Electric junction box

An electrical junction box and frame technology, applied to electrical components and other directions, can solve the problems of poor assembly workability, difficulty in accurate positioning of multiple locked parts 5, etc., and achieve the effects of easy assembly, simplified structure, and improved rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

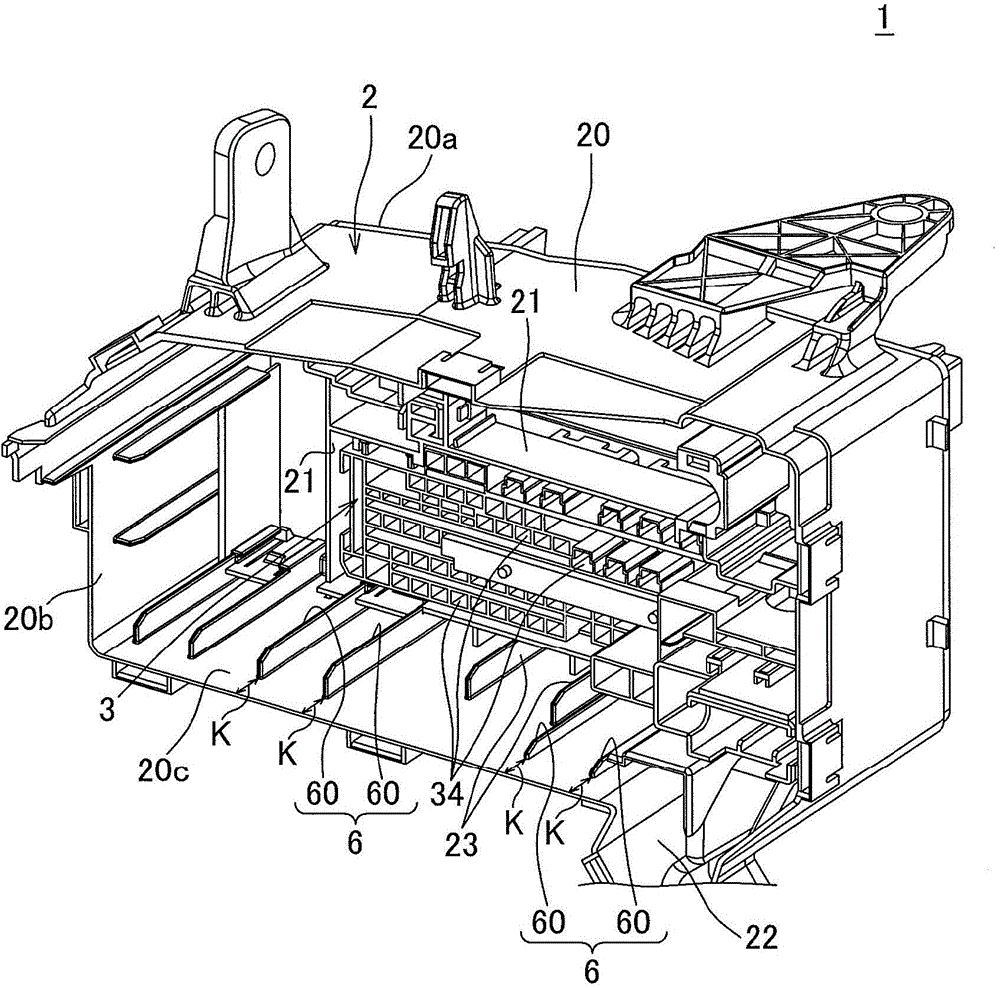

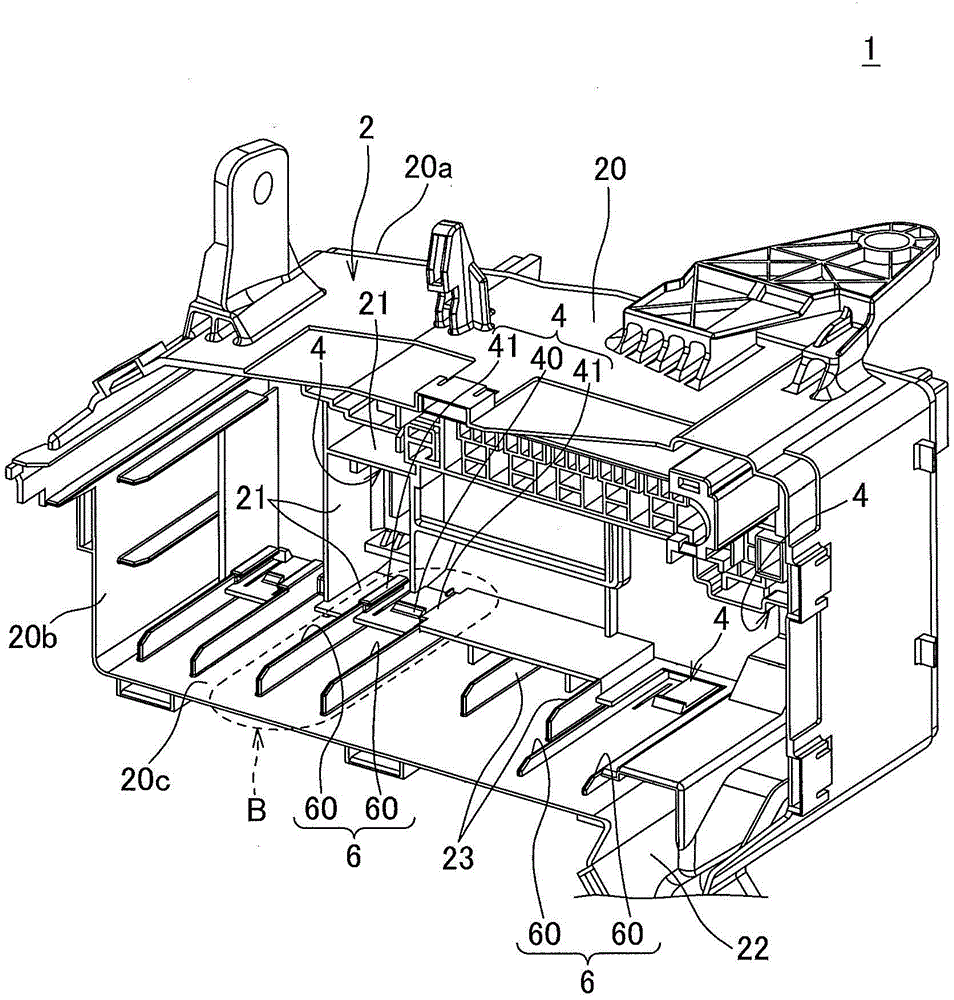

[0036] refer to Figure 1~6 An "electric junction box" according to one embodiment of the present invention will be described. figure 1 The illustrated electrical junction box 1 is mounted on an automobile and mainly performs power distribution. This electrical junction box 1 includes: a frame 2 made of