Cyclone Thermal Power Plant Coal Bunker Unclogging Equipment and Using Method

A technology for thermal power plants and coal bunker cleaning, applied in conveyor control devices, containers, packaging, etc., can solve problems such as jet air holes, solenoid valve damage, easy return, etc., to reduce friction coefficient and reduce friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

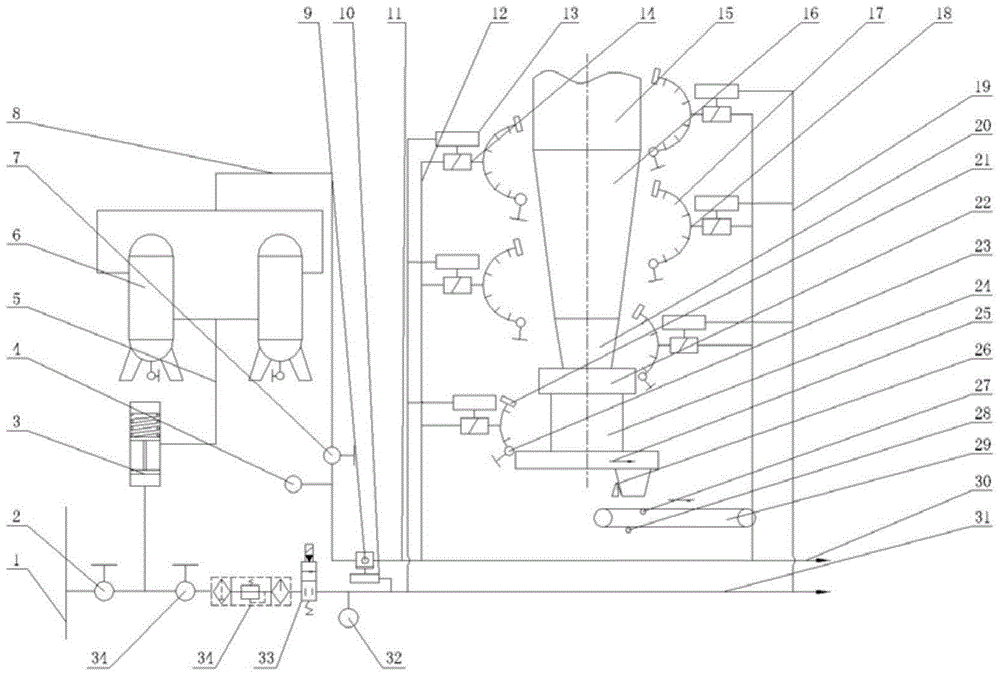

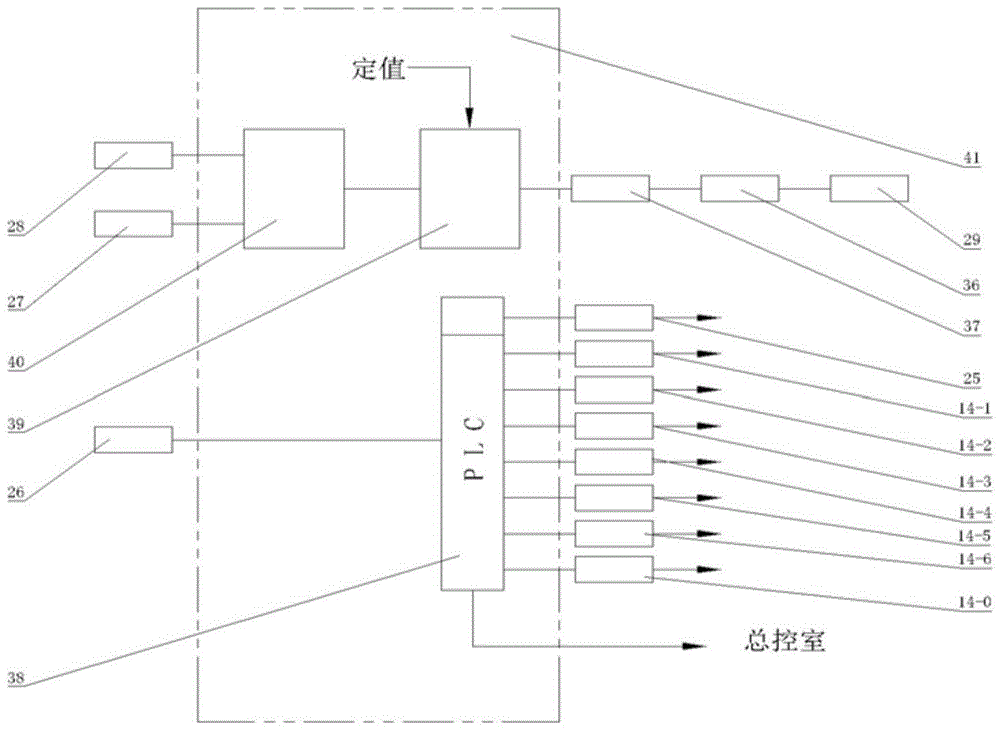

[0027] The coal bunker clearing equipment of the cyclone thermal power plant provided by the present invention includes a hyperbolic coal bunker, a gas supply pipeline network 1, a gas source system, a flow aid system, a flow aid control pipeline system, a signal acquisition system and a control system. The air supply pipe network 1 is the total working gas source as the coal bunker clearing equipment of the cyclone type thermal power plant of the present invention, and the compressed gas of the air supply pipe network 1 comes to the total compressed air station of the power plant, and its total air supply volume is 40m 3 / min, the pressure is not lower than 0.6MPa. The first manual ball valve 2 is the main air source valve of the flow aid system. After entering the system, it is divided into two paths, one path enters the minimum pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com