Device for detecting abnormity of deionized water cleaning valve in semiconductor process technology

A technology for deionized water and cleaning valves, which is applied in the direction of measuring devices, grinding devices, manufacturing tools, etc., and can solve the problems of inability to detect damage and blockage of deionized water cleaning valves in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

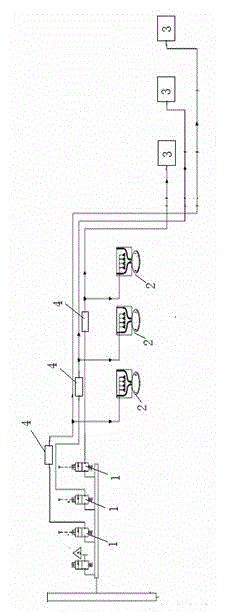

[0012] Such as figure 1 As shown, a device for detecting the abnormality of the deionized water cleaning valve in the semiconductor manufacturing process is installed in three deionized water cleaning control units, and each of the deionized water cleaning control units includes a cleaning valve 1, respectively The liner high-pressure flushing unit 2 and the liner adjustment cleaning unit 3 connected to the cleaning valve 1 through pipelines, the device includes: three flow monitoring components 4, which are respectively arranged between the cleaning valve 1 and the liner high-pressure flushing unit 2 Monitor the flow rate of deionized water on the pipe between. The flow monitoring component 4 is a flow meter.

[0013] When the semiconductor chemical mechanical polishing equipment (CMP) is flattening or polishi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com