Anti-freezing control method and anti-freezing control device of cold and hot water unit, and cold and hot water unit

A technology for cold and hot water units and control devices, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as system damage, large impact, compressor damage, etc., to avoid freezing problems, avoid false protection, improve The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

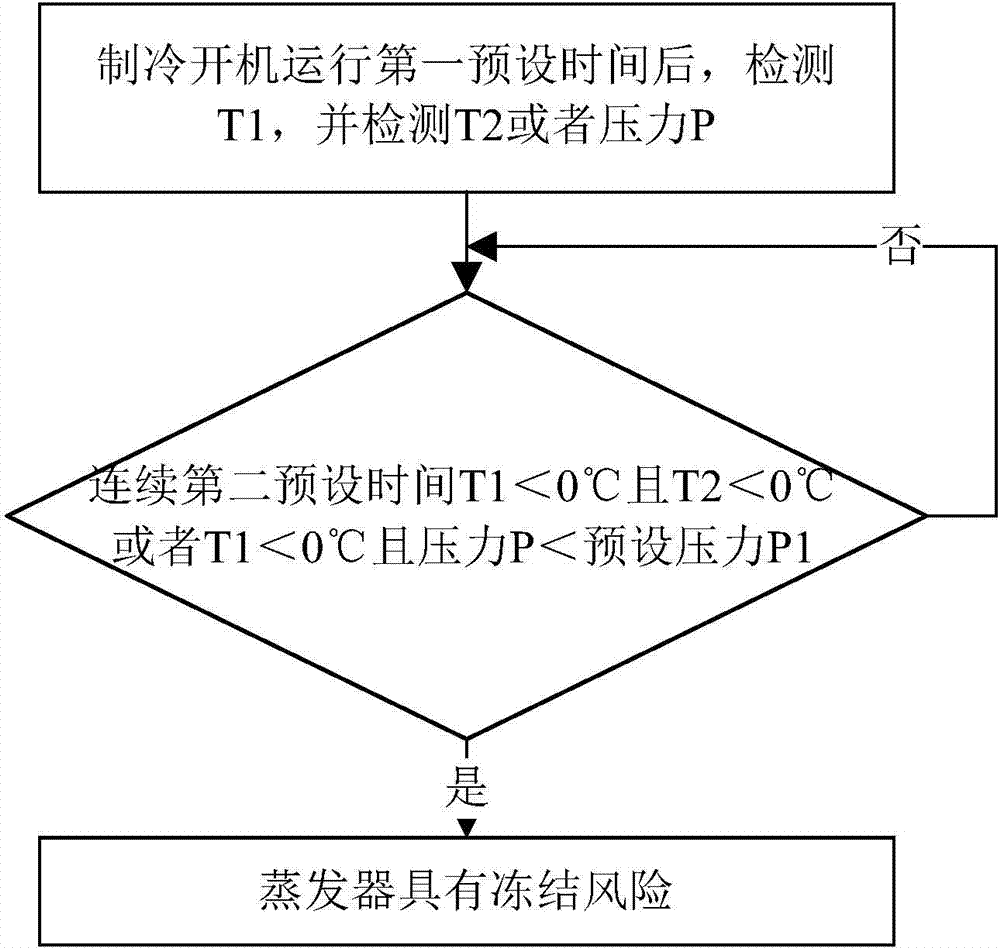

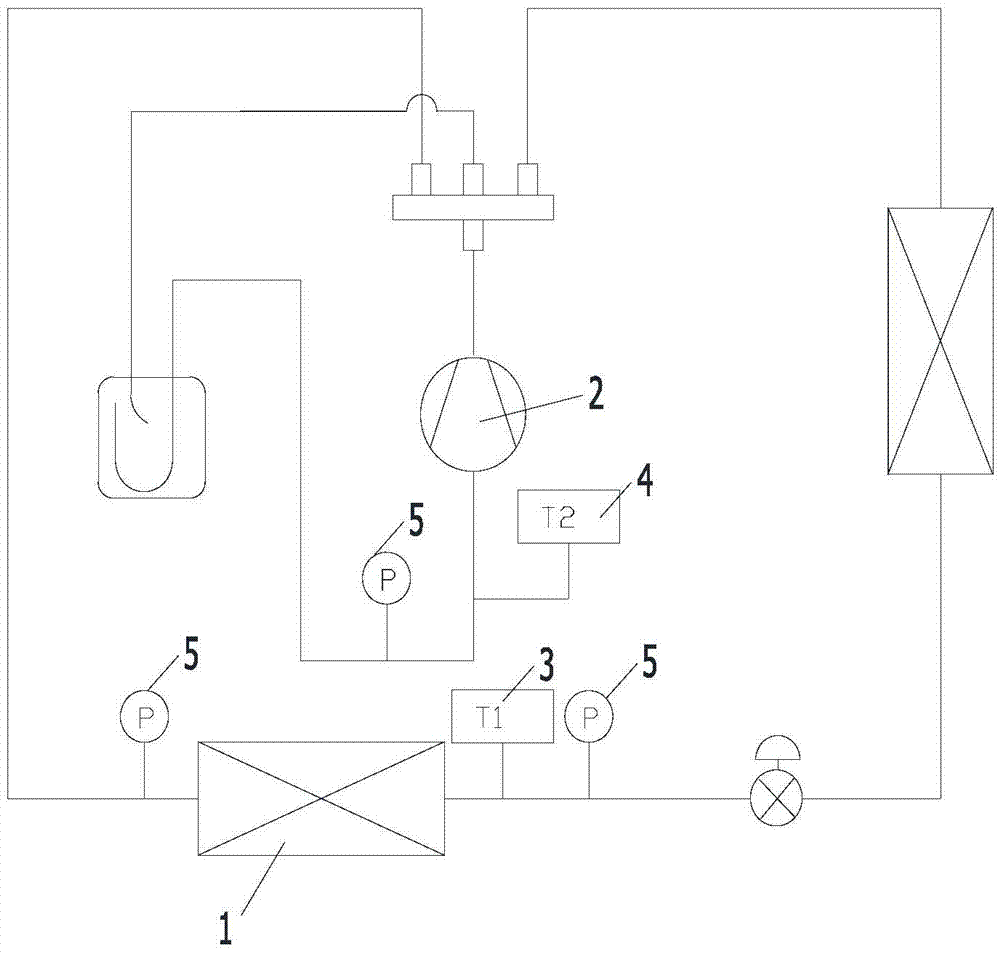

[0022] combine figure 1 and figure 2 Shown to illustrate the first embodiment of the freezing and hot water unit antifreezing control method of the present invention, in this embodiment, the antifreezing control method includes: detecting the refrigerant inlet temperature T1 of the evaporator; detecting the compressor suction temperature T2; detecting the compression The pressure P at any one of the three places: the suction port of the machine, the refrigerant inlet of the evaporator, and the refrigerant outlet of the evaporator; after the refrigeration is started for the first preset time, if T1<0°C for the second consecutive preset time , and T2<0°C or pressure P<preset pressure P1, it is determined that the evaporator has a risk of freezing. The invention detects the refrigerant inlet temperature of the evaporator, the compressor suction temperature and the refrigerant pressure P, and jointly judges whether the evaporator has a risk of freezing, thereby avoiding the free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com