Method for treating waste water containing fluorine component

一种处理废水、废水的技术,应用在水/污水处理、自然水体处理、水处理参数控制等方向,能够解决成本高、不能减少氟排出量等问题,达到防止污染的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0021] The present invention will be described in more detail through the following preparation methods and examples. The preparation methods and examples described below are for better understanding of the present invention, and the present invention is not limited thereto.

[0022] 【Preparation method】Preparation of highly reactive polyisobutylene

[0023] The composite catalyst of isopropanol and boron trifluoride (by weight, isopropanol: boron trifluoride=1.45: 1) and the composition (C 4 - The reaction raw materials of residue-1) were continuously introduced into a stainless steel pressure reactor equipped with a cooling device, and the temperature was maintained at -23.0°C for the introduction of BF 3 . Relative to 100 parts by weight of isobutane, the BF 3 0.20 parts by weight. Keep the reactor pressure at 3kg / cm 2 Above, thereby make reaction raw material keep in liquid phase state, the residence time of reaction raw material is 30 minutes. After 180 minutes, the...

Embodiment 1~4, comparative Embodiment 1

[0026] [Examples 1 to 4, Comparative Examples 1 to 3] Treatment of Fluorine-Containing Component Wastewater

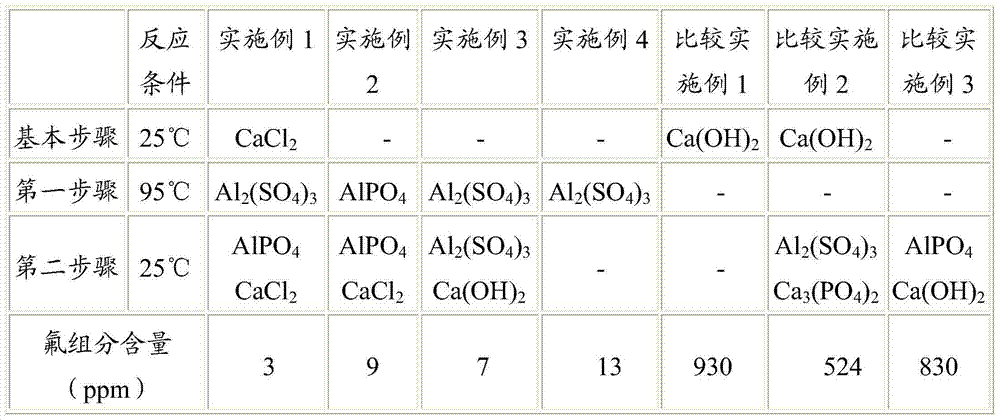

[0027] The temperature conditions and compounds shown in Table 2 below were used to treat the waste water with a fluorine content of 8530 ppm produced during the preparation of highly reactive polyisobutene to remove the fluorine contained in the waste water. The amount of the compound used in each step of wastewater treatment was about 1.2 equivalents relative to the fluorine concentration. The final fluorine component content in the wastewater treated with various reaction conditions and compounds was measured, and the results are shown in Table 2 below. In Table 2, "basic step" represents a fluoride removal step, "first step" represents a boron trifluoride salt removal step, and "second step" represents a residual fluorine component removal step.

[0028] Table 2

[0029]

[0030] As shown in Table 2, when only the general method of removing fluorine (calcium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com