Method of mooring of ship and arrangement to accomplish the method

A technology for boats and mooring, which is used in boat construction, boat parts, special purpose boats, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

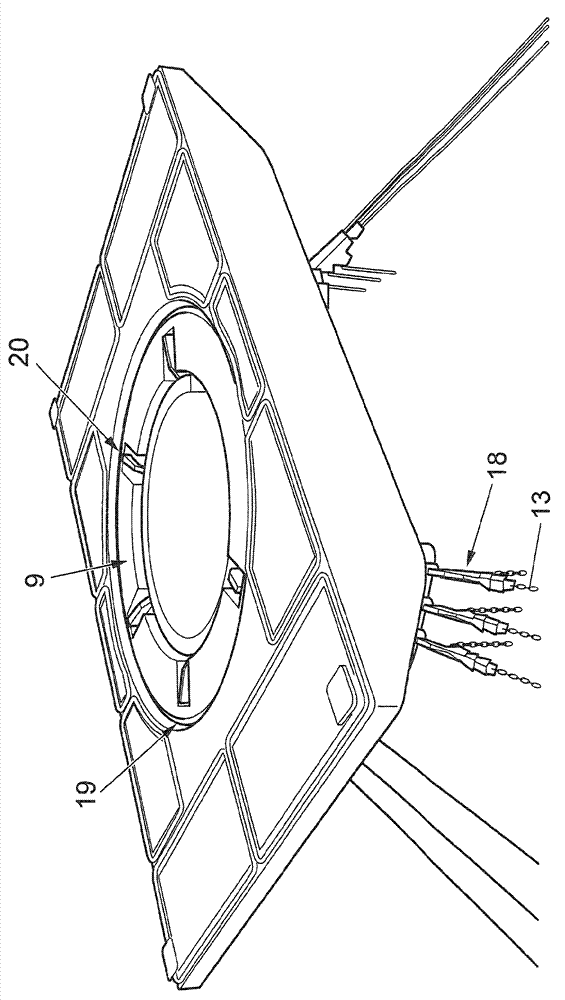

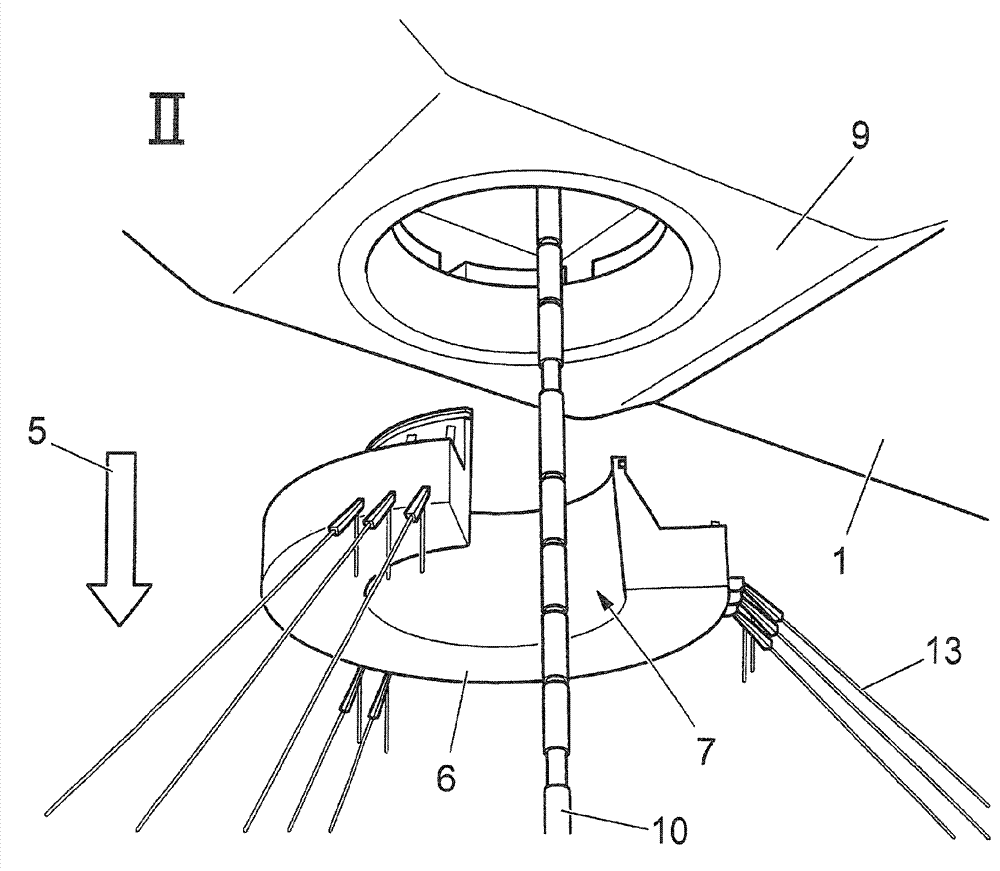

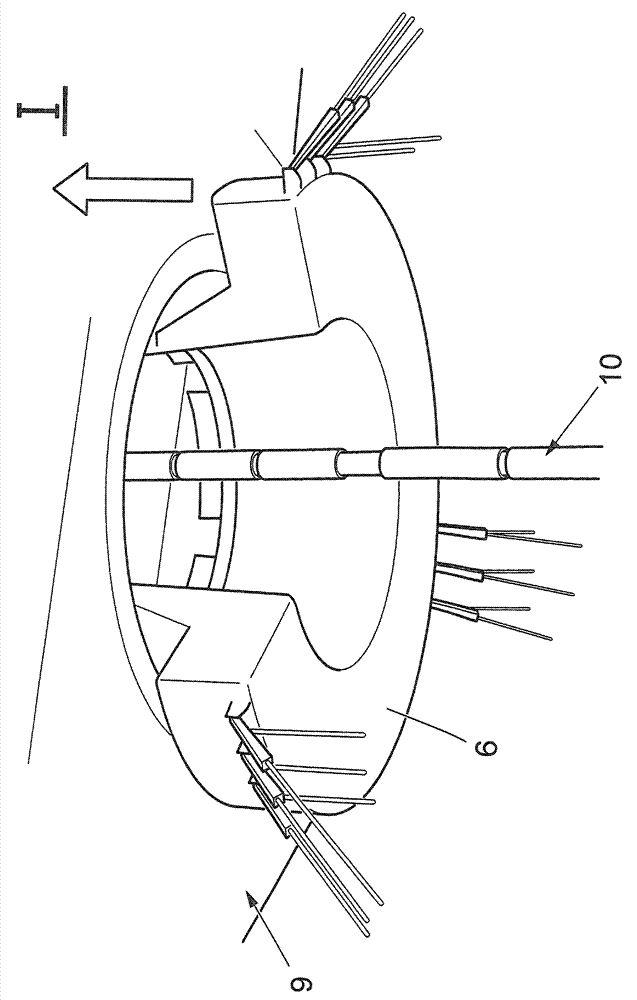

[0018] A method that enables safe mooring of a vessel 1 in a defined position at a certain distance from the land 2 and makes it possible to leave the berth 3 of the vessel concerned means that mooring is achieved with a mooring unit 6 which can be raised 4 and lowered 5 and it has a gap 7 seen along its circumference. Furthermore, said mooring unit 6 is configured such that by means of a connectable part 9 located below the water surface 8, it can be connected I to and disconnected II from the vessel 1, respectively. Said mooring unit 6 makes it possible to pass the vessel 1, and the downwardly protruding load 10 supported by the vessel, after disconnecting and lowering the mooring unit 6, and said unit can rotate substantially vertically with respect to the vessel 1. The straight imaginary axis 11 rotates.

[0019] According to the invention, said mooring unit 6 is remotely controlled in order to achieve the desired raising 4 and lowering 5 thereof, and is moored by means o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com