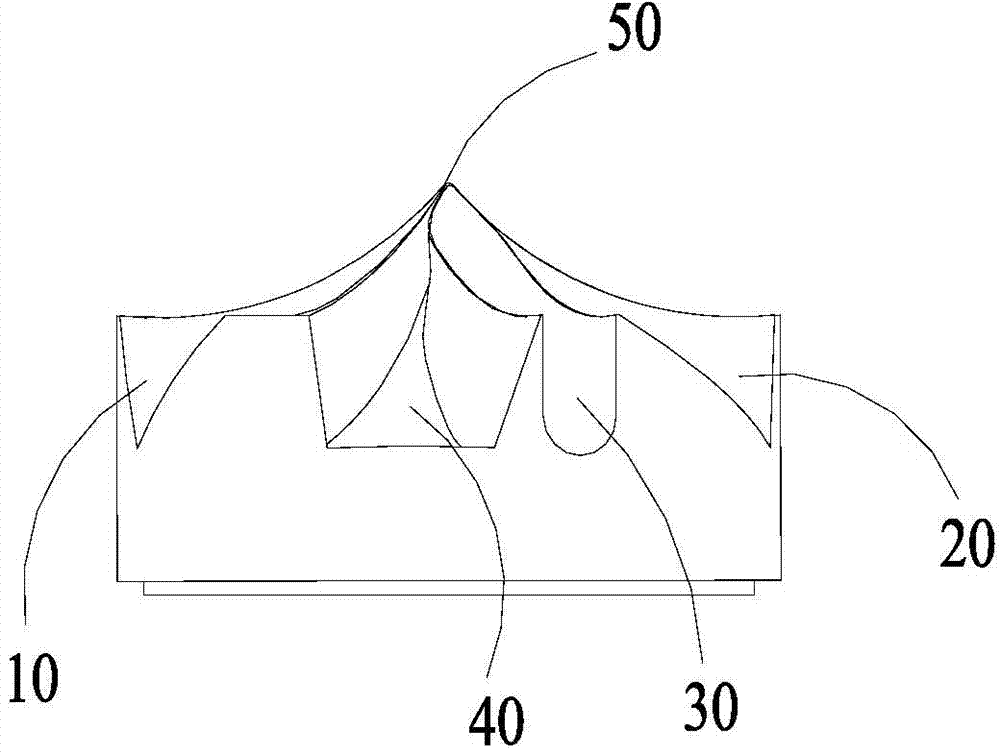

[0044] refer to Figure 1 to Figure 4 , the low-pressure rotary sprinkler water tray of the present invention is disc-shaped, including an upper surface and a lower surface, and one end of the lower surface is provided with a blind hole, which is fixed on the damper by means of a pin hole. Of course, other ways of connection may also be used, and the present invention is not limited thereto.

[0045] The upper surface of the low-pressure rotary spray head water tray of the present invention has a central part 50 and a plurality of flow channel groups. Wherein, the central portion 50 is located at the center of the upper surface and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com