Burglary-resistant lock based on spiral type reverse clutch module and double-motor module

A screw-type, dual-motor technology, applied in the field of tamper-resistant locks, can solve problems such as easy-to-open door locks, motor jamming and burning, and troublesome lock body installation, achieving high safety, reducing the risk of stopping work, and increasing safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

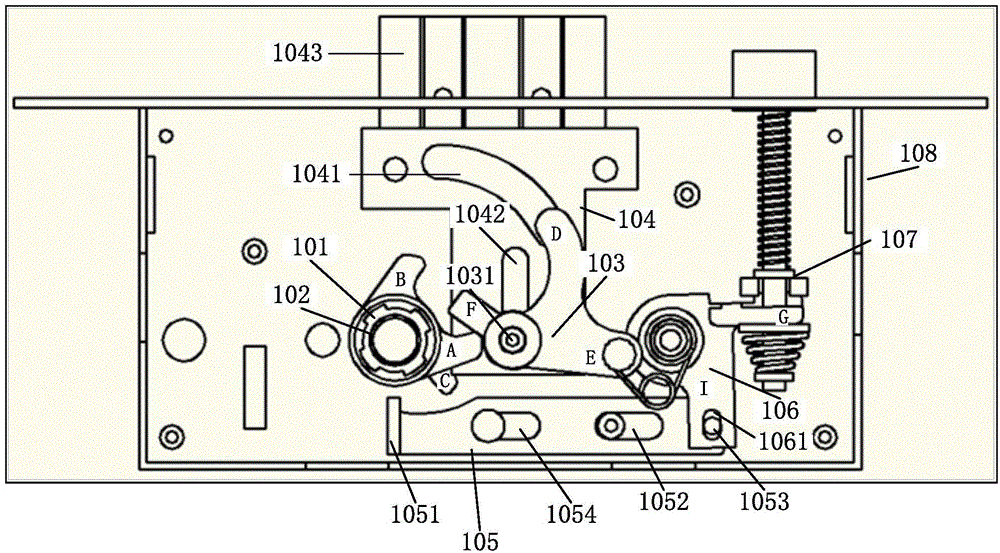

[0032] The tamper-resistant lock based on the screw-type back-clutch module and the double-motor module of the present invention includes: a lock body module, a screw-type back-clutch module and a double-motor module; wherein,

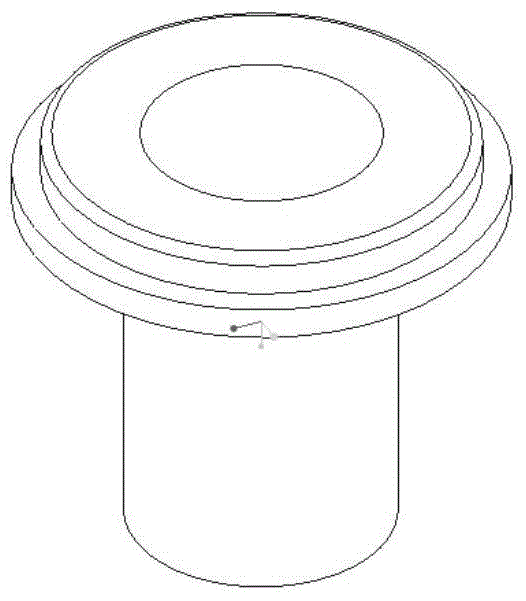

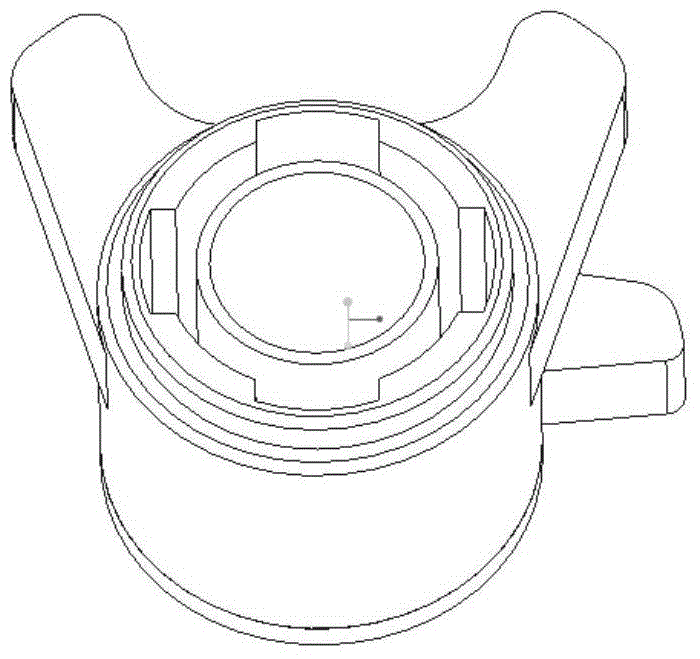

[0033] like figure 1As shown, the lock body module of the present invention includes: a main bolt shifting block 101, an anti-pry sleeve 102, a main bolt shifting rod 103, a main dead bolt assembly 104, an oblique bolt connecting rod assembly 105, and an oblique bolt shifting rod 106 , oblique bolt assembly 107, lock body box 108, cylindrical shaft and torsion spring. like figure 2 As shown, the main bolt shifting block 101 is provided with a first extension arm A, a second extension arm B, and a third extension arm C; and the axial center position of the main bolt shifting block 101 is provided with a sleeve through hole , and the inner peripheral surface is provided with an axial slot matching with the transmission assembly; one end of the tamper-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com