Triangular crawler wheel device

A triangular crawler and crawler technology, applied to tracked vehicles, transportation and packaging, motor vehicles, etc., can solve problems such as difficult steering, inflexibility, and large contact area, and achieve fast moving speed, stable driving, and flexible control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

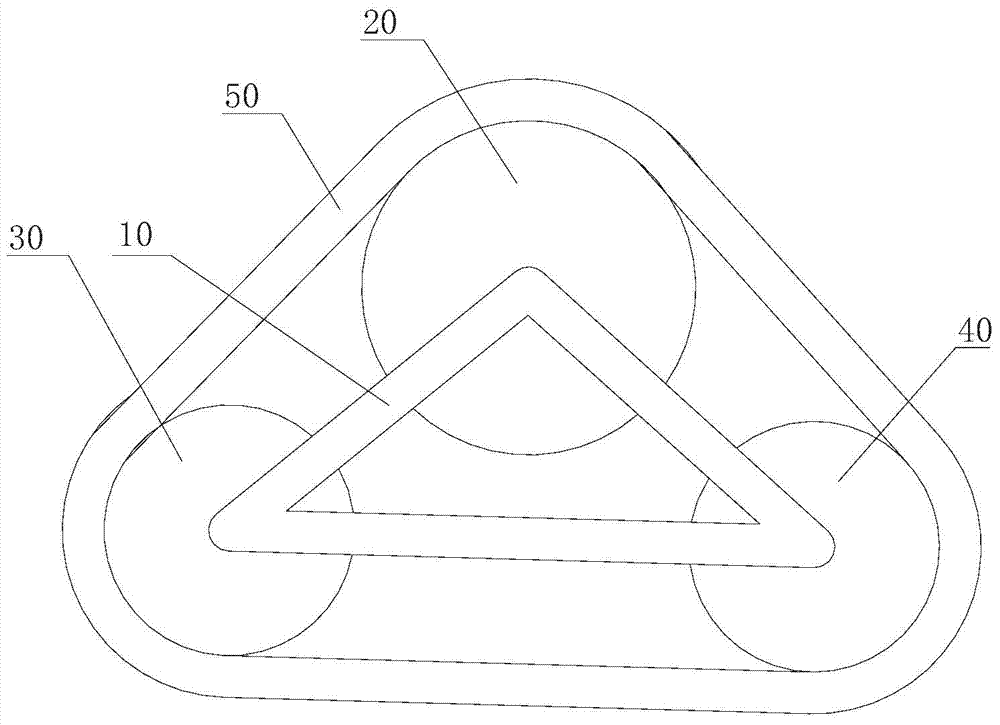

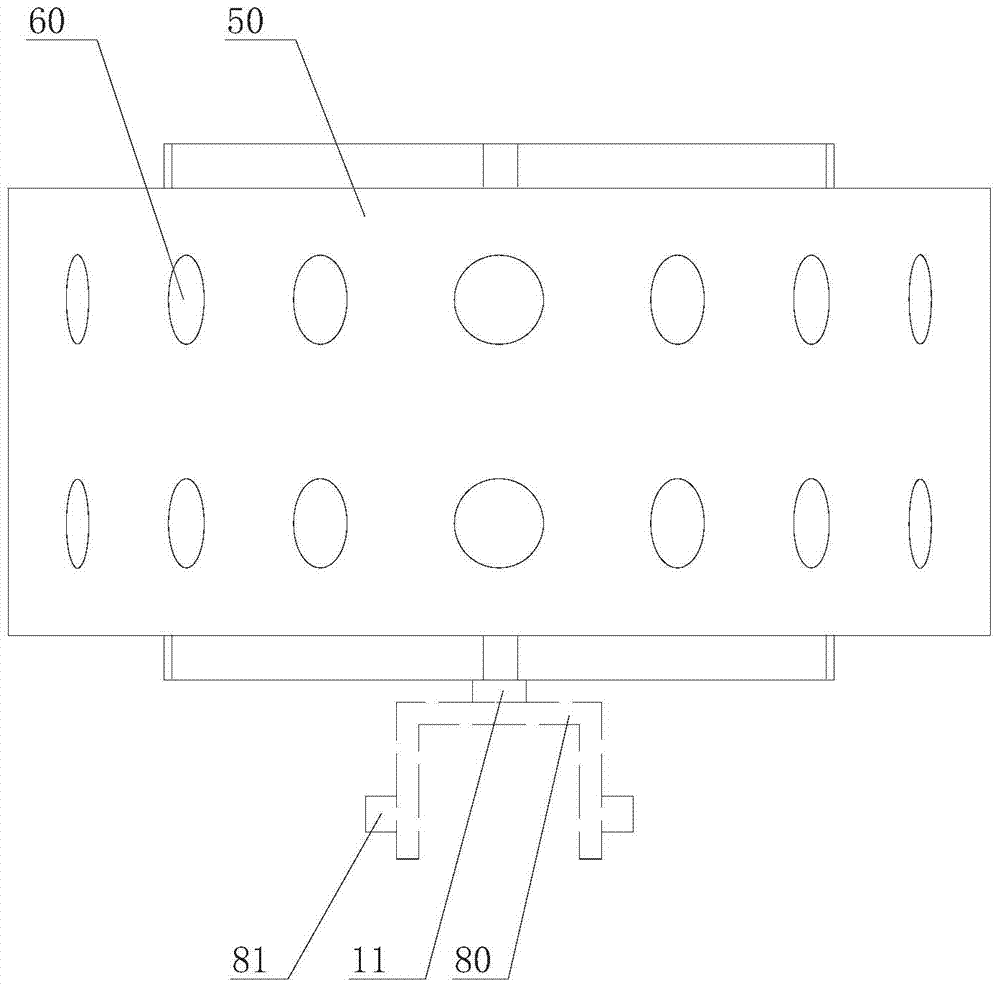

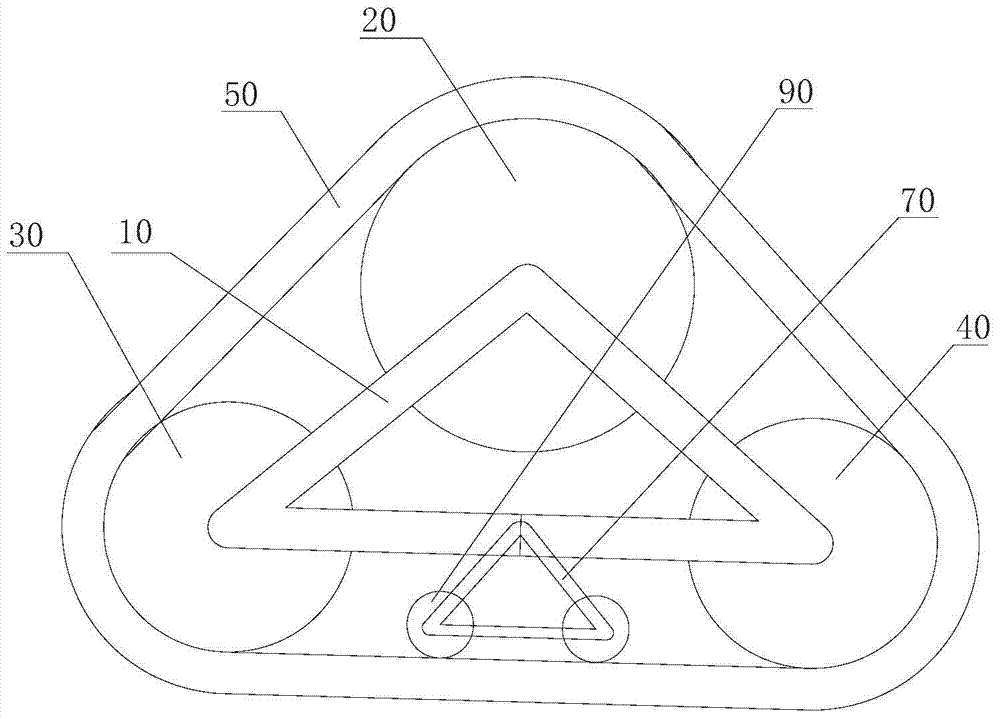

[0020] In order to achieve the purpose of the present invention, as Figure 1 to Figure 2 As shown, a triangular track wheel device is provided in one of the embodiments of the present invention, including a triangular bracket 10, a driving wheel 20, a guide wheel 30, a tensioning wheel 40, a crawler belt 50 and a plurality of magnetic parts 60, and the triangular bracket 10 is vertically arranged, the driving wheel 20, the guide wheel 30, and the tension wheel 40 are respectively arranged on the three vertices of the triangular support 10 and the drive wheel 20 is positioned above the guide wheel 30, the tension wheel 40, and the crawler belt 50 surrounds the drive wheel 20. The circumferential surfaces of the guide wheel 30 and the tensioning wheel 40 are connected in transmission, and the magnetic parts 60 are evenly arranged on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com