Core assembling tool for casting and core assembling method of casting mould

A casting mold and core assembly technology, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of slow cooling, high mold manufacturing cost, and large amount of sand around the casting, so as to improve the overall quality and reduce the The difficulty of core assembly and the effect of improving the efficiency of core assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

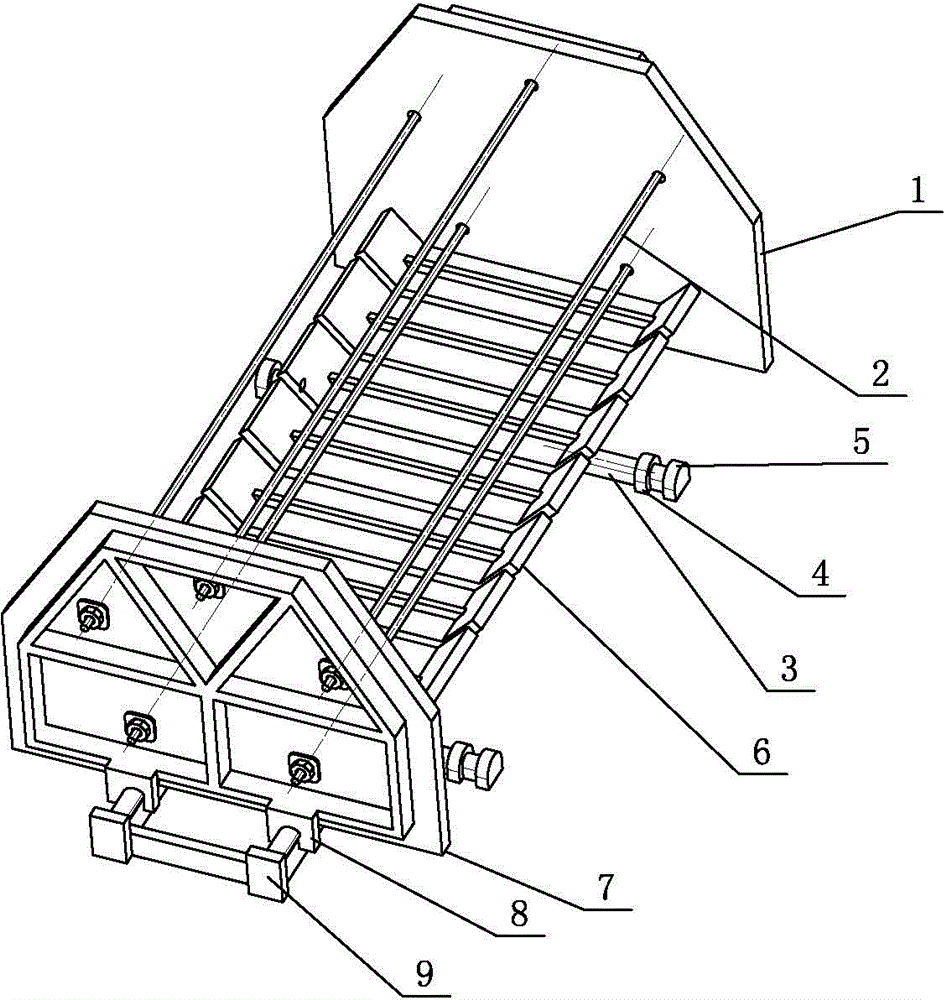

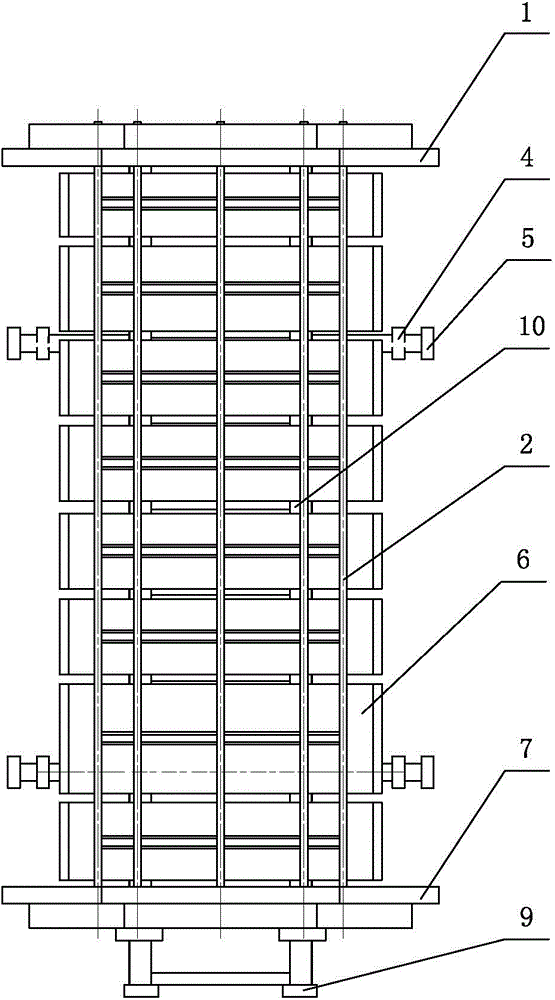

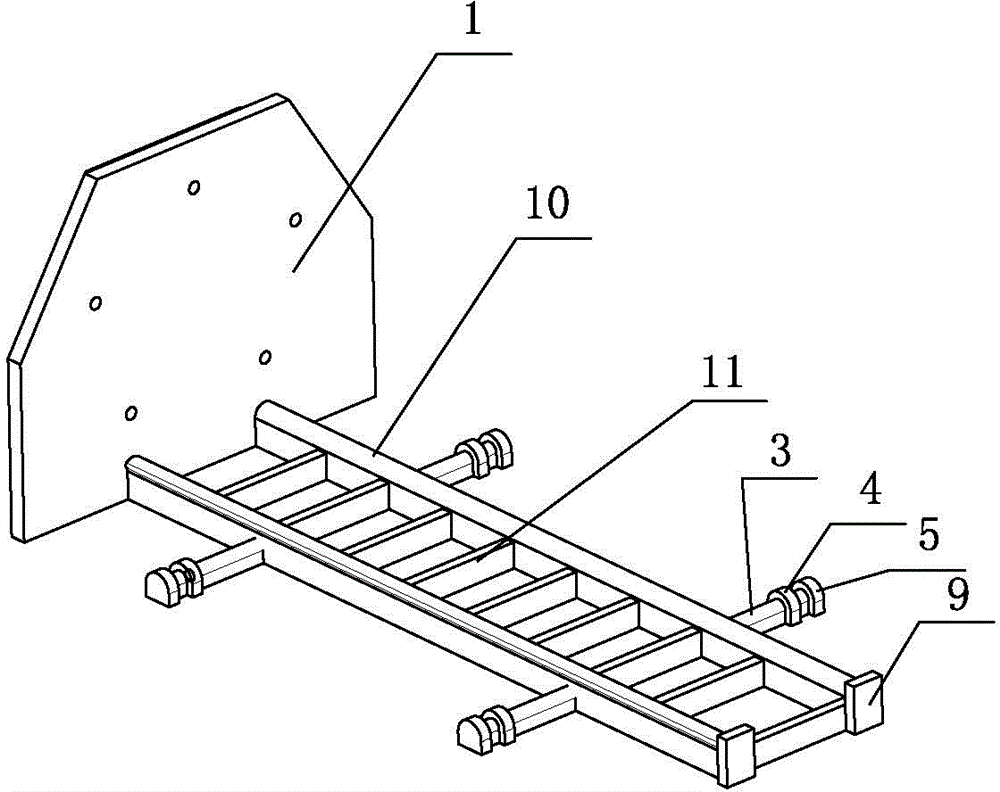

[0022] Such as figure 1 — Figure 4 Shown is the casting core assembly tooling of the present invention, including two rows of guide rails 10 arranged in parallel, a number of reinforcement plates 11 are vertically provided between the guide rails 10, a fixed end plate 1 is vertically provided at one end of the guide rail 10, and a fixed end plate 1 is installed at the other end of the guide rail 10. There are stoppers 9 that protrude from the surface of the guide rail. The distance between the bottom side of the guide rail 10 and the two ends is 1 / 5-1 / 4 of the total length of the guide rail. Hanging shafts 3 perpendicular to the guide rail 10 are respectively provided. The upper side of the guide rail 10 slides with a A number of supporting plates 6 for carrying assembled sub-casting molds. The bottom of the supporting plates 6 is fixed with two rows of slider guide rails 12 inlaid and matched with the guide rails 10. The guide rail 10 near the end of the stopper 9 is also p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com