synthetic resin having a frame-shaped peripheral wall 20 ; and a plurality of modules made of synthetic resin assembled inside the frame 2 . In addition, in this specification, one module 3 is demonstrated on behalf of a plurality of modules.

[0037] The framework 2 as figure 2 As shown, there is a peripheral wall 20 ; and a plurality of inner walls 21 dividing the inner space of the peripheral wall 20 . The peripheral wall 20 is formed in a cylindrical shape as described above, and has openings 20a, 20b.

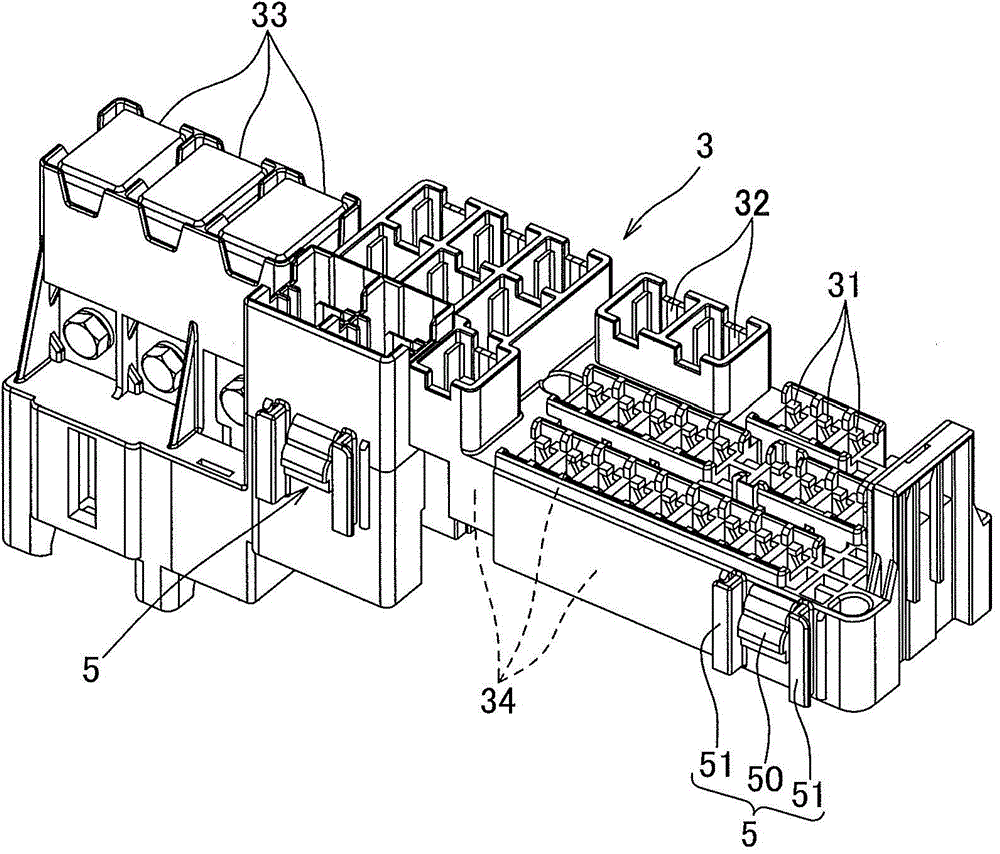

[0038] The above module 3 as image 3 As shown, a wire insertion portion 34 is provided on one side, and electronic component mounting portions 31 , 32 , and 33 for ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap