Blank feeding mechanism for bottle blowing machine

A bottle blowing machine and blank feeding technology, which is applied in applications, household appliances, other household appliances, etc., can solve problems such as equipment shutdown, belt jamming, affecting equipment performance, etc., and achieve the effect of reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

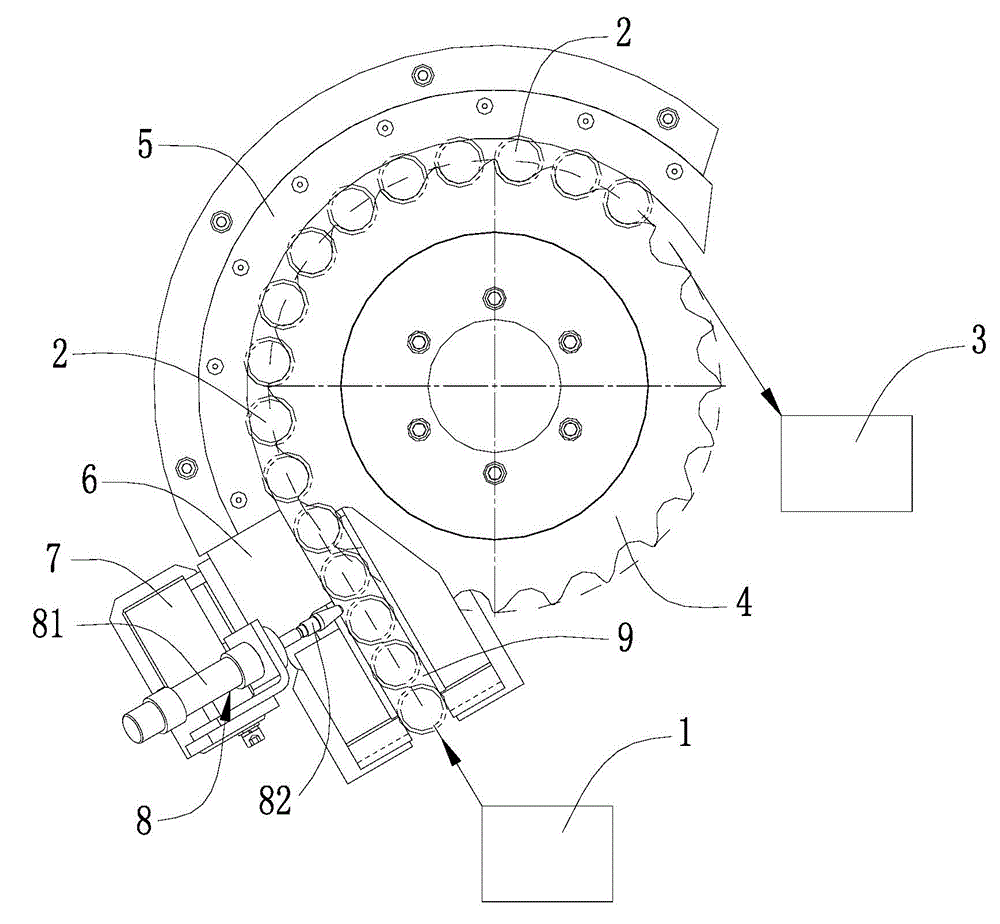

[0016] see figure 1 As shown, the above-mentioned preform feeding mechanism for a bottle blowing machine is arranged on the frame, and the preform feeding mechanism is used to feed the preform 2 that slides off the blank rail 1 into the preform loading mandrel 3 .

[0017] The blank feeding mechanism includes a blank feeding dial 4 arranged on the frame that rotates around its axis, and a ring that is arranged on the outer circumference of the blank feeding dial 4 and is used to cooperate with the blank feeding dial 4 to guide the preform 2 Enter the preform feeding guide plate 5 in the preform loading mandrel 3, the movable guide plate 6 provided at the feeding end of the preform feeding guide plate 5, and the movable guide plate 6 provided on the frame for driving the movable guide plate 6 to slide relative to the preform feeding guid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap