Electric car wheel edge driving device

A technology for electric vehicle wheels and driving devices, which is applied in the direction of power devices, control devices, motion deposition, etc., can solve the problems of increasing the offset distance from the steering knuckle to the hub bearing, shortening the service life of the hub bearing, and the motor cannot be placed on the wheel, etc., to achieve Effects of avoiding interference, improving motor efficiency, and easy design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

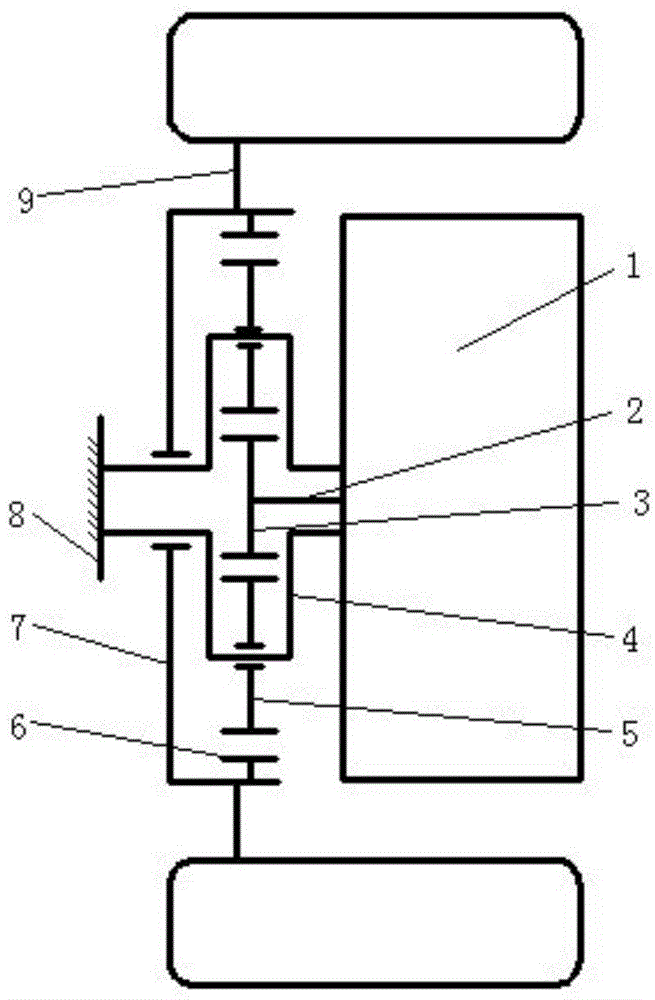

[0026] In this example, if figure 1 As shown, a wheel drive device for an electric vehicle includes a motor 1 and a wheel speed reduction device; in a specific implementation, the motor 1 is a permanent magnet brushless DC motor; and the wheel speed reduction device includes: a sun gear 3, a planetary gear 5, an inner ring gear 6 and planet carrier 4;

