A paste concentrator for a steel structure pool

A kind of steel structure, technology of thickening machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

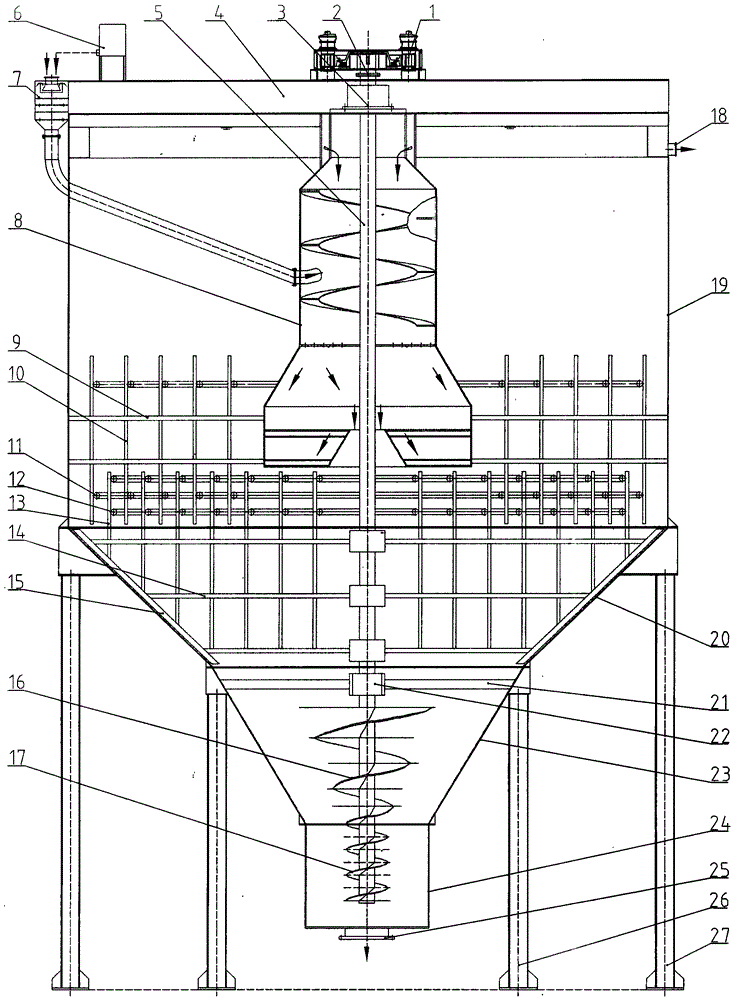

[0024] The flocculant and pulp prepared by the flocculant dosing device 6 flow into the static mixer 7, and then flow to the middle of the central mixing well 8, and the large flocs will continue to sink into the compression settling zone; the hydraulic motor drive device 1 passes through the joint The shaft device 2 is connected with the transmission shaft 5, and the transmission shaft 5 drives the rotating horizontal rod 14, the rotating vertical rod 13, the rotating reinforcing ring 12, the mud scraper 15, the conical spiral blade 16, and the lower spiral blade 17 to rotate, extruding the flocs, In addition, the rotating vertical rod 13 and the fixed vertical rod 10 are installed alternately to squeeze the flocs together, which can also help release the water in the flocs and increase the tailings discharge concentration of the thickener; finally, the tailings slurry is discharged through the bottom of the lower drum 24 The pipe 25 is discharged in time, and the overflow wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com