Fast fine grinding and refining manufacturing process for chocolate

A manufacturing process, chocolate technology, applied in cocoa, food science, application, etc., can solve the problems of difficult cleaning, nutrient-rich residual night, difficult cleaning equipment, etc., to shorten production time, smooth taste, change cleaning machinery and equipment the effect of the condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Ingredients 3000g brown chocolate

[0030] 1. Cocoa butter 40%: 1200g 2. Whole milk powder 15%: 450g 3. Cocoa powder 20%: 600g

[0031] 4. White sugar powder 25%: 750g 5. Colloid-microcrystalline cellulose 0.5%: 15g

[0032] 6. Phospholipid 0.3%: 9g

[0033] Heat the cocoa butter in the formula to above 45°C to dissolve, mix whole milk powder, cocoa powder, white sugar powder and colloid-microcrystalline cellulose evenly, disperse in the cocoa butter solution, stir evenly, and grind with a colloid mill For the second time, add phospholipids, evenly, and homogenize once with a high-pressure homogenizer, with a pressure of 750-850kg, to obtain a brown chocolate slurry with a fineness of 4-15 μm, such as figure 1 , after tempering and molding, a smooth, delicious and sweet brown chocolate is obtained.

Embodiment 2

[0035] Ingredients 2000g white chocolate

[0036] 1. Cocoa butter substitute 38%: 760g 2. Coconut oil 5%: 100g 3. Whole milk powder 32%: 640g

[0037] 4. White sugar powder 25%: 500g 5. Colloid-microcrystalline cellulose 0.6%: 12g

[0038] 6. Phospholipid 0.3%: 5g

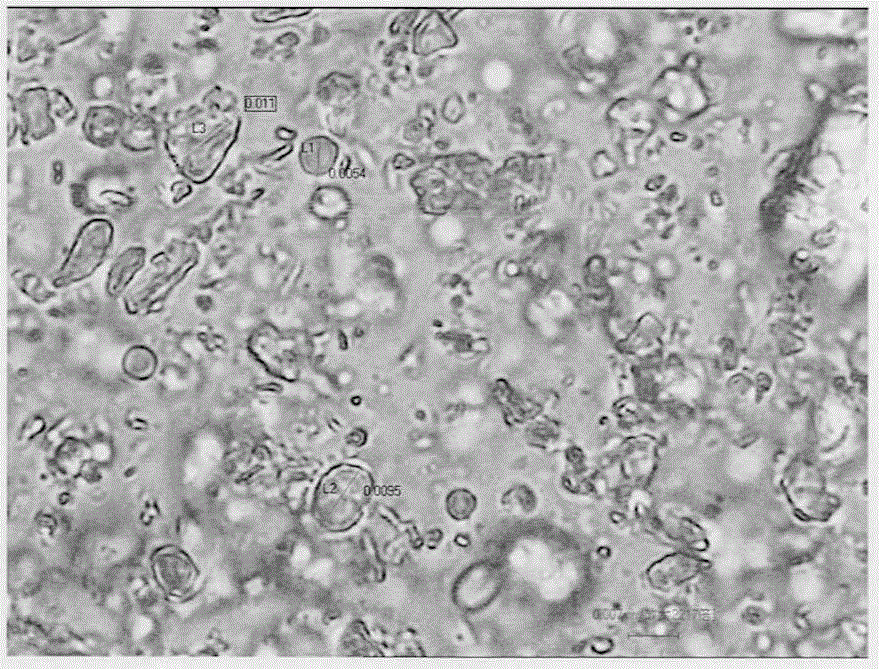

[0039] Heat the cocoa butter substitute and coconut oil in the formula to above 45°C to dissolve and mix, mix the whole milk powder, white sugar powder and colloid-microcrystalline cellulose evenly, disperse in the mixed oil, stir evenly, and use a colloid mill Grind twice, add phospholipids, homogenize twice with a high-pressure homogenizer, the first pressure is 600-700kg, the second pressure is 800-900kg, and the white chocolate slurry with a fineness of about 5-10μm is obtained. Such as figure 2 , after tempering and molding, a fine and smooth milky white chocolate is obtained.

