A method and device for adjusting flow channel balance of one-mold multi-cavity mold

A multi-cavity and multi-cavity technology for one mold, applied in the field of adjusting the flow path balance of a multi-cavity mold, can solve the problems of reducing the service life of the mold, poor accuracy, mold deformation, etc., and achieve high accuracy and abstract problems The effect of embodiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

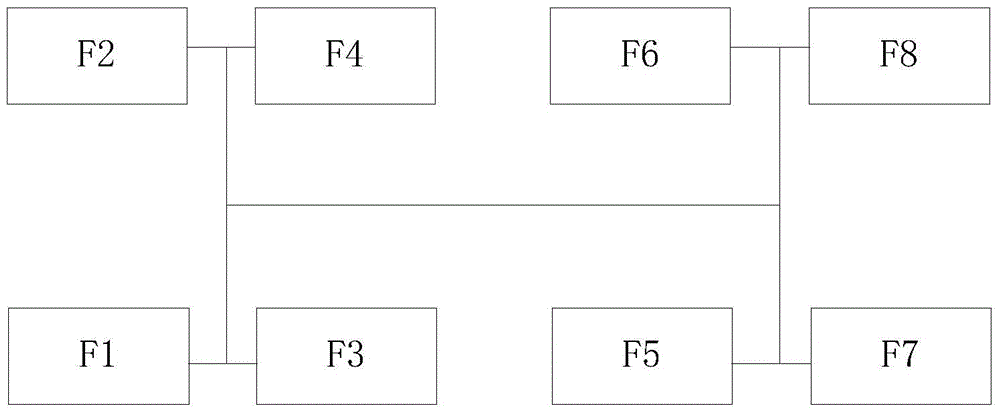

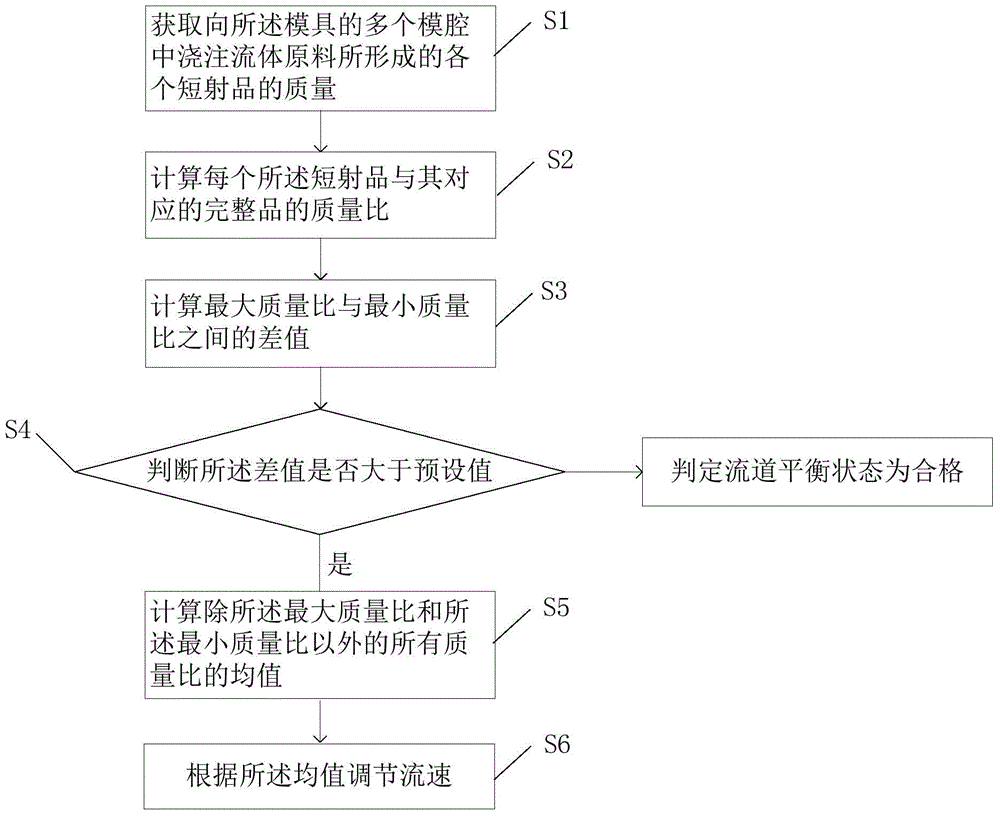

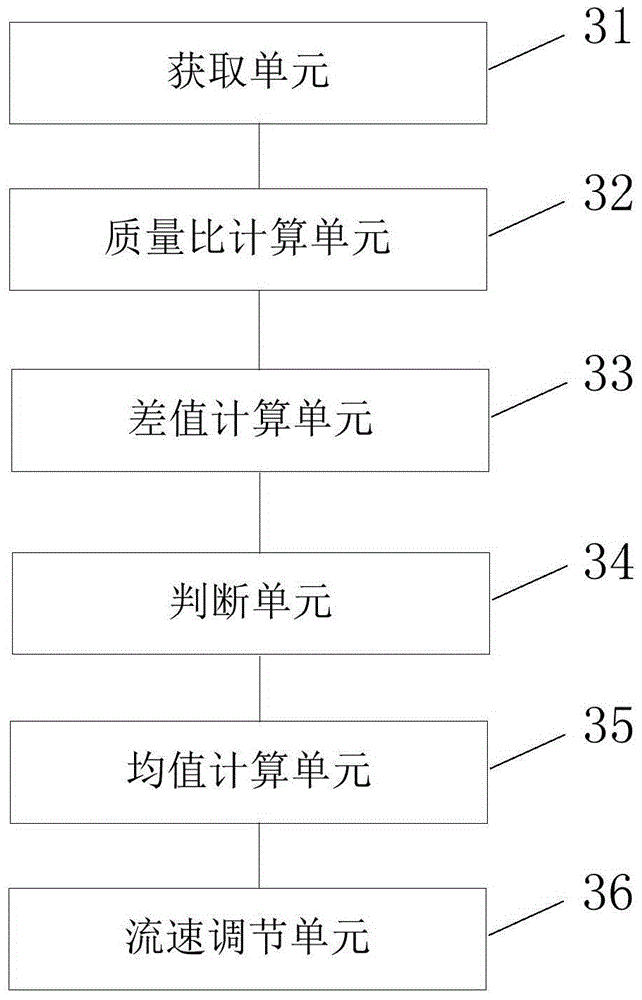

[0030] This embodiment provides a method for adjusting the runner balance of a multi-cavity mold. Before executing this method, first use the same parameters (including flow rate, throttle valve opening, etc.) figure 1 Inject the raw material into the 8 cavities of the mold shown to form 8 short shots, and then start to carry out the method, such as figure 2 As shown, this method includes:

[0031] S1. Obtain the quality of each short shot formed by pouring fluid raw materials into multiple cavities of the mold, that is, obtain the quality of the short shots manufactured by using the above mold cavities F1-F8, where the short shot refers to the material The product produced when the mold is not filled (0<fill rate<98%). In order to make the calculation results of the subsequent steps more accurate, the filling rate of the short shot is preferably 75%-95%.

[0032] S2. Calculate the mass ratio of each short-shot product to its corresponding complete product, wherein the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com