Duckbilled seed metering device for peanut seeder and use method of duckbilled seed metering device

A technology of peanut seeder and seeding device, which is applied to the parts of the seeder, can solve the problems of time-consuming and labor-intensive, easy damage to the surface of the grain, uneven emergence, etc., and achieve the effect of small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

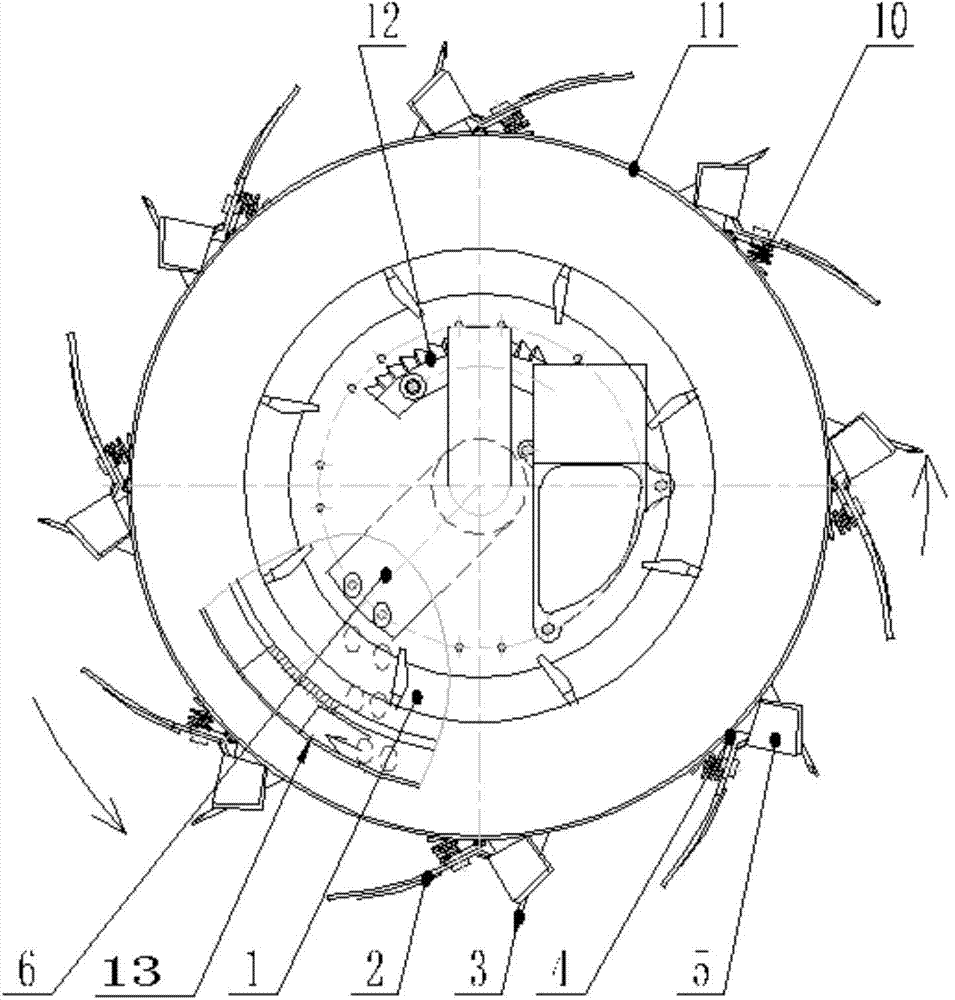

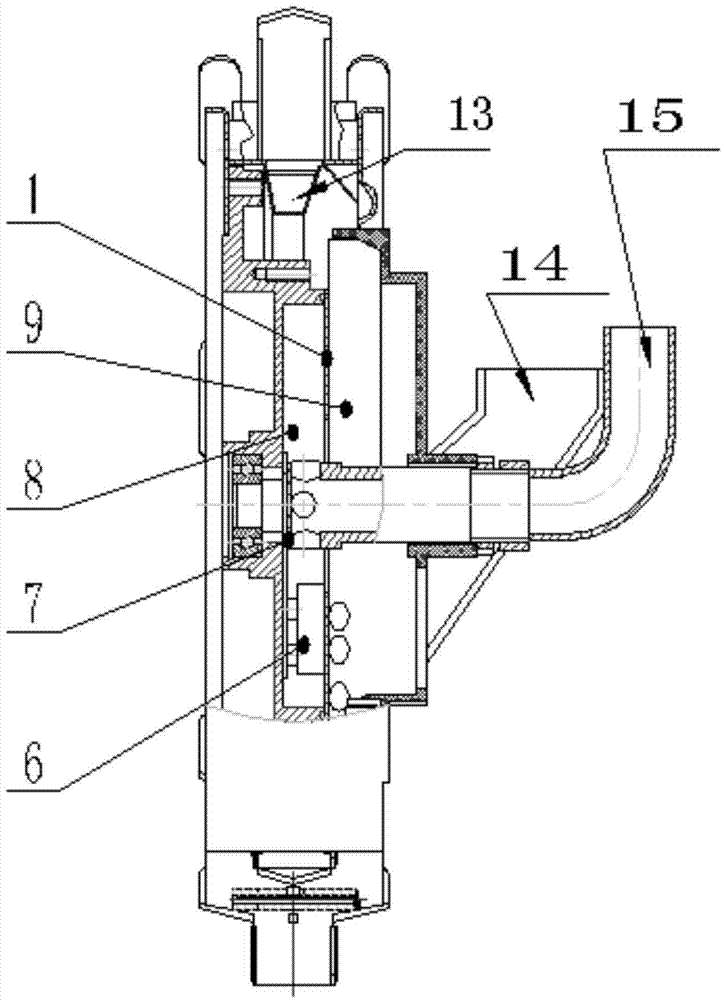

[0038] The specific implementation of a duckbill seeding device for a peanut planter of the present invention will be further described below in conjunction with the accompanying drawings.

[0039] In the first preferred embodiment of the present invention, a duckbill seeding device for a peanut planter is provided, comprising a seed tray 1, a pressure plate 2, a duckbill tube 3, a fixed pin 4, a movable valve mouth 5, and a blocking plate 6. Seed metering shaft 7, suction chamber 8, seed suction chamber 9, return spring 10, roller disc 11, seed scraper 12;

[0040] The inner side of the roller disc 11 is welded with a seed track 13 supporting the rotation of the seeds, and is set on the seed disc 1;

[0041] The seed disk 1 is rotatably and detachably set on the seed metering shaft 7;

[0042] The seed tray 1 completely separates the air suction chamber 8 connected to the air suction port 15 from the seed suction chamber 9 connected to the seed suction port 14;

[0043] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com