Large round billet loading reinforcement bracket

A large round steel billet and reinforcement bracket technology, which is applied in transportation and packaging, cargo support/fastening parts, railway car body parts, etc., can solve the problems of lateral movement and longitudinal movement of large round steel billets, so as to ensure close contact and effective friction , to achieve the effect of railway safety transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

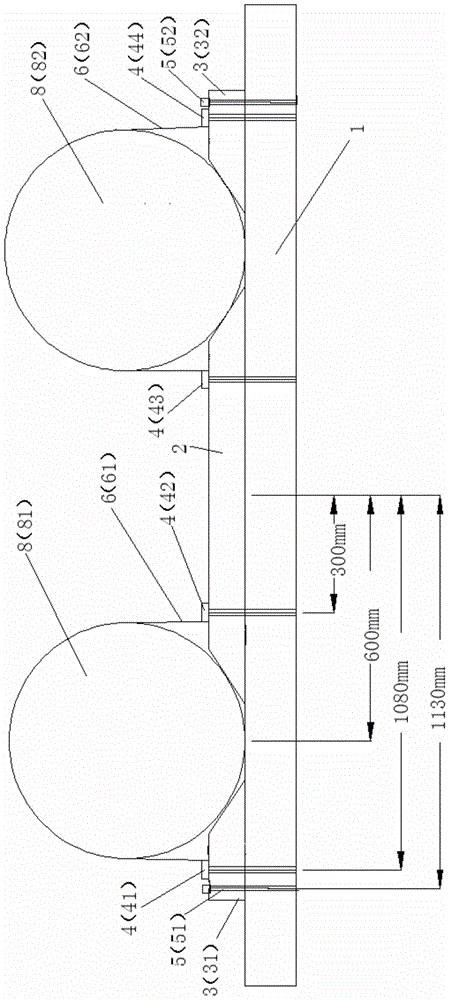

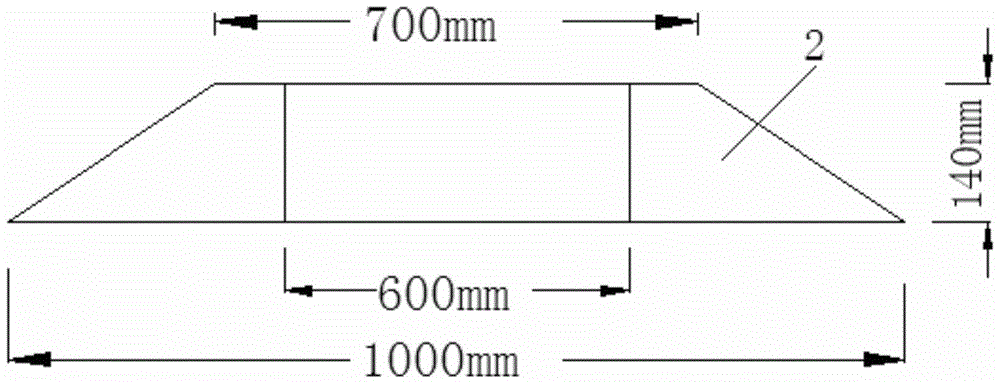

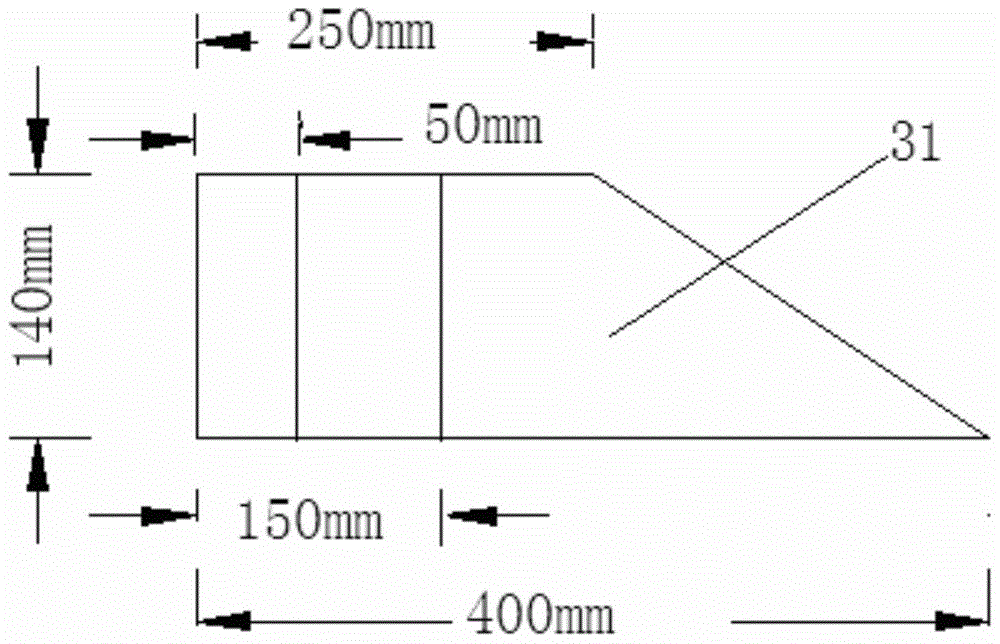

[0027] Such as figure 1 , figure 2 with image 3 As shown, the large round steel billet 8 loading reinforcement bracket in the preferred embodiment of the present invention mainly includes a horizontal skid 1, which is used to provide installation support; a middle cover 2, which is fixedly installed in the middle of the upper end surface of the horizontal skid 1; a left end cover 31 , fixedly installed at the left end position of the upper end face of the cross skid 1, the first installation space is formed between the right end of the left end mask 31 and the left end of the middle mask 2, for placing the first large round steel billet 81; the right end mask 32, It is fixedly installed at the right end of the upper end surface of the cross skid 1, and forms a second installation space between the left end of the right end mask 32...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com