Device and method for distributing extrusion materials of plastic pipe

A plastic pipe and feeding device technology, applied in the field of plastic extrusion, can solve the problems of poor practicability, low degree of automation, complex structure, etc., and achieve the effects of simple structure, labor saving, and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

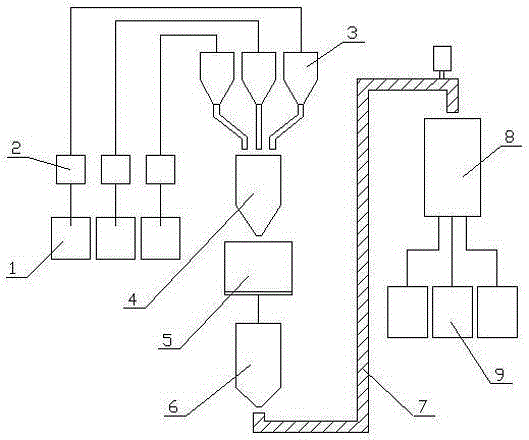

[0019] Plastic pipe extruded material dispensing device of the present invention, as figure 1 As shown, it includes several raw material boxes 1 for storing different extrusion raw materials, and each raw material box 1 is respectively connected to an automatic metering and blanking device 3 through a feeding device 2, so as to transport the extrusion raw materials in each raw material box 1 to In the corresponding automatic metering and blanking equipment 3, each automatic metering and blanking equipment 3 is connected to the feed port of the same mixing hopper 4, and the discharge port of the mixing hopper 4 is connected to the stirring device to stir the mixed raw materials evenly, The stirring device is connected to the feed bin 8 through the transmission mechanism 7, and the feed bin 8 is connected to each extruder 9 through conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com