Variable pitch feeding conveying mechanism

A feed conveying mechanism and variable technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of reducing production efficiency, increasing equipment cost and maintenance cost, affecting packaging quality, etc., so as to improve production efficiency and reduce equipment maintenance. Cost, simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

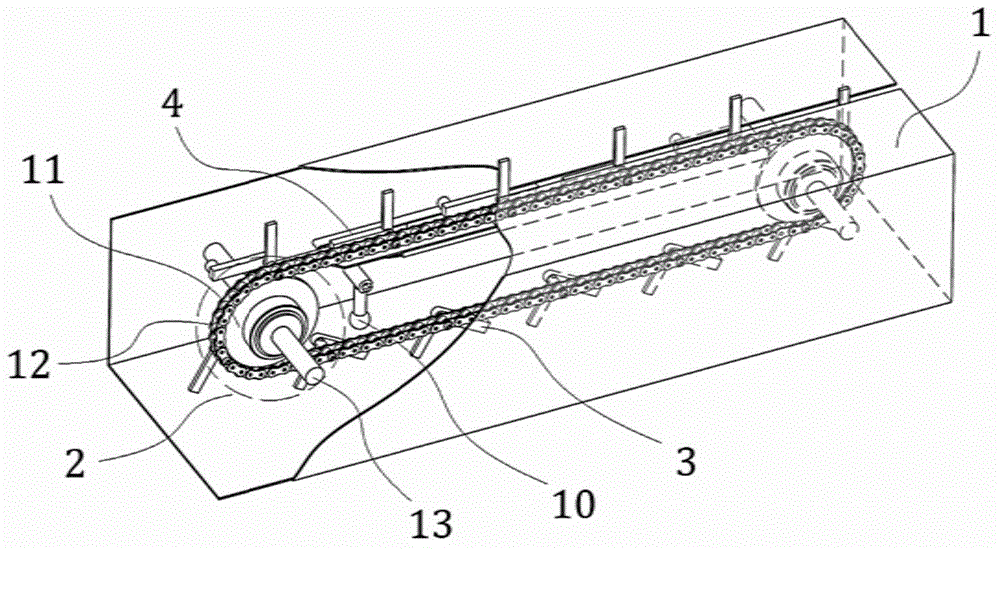

[0022] like figure 1 As shown, this embodiment includes: a frame 1, a chain wheel set 2, a conveying rod 3 and an adjusting device 4, wherein: the sprocket wheel set 2 and the adjusting device 4 are respectively arranged inside the frame 1, and several conveying rods 3 are arranged on the chain The wheel group 2 is driven by the sprocket wheel group 2 to move circularly, and the conveying rod 3 is in contact with the adjusting device 4 .

