Automobile engine exhaust manifold parting and parting scheme thereof

A technology for automobile engines and exhaust manifolds, which is applied in the direction of casting molds, cores, and casting mold components. It can solve the problems of difficult control of product size, scrapping of castings, and high trial production costs, and achieve the improvement of process yield and production efficiency. , Improve the effect of manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to illustrate the technical solution of the present invention more clearly, it will be described in detail according to the embodiments of the accompanying drawings. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. For those of ordinary skill in the art, without paying Under the premise of creative work, other drawings can also be obtained based on these drawings.

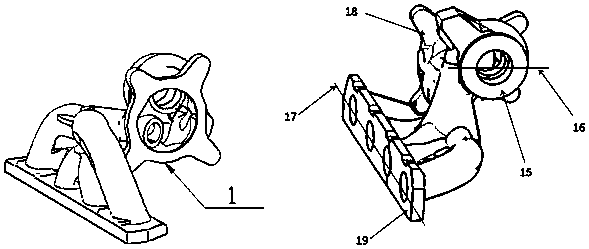

[0029] like figure 1 Shown is a schematic diagram of a three-dimensional model structure of an exhaust manifold for an automobile engine, wherein the exhaust manifold includes four exhaust branch pipes and two total exhaust pipes, and one end of the four exhaust branch pipes is arranged side by side Arranged on the flange surface 19 of the branch pipe, the other end is collected into the main pipe and then discharged through the first general exhaust pipe 15 and the second general exhaust pipe 18, and the central axis of the first gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com