Sealing system

A technology for sealing components and orifices, which is used in the system and wiring of pipes and pipes, and can solve problems such as damage to electronic components and electric shocks for staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

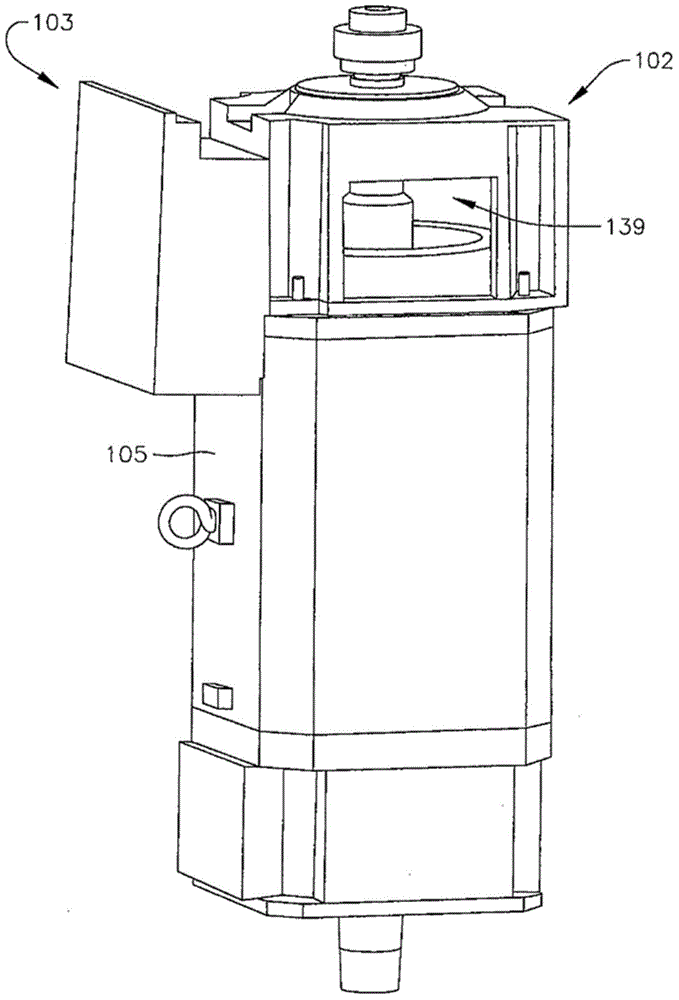

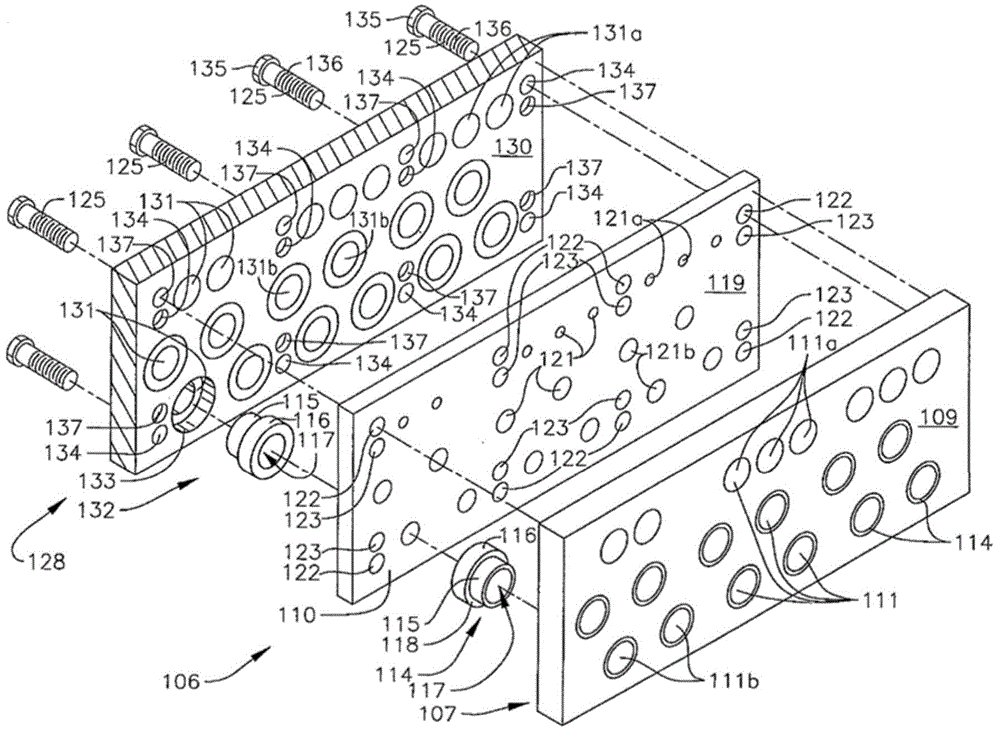

[0015] The present invention relates to a system for creating a watertight seal around one or more flexible longitudinal members extending through a panel section. refer to figure 1 In the illustrated embodiment, sealing system 100 is configured to create a watertight seal around a plurality of various wires, cables, conduits, pipes, hoses and / or conduits 101 (also referred to herein as "flexible longitudinal members"), as described above. A flexible longitudinal member extends from the top drive motor housing 102 to a junction box 103 connected to the side of the motor housing 102 . Junction box 103 houses various electronic components (eg, bus bars and other electronic disconnects). Wiring, cables, conduit and / or tubing 101 extending from top drive motor housing 102 terminates at a bus bar or other electrical disconnect housed within junction box 103 .

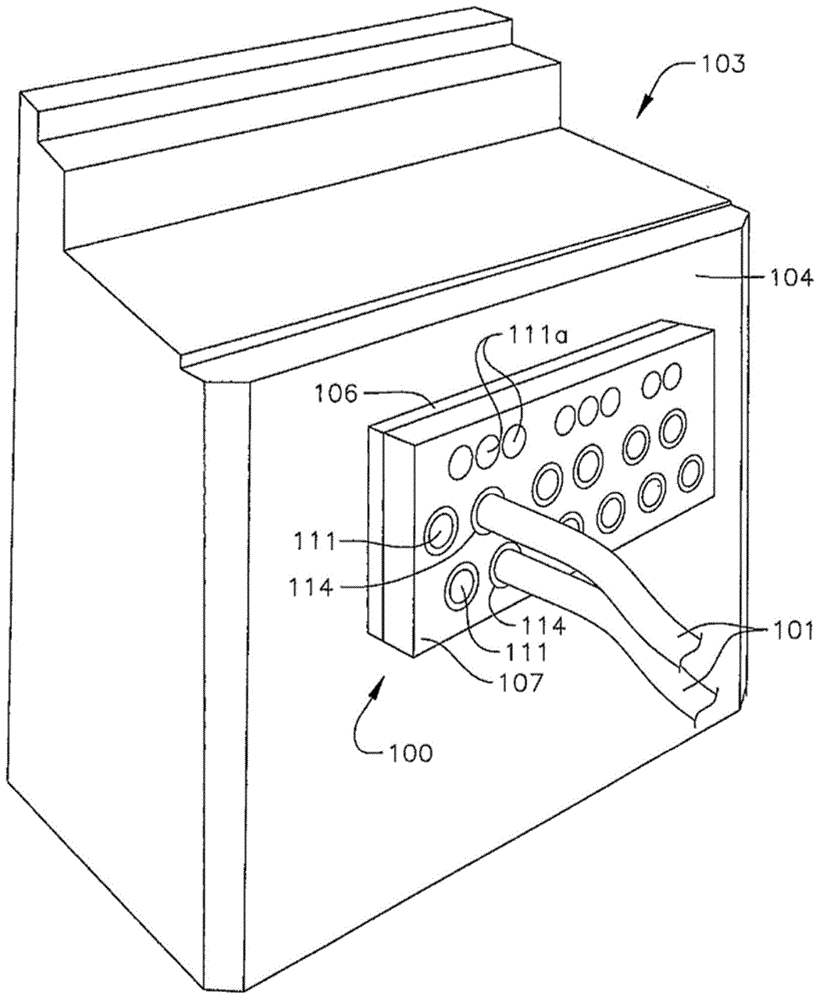

[0016] refer to figure 2 In the illustrated embodiment, the sealing system 100 is attached to the wall 104 of the junc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com