Bicycle brake oil tube concealing structure

A bicycle and oil pipe technology, applied in bicycle accessories, bicycle brakes, etc., can solve the problems of oil leakage, fracture, and the overall appearance is not simple enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

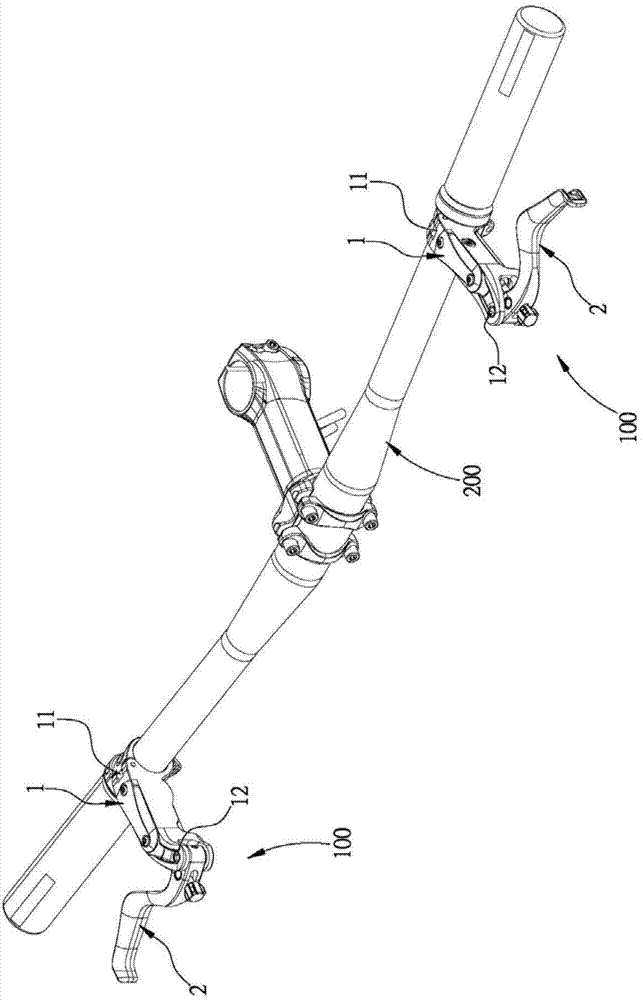

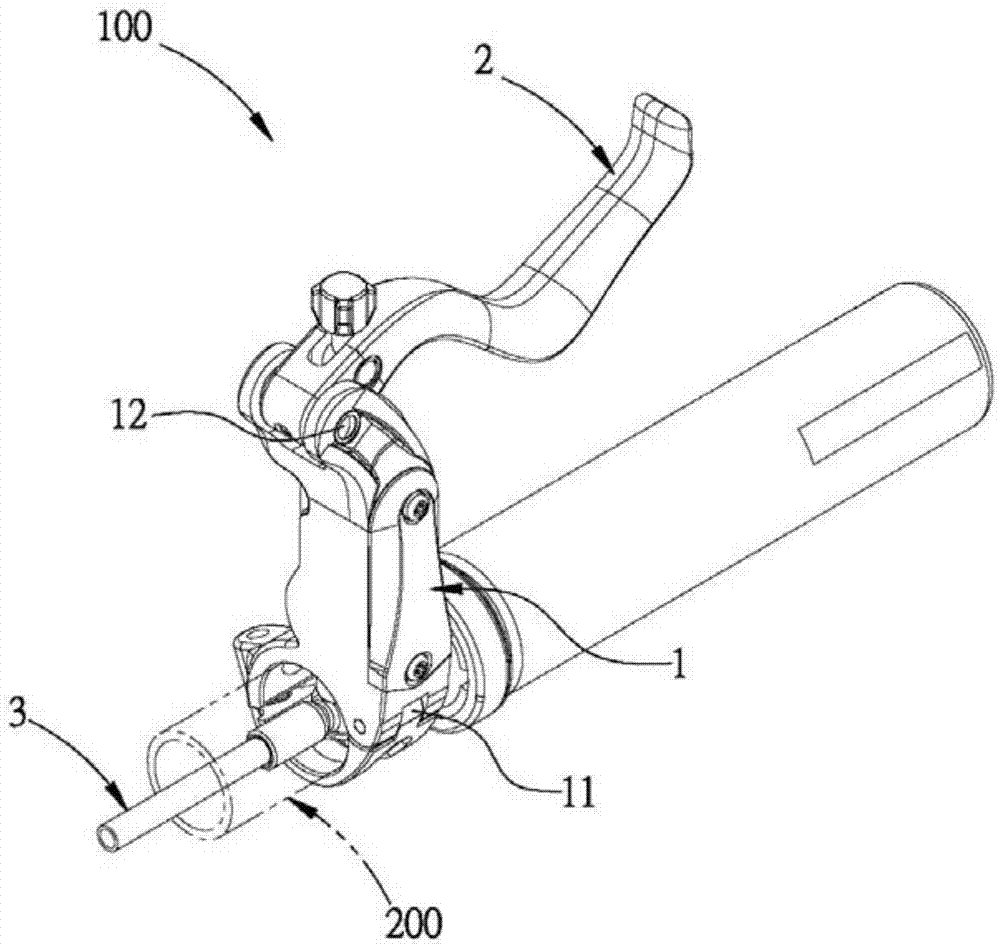

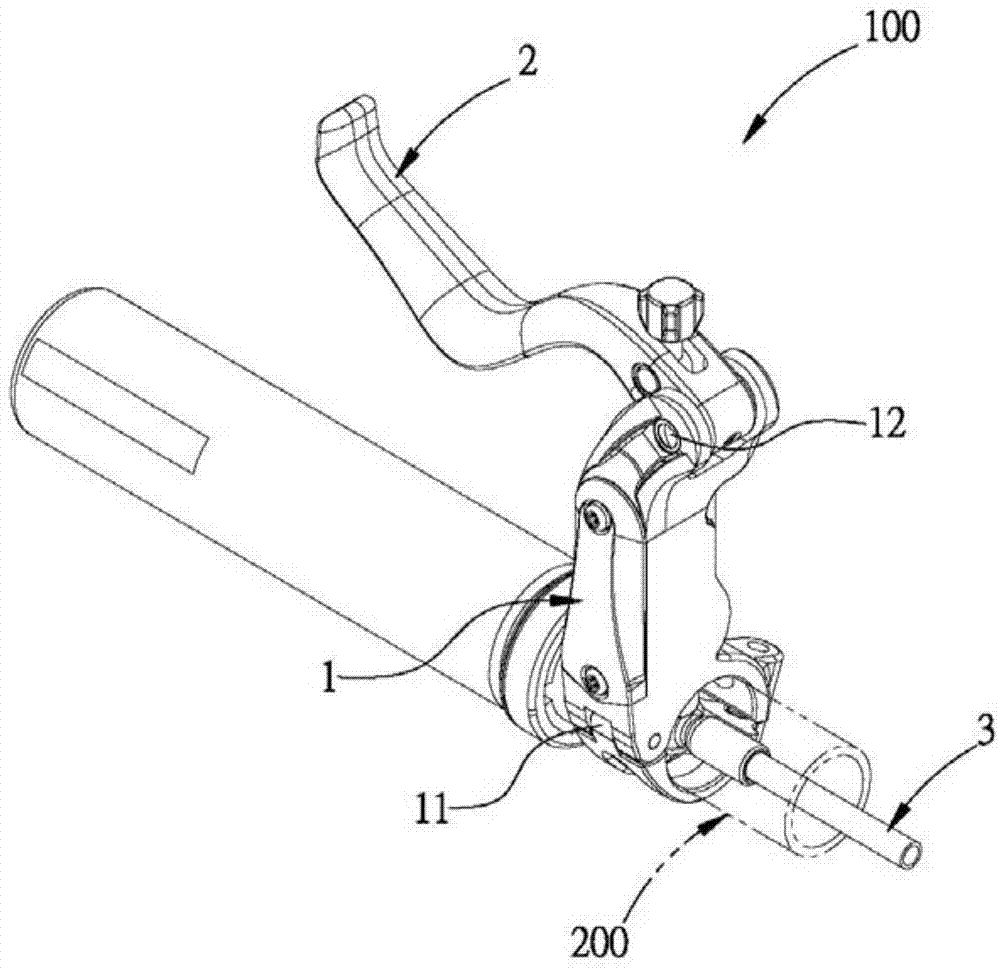

[0021] see Figure 1 to Figure 8 As shown, the hidden structure 100 for bicycle brake oil pipes of the present invention includes a brake body 1 , a handle 2 , and an oil pipe 3 .

[0022] The brake body 1 can have a first end 11 and a second end 12 oppositely arranged, and the first end 11 of the brake body 1 is connected to a predetermined position of a handlebar 200 of a bicycle (not shown); figure 2 In other words, the brake body 1 is arranged at the left end adjacent to the handle pipe 200; image 3 Specifically, the brake body 1 is disposed adjacent to the right end of the handle pipe 200 .

[0023] Wherein, the brake body 1 can be a common butterfly hydraulic cylinder.

[0024] Wherein, the handle 2 can be pivotally connected with the second end 12 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com