Dry and wet cycle ultraviolet light automatic corrosion test chamber and test method

A corrosion test, dry-wet cycle technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of difficult corrosion results and data collection, long corrosion test period, inability to accurately control, etc. The effect of experiment cost, manpower saving, and avoiding temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

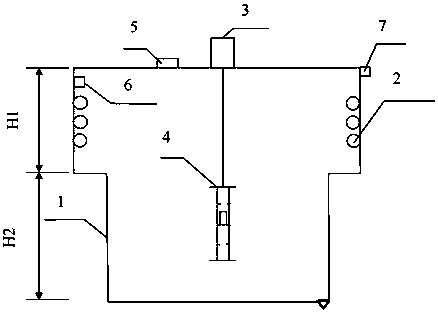

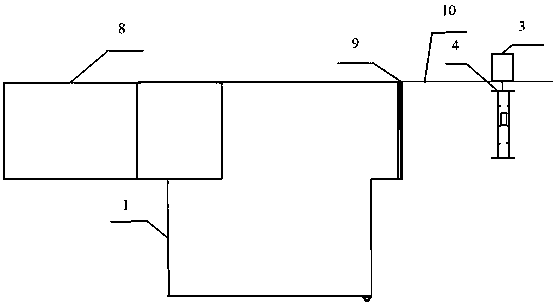

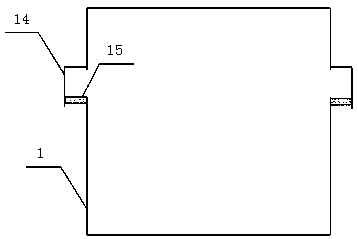

[0024] see Figure 1-3 , the outermost part of the dry-wet cycle ultraviolet light automatic corrosion test box of the present invention is a box body 1, and the box body 1 is square. The lower part of the box body 1 is a square solution soaking area, and the upper part is a square drying and ultraviolet light irradiation area. Corrosive solution is installed in the solution soaking area, the upper and lower height H2 of the solution soaking area is 500-800 mm, and the upper and lower height H1 of the ultraviolet irradiation area is 700-1000 mm. The left and right sides of the upper part of the structure protrude outward, and the protruding part is used as the area for drying and ultraviolet light source arrangement. The width of the upper part protruding outward is 150-200 mm in the left and right direction, so as to facilitate the arrangement of the high-pressure mercury lamp and lampshade of the ultraviolet light source.

[0025] A parallel ultraviolet light source system ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com