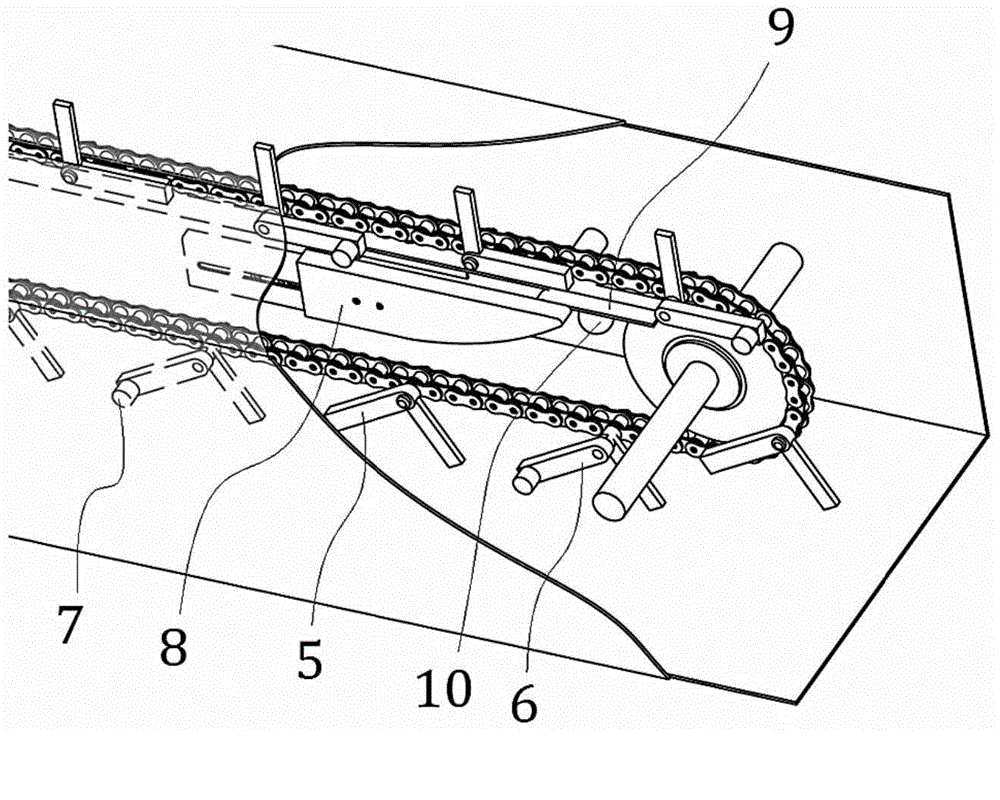

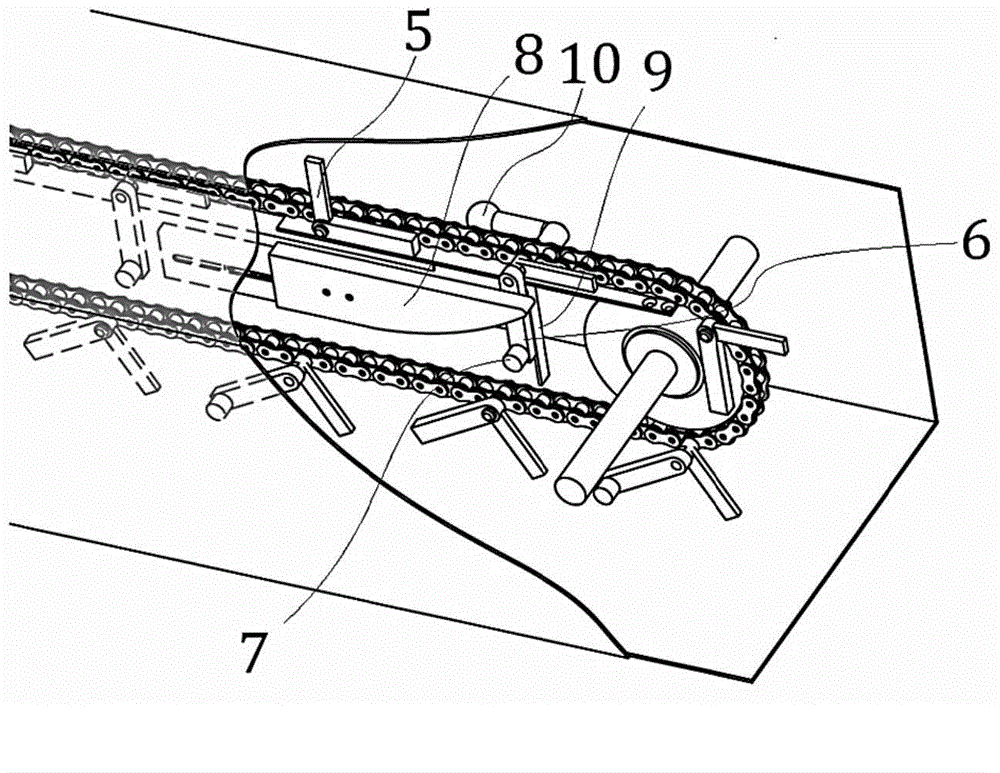

[0023] like figure 2 and image 3 As shown, the conveying rod 3 is an L-shaped structure, including: a fixed push rod 5 and a variable push rod 6, wherein: the middle parts of the fixed push rod 5 and the variable push rod 6 are arranged on the chain through a pin rotation Wheel set 2 on. Both the bottom of the fixed push rod 5 and the variable push rod 6 are in contact with the upper surface of the chain bearing plate 14 to keep the balance of the push rod.

[0024] The end of the variable push rod 6 is provided with a contact block 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com