A Solid Micro Thruster Array Structure for Test

A technology of micro-thrust and array structure, which is applied in jet propulsion devices, machines/engines, rocket engine devices, etc., can solve the problems that there is no thruster array performance test and ignition test, which is not conducive to the realization of scale expansion and large-scale problems. Test and other problems, to achieve the effect of reducing development cycle and cost, high ignition success rate and low ignition power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

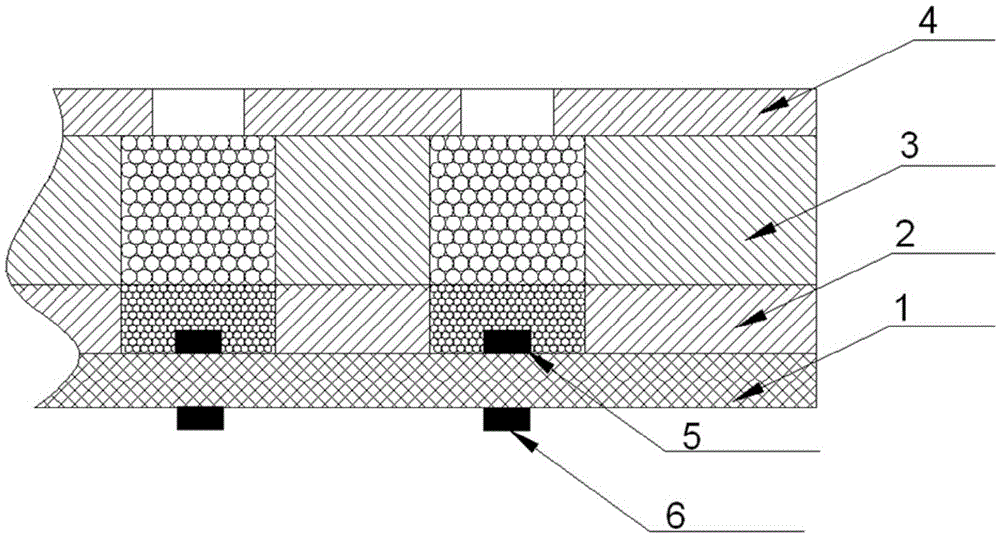

[0025] The solid micro thruster structure of the present invention mainly includes an ignition circuit layer, an ignition powder layer, a combustion chamber layer and a nozzle layer. Thruster array size is 10×10 (10 columns, 10 rows), 100×100 (100 columns, 100 rows).

[0026] 1 Solid Micro Thruster Array Structure

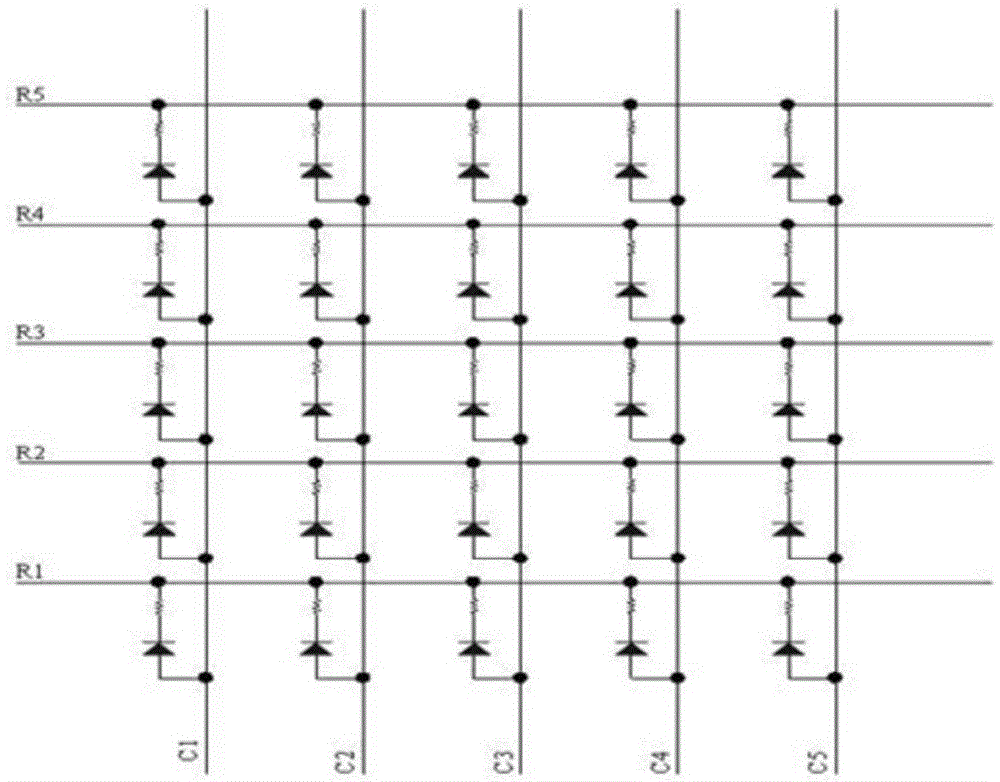

[0027] (1) Micro thruster array ignition circuit

[0028] The ignition circuit consists of a two-layer design, the upper layer is a resistor, and the lower layer is a diode, which are connected through row lines and column lines. One end of each heating resistor is connected to the anode of a diode, and the other end of the heating resistor is connected to the row line. The cathode of the diode The connection is on the column line; the row line and the column line are respectively distributed in different integrated circuit boards and do not affect each other. In order to distinguish it from the independent ignition circuit, this kind of ignition circuit is calle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com