Mechanical regulating device for big spring at the lower part of cart-type coke oven

A technology of adjusting device and large spring, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low adjustment accuracy, high temperature, high labor intensity, etc., and achieve the effect of convenient matching of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

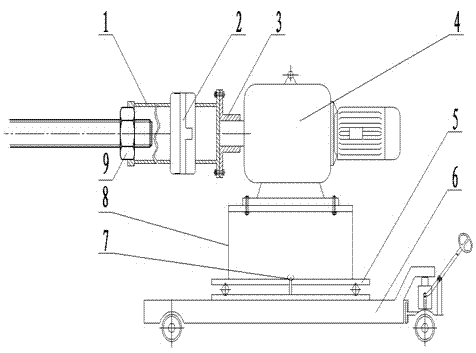

[0013] Such as figure 1 As shown, the lifting mechanism includes a liftable trolley 6, the liftable trolley 6 is hinged with a rotating disk 5, the support mechanism includes a bracket 8, the liftable trolley 6 is a common commercial trolley, and the liftable trolley 6 passes through the positioning shaft 7 Hinged with rotating disk 5, by rotating disk 5 around the positioning axis 7 can be on the trolley 180 0 Free rotation; the bracket 8 is fixed on the rotating disk 5 and rotates with the rotating disk; the adjustment mechanism includes a reducer 4, a flange coupling 3, and a cross coupling 2, and the reducer 4 passes through the flange type The coupling 3 and the cross coupling 2 are connected with the sleeve 1; the motor 4 of the pinwheel reducer of the adjustment mechanism is equipped with a 5-6 meter temperature-resistant cable and plug, and the auxiliary electric control switch box is installed in a suitable place on the trolley. In addition, slide wire cables and exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com