Medical oxygen production host PLC intelligent integrated control system

A host, intelligent technology, applied in the general control system, control/regulation system, program control in the sequence/logic controller, etc., can solve the problems of detection, no other equipment start-stop control and operation, and achieve easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

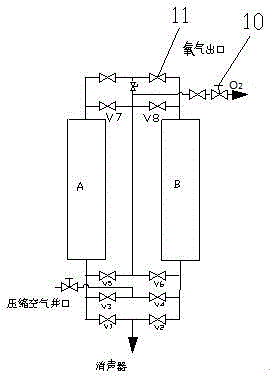

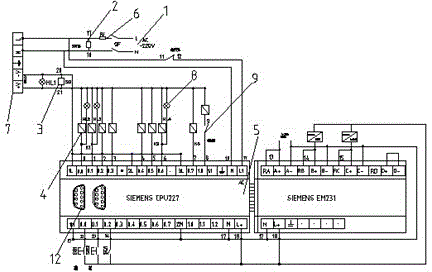

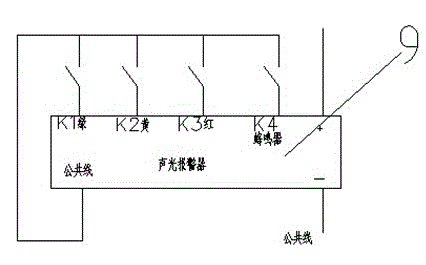

[0027] refer to Figure 1-Figure 3 Shown: a PLC intelligent joint control system for a medical oxygen generator host, including a power supply 1, an oxygen analyzer 2, a touch screen 3, a relay 4, an indicator light 8 and a program controller 5, and a fuse 6 is provided at one end of the power supply 1, The fuse 6 is connected to the oxygen analyzer 2, and a rectifier transformer 7 is arranged on one side of the oxygen analyzer 2, and the indicator light 8 includes an indicator light 1, an indicator light 2, an indicator light 3 and an indicator light 4. The rectifier transformer 7 is provided with an indicator light 1. When in use, the program controller 5 can control the solenoid valve 10 and the pneumatic valve 11 according to the compiled program. When an unexpected situation occurs, the program can also be temporarily manually controlled. Described indicator lamp one is connected with touch screen 3, and described program controller 5 is provided with indicator lamp two, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com