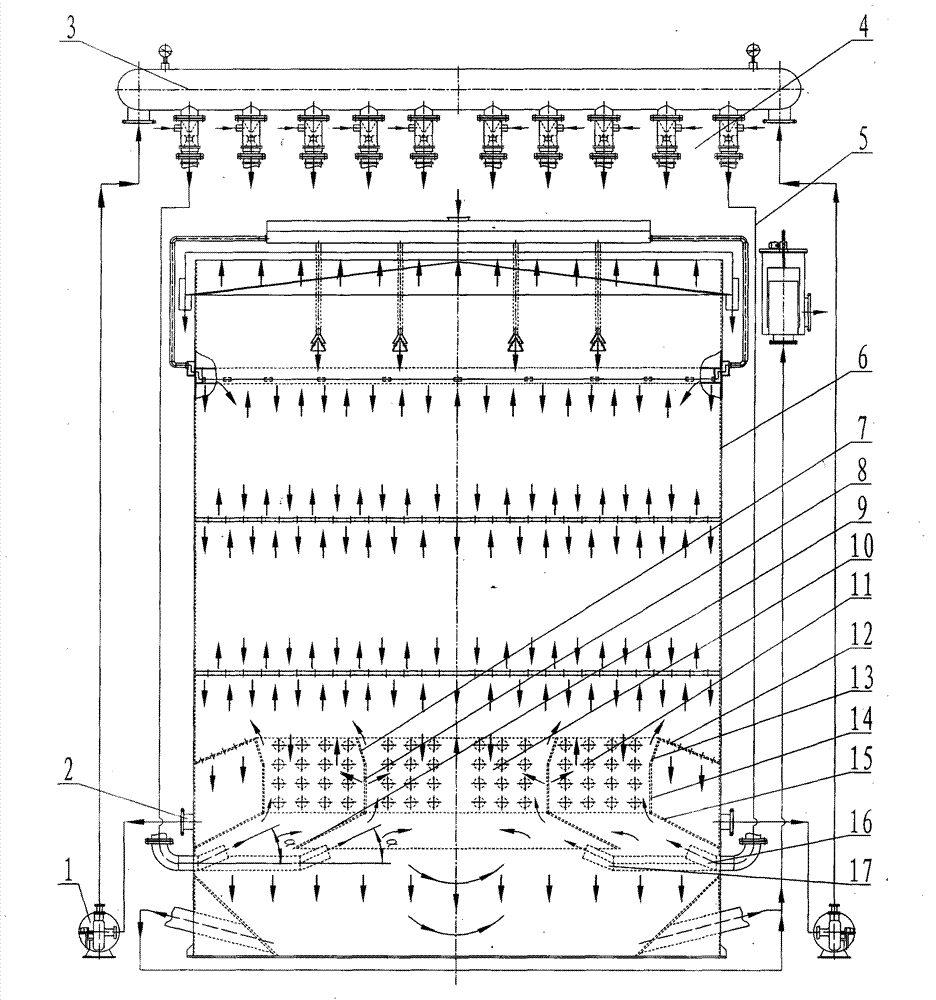

Large-sized floatation column middling dual-swirl device

A flotation column, double swirl technology, applied in flotation, solid separation and other directions, can solve the problems of poor countercurrent collision mineralization effect of medium ore pulp, uneven distribution of medium ore pulp, multiple equipments, etc., and achieve flotation concentrate. The liquid level is stable, the cyclone flotation effect is good, and the distribution is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

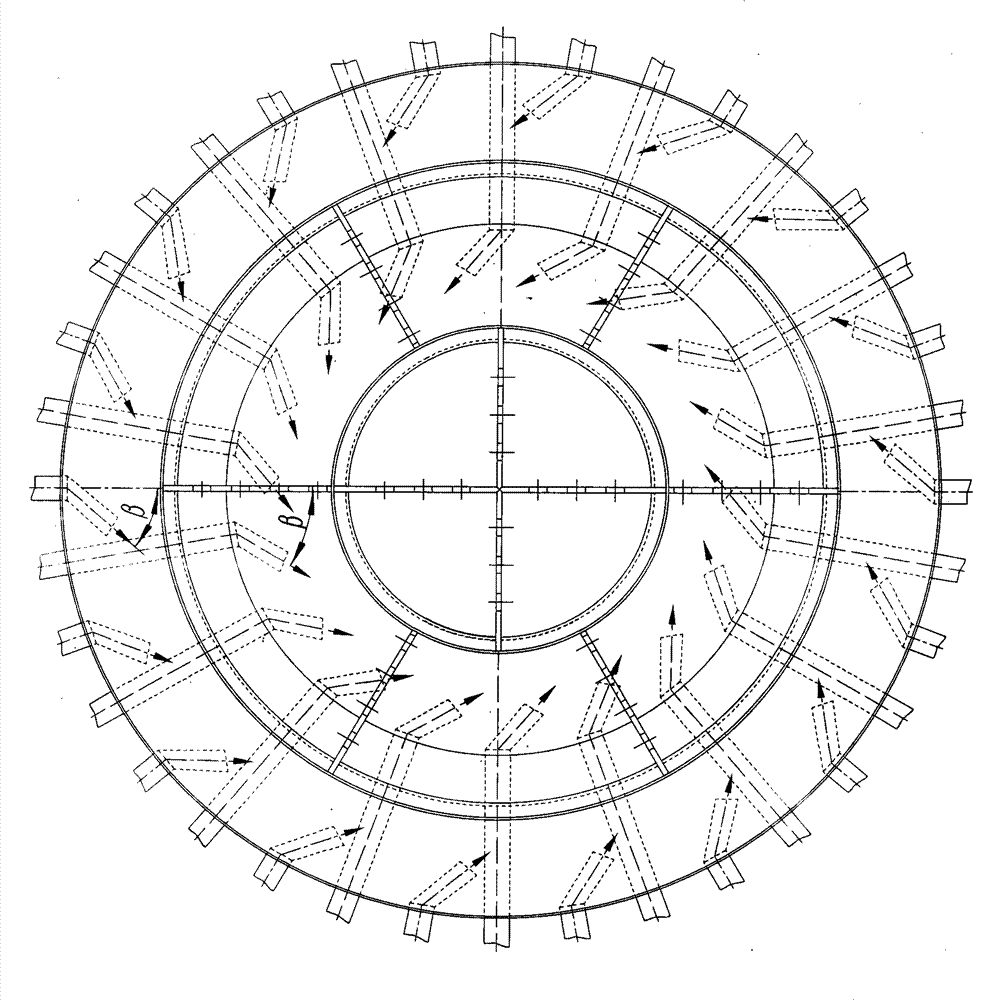

[0026]As shown in the figure: the middling slurry enters the middling circulating pump 1 through the middling discharge pipe 2 on both sides of the lower section of the flotation column body 6, and is transported by the middling circulating pump 1 to the distributor 3 for high-pressure mixing, then passes through the distributor The bottom discharge pipe of 3 enters the bubble generator 4, and then enters the medium ore feeding pipe (I) and the medium ore feeding pipe (II) respectively through the connecting pipe 5, and the medium ore slurry is respectively in the outer lower cone tube 15 and the inner lower cone Under the action of the inner side of the cylinder 9, a swirl force field is formed to realize swirl flotation; the upper end of the inner middle cone 8 is connected to the lower end of the inner upper cone 7, and the lower end of the inner middle cone 8 is connected to the inner lower cone 9 The upper end of the outer middle cone 14 is connected with the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com