Design method of tire mould

A technology of tire mold and design method, applied in the field of tire mold, can solve the problems of waste of investment, no application value, high cost, etc., and achieve the effect of reducing manufacturing cost, flexible combination, and convenient selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

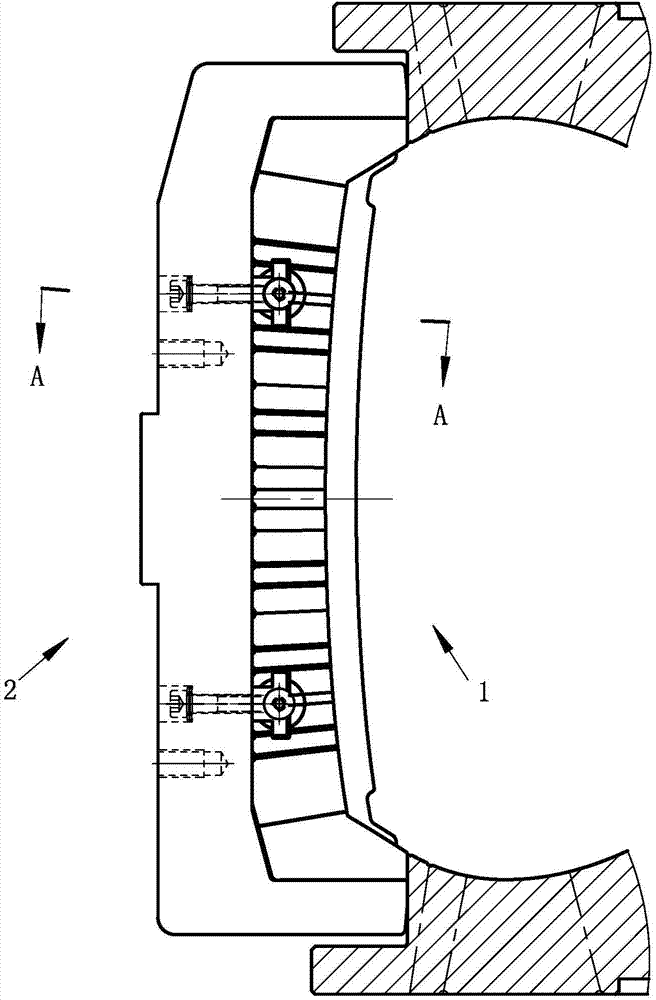

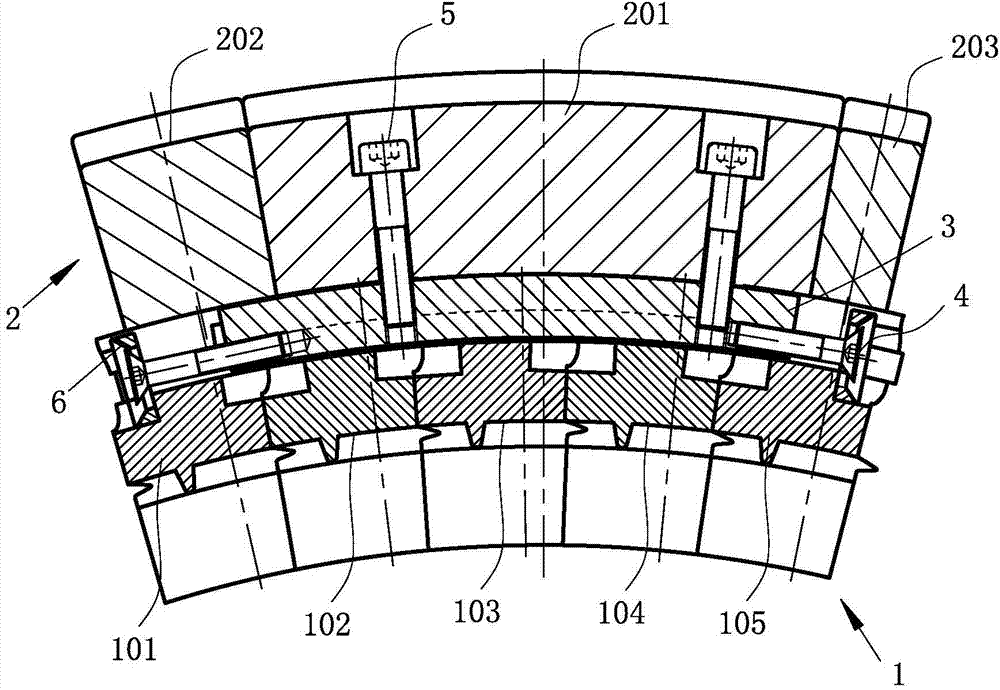

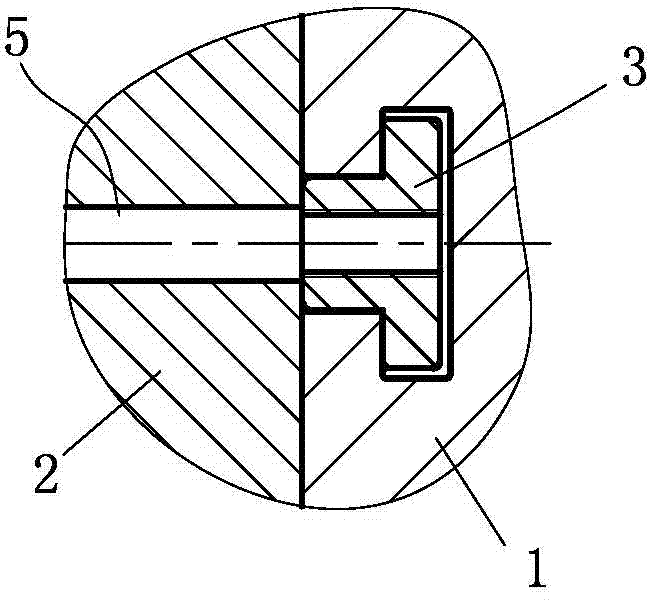

[0025] Such as figure 1 , figure 2 and image 3 Commonly shown, the present invention provides a kind of design method of tire mold, comprises the pitch unit of M kind of pitch, and every kind of pitch unit is all provided with several, selects N kind of pitch unit to arrange and combine to form tire mold ( N≤M), each pitch unit can be interchanged arbitrarily in the circumferential position, and all the selected pitch units form a complete tire pattern when they are molded together, and can be combined into a tire mold by selecting pitch units with different pitches, or Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com