Embodiment 3

[0041] Ingredients 2000g peanut chocolate

[0042] 1. Cocoa butter 17%: 340g 2. Cocoa butter substitute 20%: 400g 3. Pure peanut pulp 27%: 540g

[0043] 4. Whole milk powder 10%: 200g 5. White sugar powder 23%: 460g

[0044] 6. Cocoa powder 3%: 60g 7. Colloid-microcrystalline cellulose 0.6%: 12g 8. Phospholipid 0.2%: 4g

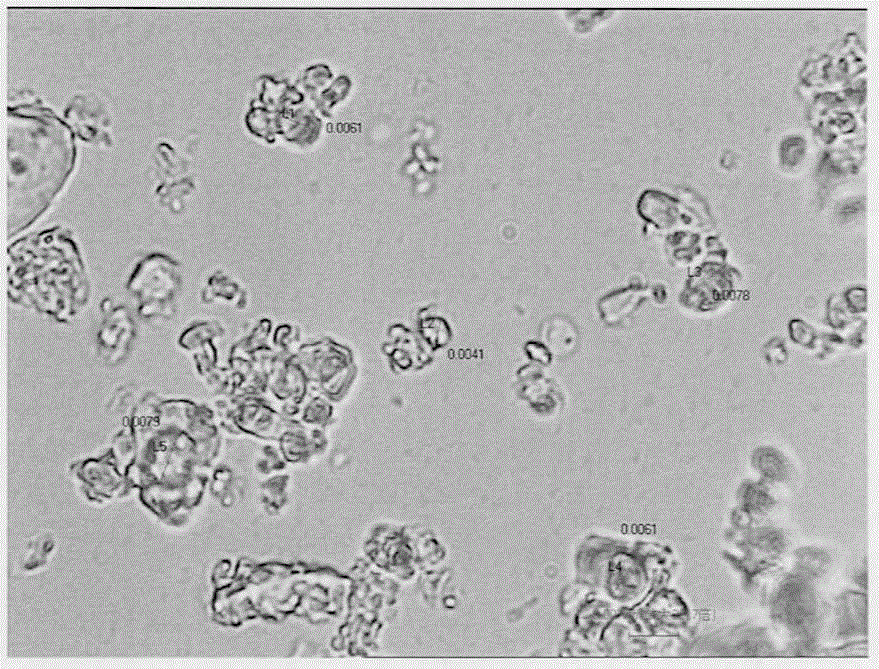

[0045] Heat cocoa butter and cocoa butter substitute in the formula to above 45°C to dissolve, then add pure peanut pulp, stir evenly, mix whole milk powder, cocoa powder, white sugar powder and colloid-microcrystalline cellulose evenly, and disperse in In the mixed oil with peanut pulp, stir evenly, grind twice with a colloid mill, add phospholipids, homogenize three times with a high-pressure homogenizer, the pressure of the first pass is 600-650kg, and the pressure of the second pass is 700-800kg , the third pressure is 900-1000kg, and the fineness is about 4-8μm, and the peanut chocolate slurry with good uniformity is obtained, such as image 3 , after...

PUM

| Property | Measurement | Unit |

|---|---|---|

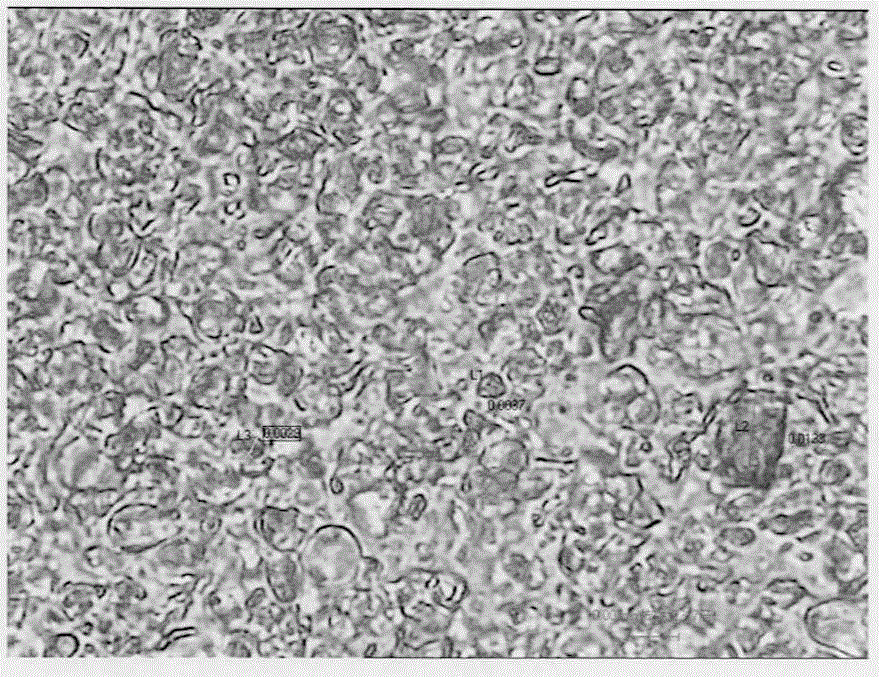

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap