A kind of gooseneck groove, the manufacturing method of gooseneck groove, container underframe and container

A gooseneck groove and container technology, applied in the field of support parts, can solve the problems that the gooseneck groove cannot meet the core demands of customers, the gooseneck groove has poor resistance to residual deformation, and affects the service life of containers, etc., and achieves high resistance to residual deformation. Widely applicable and easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following will further explain the gooseneck groove, the manufacturing method of the gooseneck groove, the container chassis and the container according to the present invention in conjunction with the description of the drawings and specific embodiments, but the explanation does not constitute a technical basis for the present invention. Improper limitation of the program.

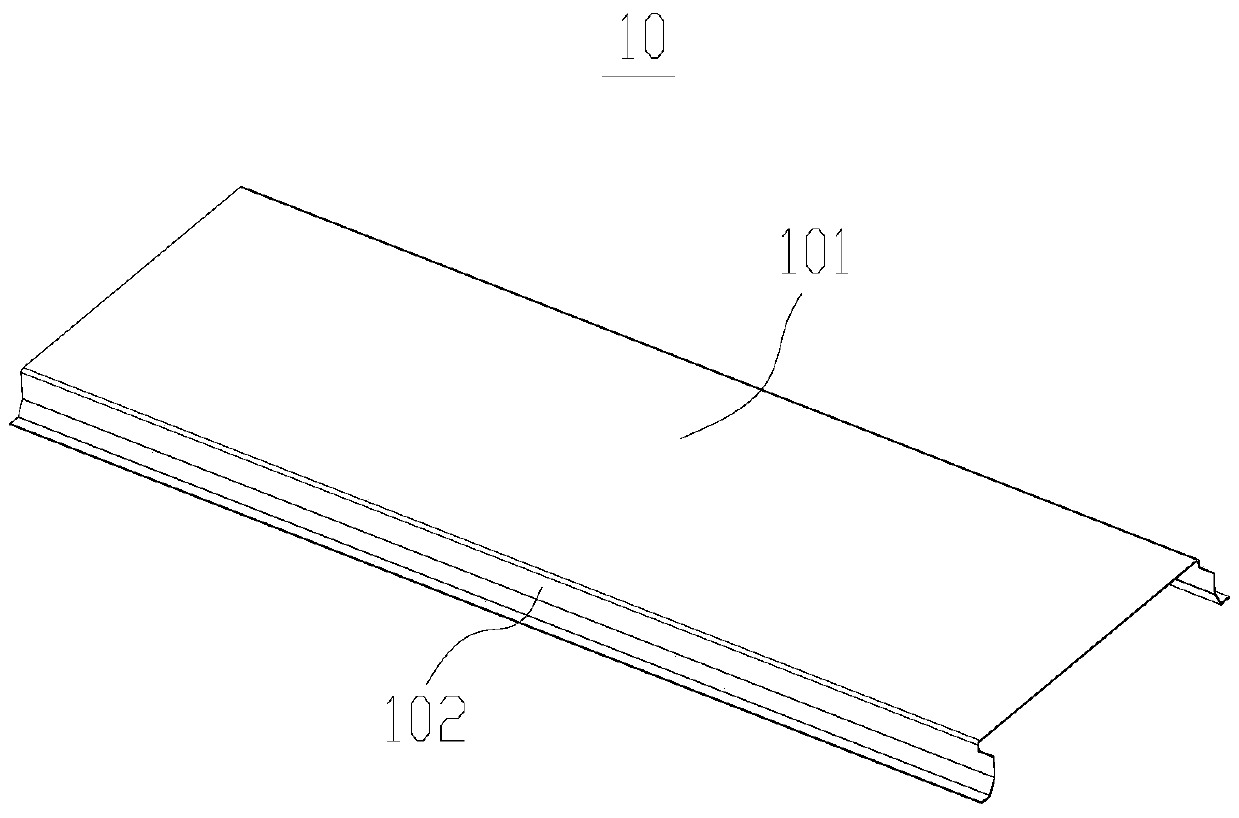

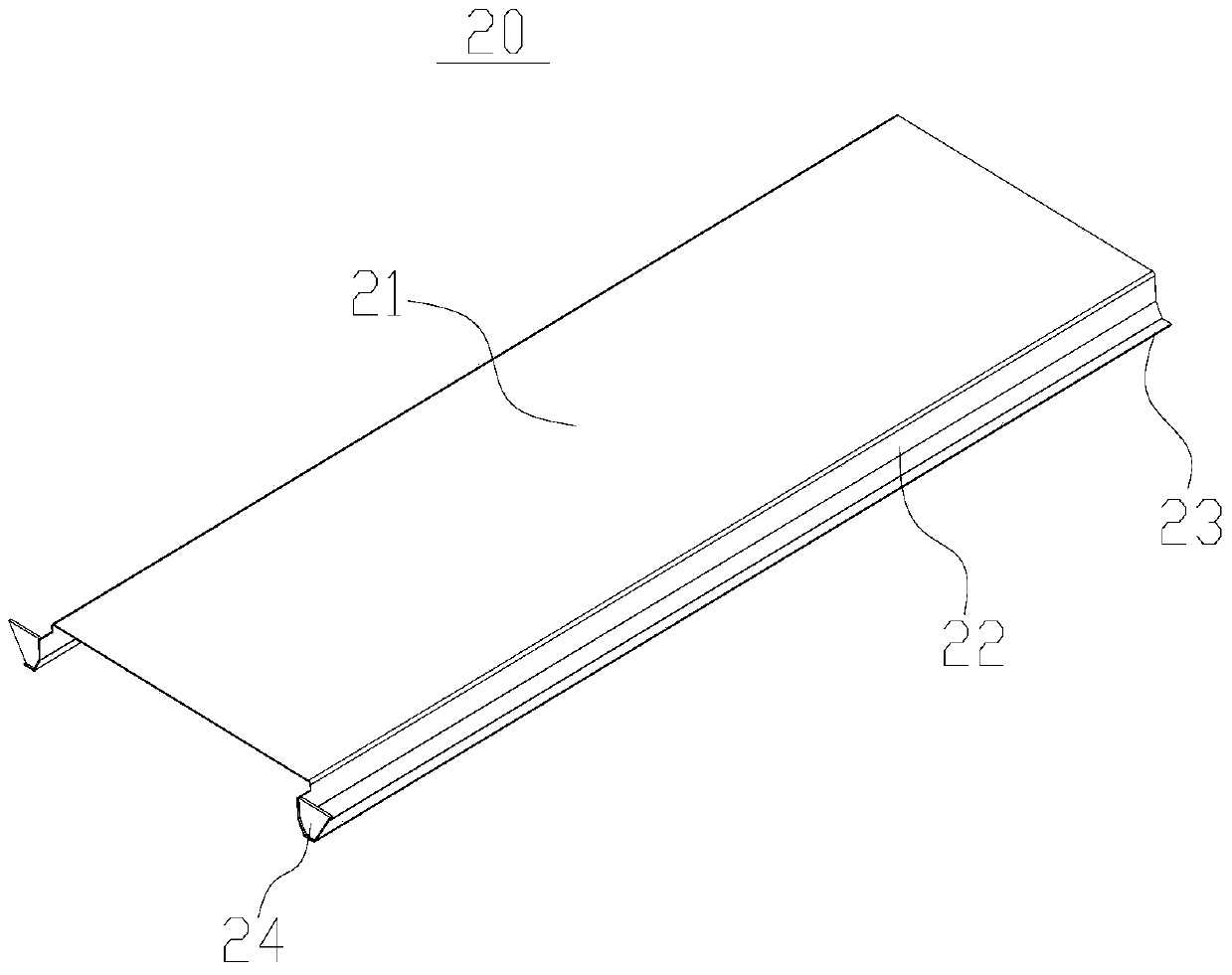

[0041] figure 2 The structure of the gooseneck groove according to the present invention is shown in one embodiment. image 3 shown figure 2 The structure of the side wall and wing plate of the gooseneck groove in the

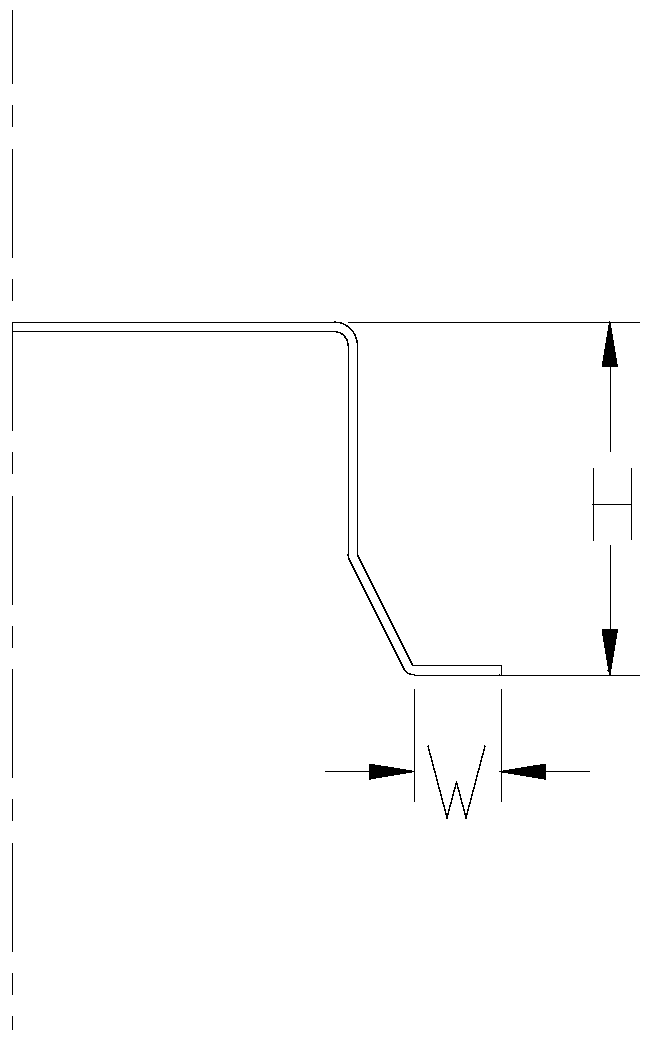

[0042] Such as figure 2 and image 3 As shown, in this embodiment, the gooseneck groove 20 includes: a top plate 21, a side wall 22, a wing plate 23 and a sealing plate 24, wherein the bent side wall 22 extends downward from both sides of the top plate 21 in the length direction, The wing plate 23 extends outward from the bent side wall 22; the sealing plate 24 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com