Coordination location device for automatic butt joint assembly of large thin-wall cylindrical members

An automatic docking and positioning device technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of feature change of measurement feature points, damage to parts to be adjusted, and insufficient positioning accuracy, so as to ensure that features remain unchanged, The effect of reducing assembly internal stress and improving butt joint accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

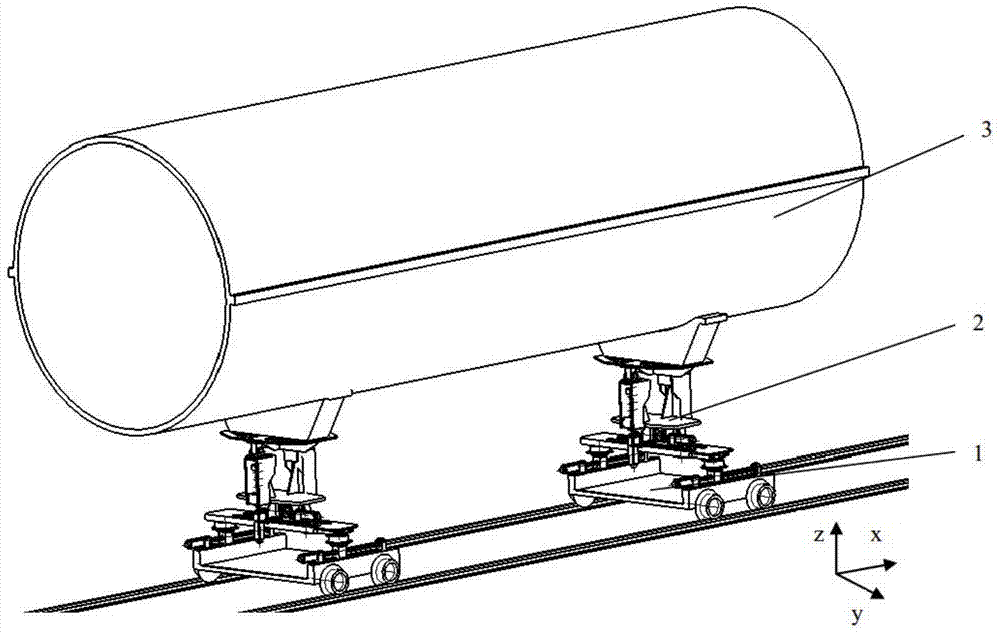

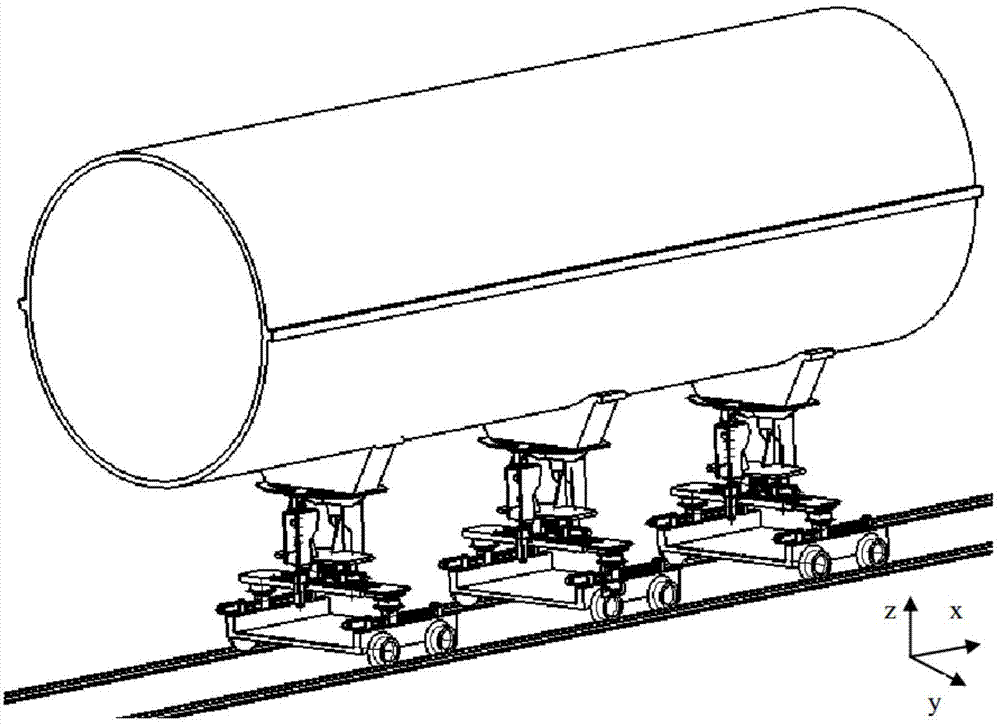

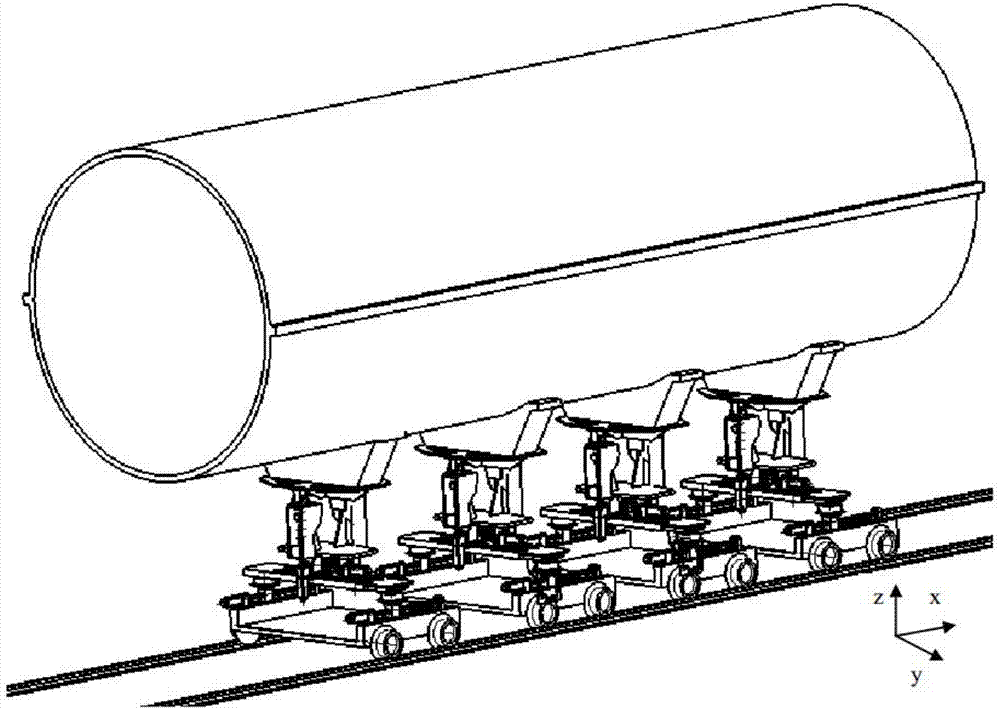

[0028] Such as Figure 1~4 As shown, this embodiment includes: at least two sets of positioning mechanisms 2 slidably arranged on the ground track 1 and the attitude-adjusting member 3 connected to the positioning mechanisms 2, wherein:

[0029] Such as Figure 4 As shown, the positioning mechanism 2 includes: a rail car chassis 4 and a swing platform mechanism 5, a lateral attitude adjustment mechanism 6, a pitch platform mechanism 7 and a component rotation mechanism arranged on the rail car chassis 4 in sequence from bottom to top. 8, of which:

[0030] Such as figure 1 As shown, when two sets of positioning mechanisms 2 are used, the two sets of positioning mechanisms form a coordinated positioning device, wherein: two swing platform mechanisms 5, two lateral attitude adjustment mechanisms 6 and one pitch platform mechanism 7 in each positioning mechanism 2 Five active kinematic pairs are formed, at least one of the component rotation mechanisms 8 of the two positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com