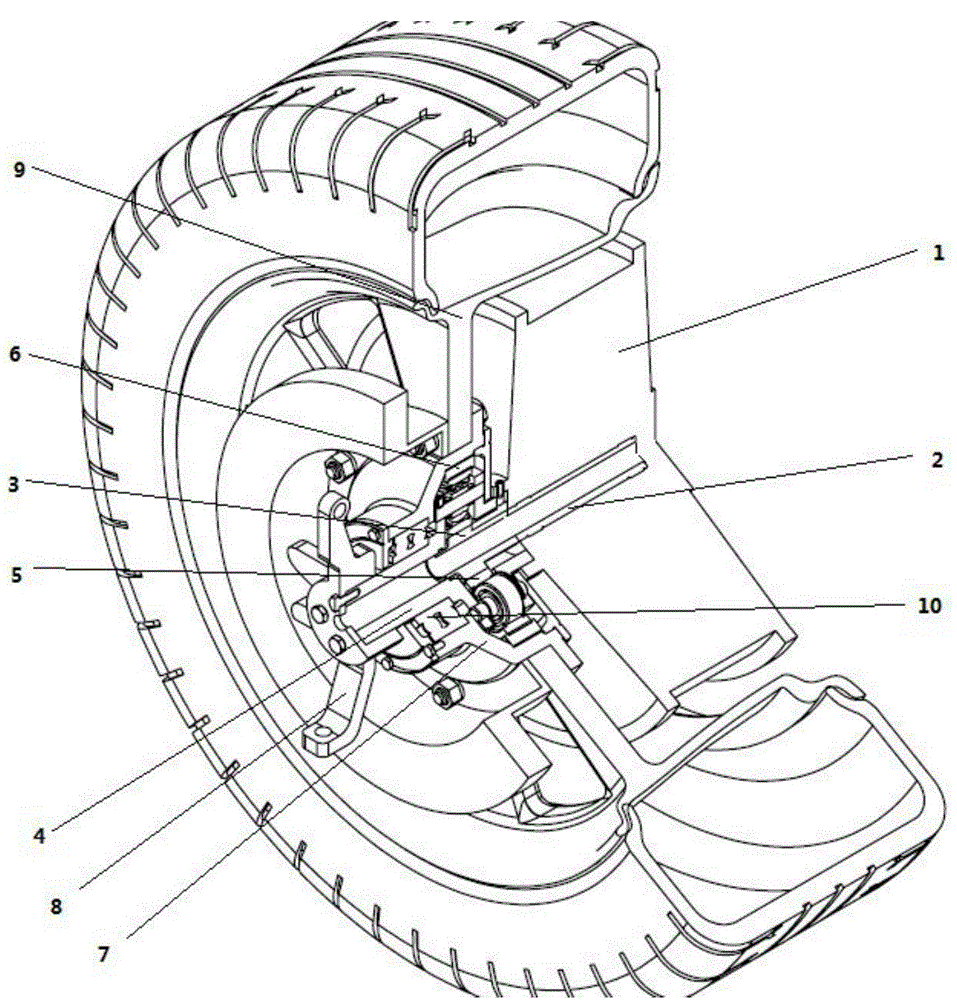

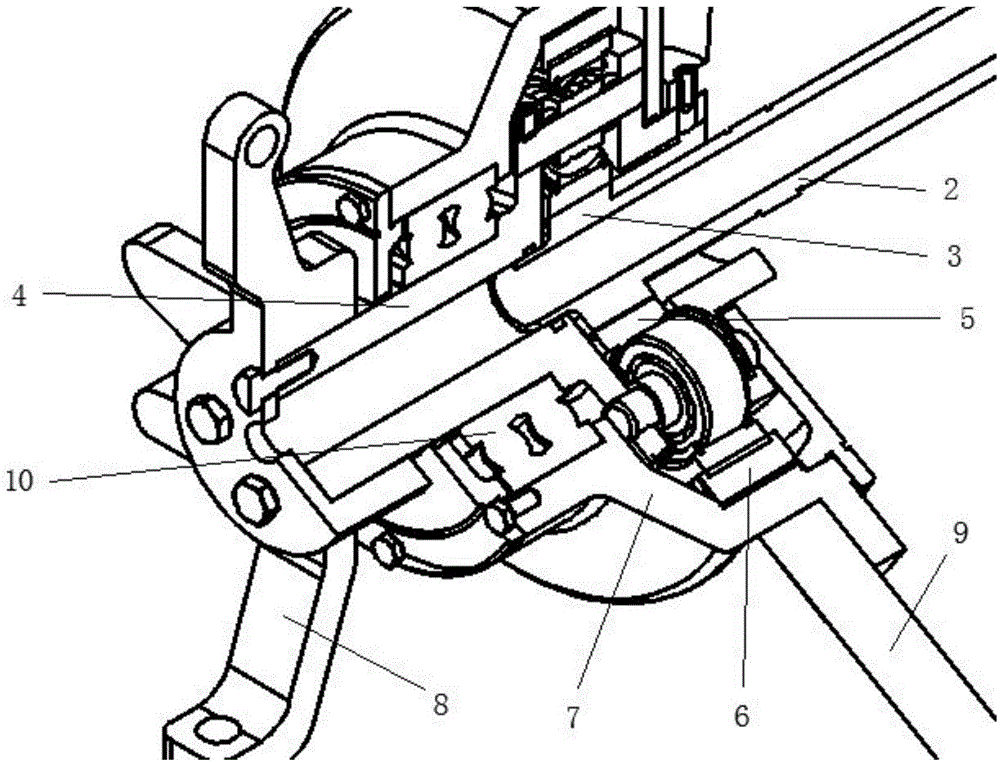

[0027] see figure 2 with image 3 , the spokes of the electric vehicle hub 9 are arranged on the inner side of the wheel hub 4, and the motor 2 is arranged inside the electric vehicle wheel hub 9, on the outer side of the spokes, and is fixedly connected to one end of the planetary carrier 4, so that the wheel drive device can be shortened The axial dimension reduces the offset distance from the steering knuckle 8 to the hub bearing 10, prolongs the service life of the hub bearing 10, and effectively avoids the interference of the wheel drive device with the suspension and shock absorber, making the design of the steering sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com