Roller member, sheet feeder and image forming apparatus

一种输送装置、辊部件的技术,应用在片材输送装置以及图像形成装置领域,能够解决片材偏移、更换需要时间、成本上升等问题,达到简单结构的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Hereinafter, a roller member, a sheet conveying device, and an image forming apparatus according to embodiments of the present invention will be specifically described based on the drawings. In addition, the roller member, the sheet conveyance device, and the image forming apparatus of the present invention are not limited to those shown in the following embodiments, and can be appropriately changed and implemented within a range that does not change the gist.

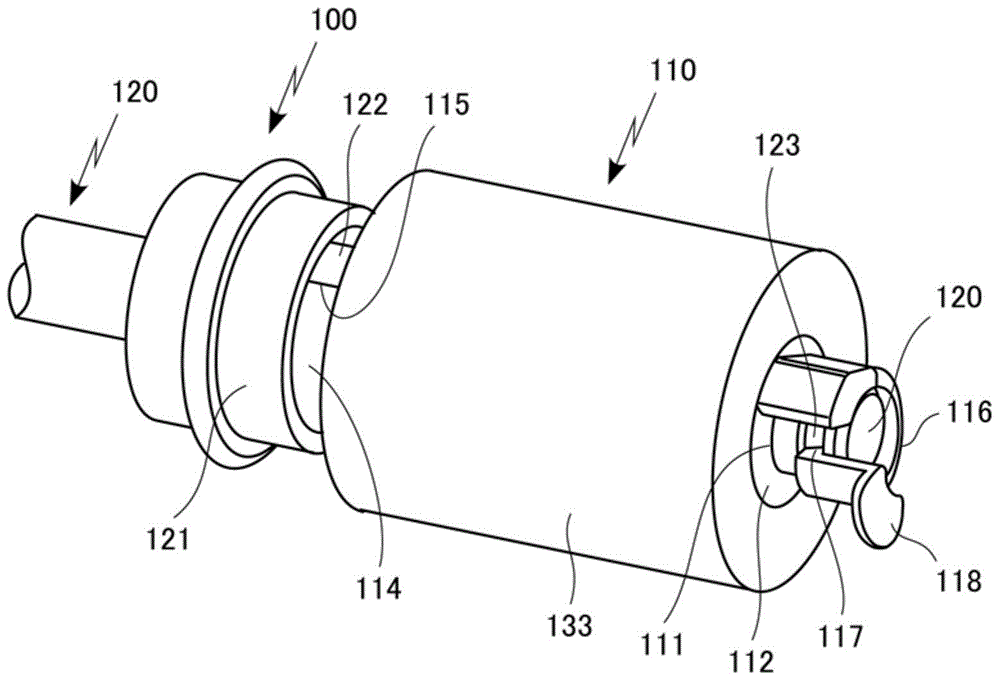

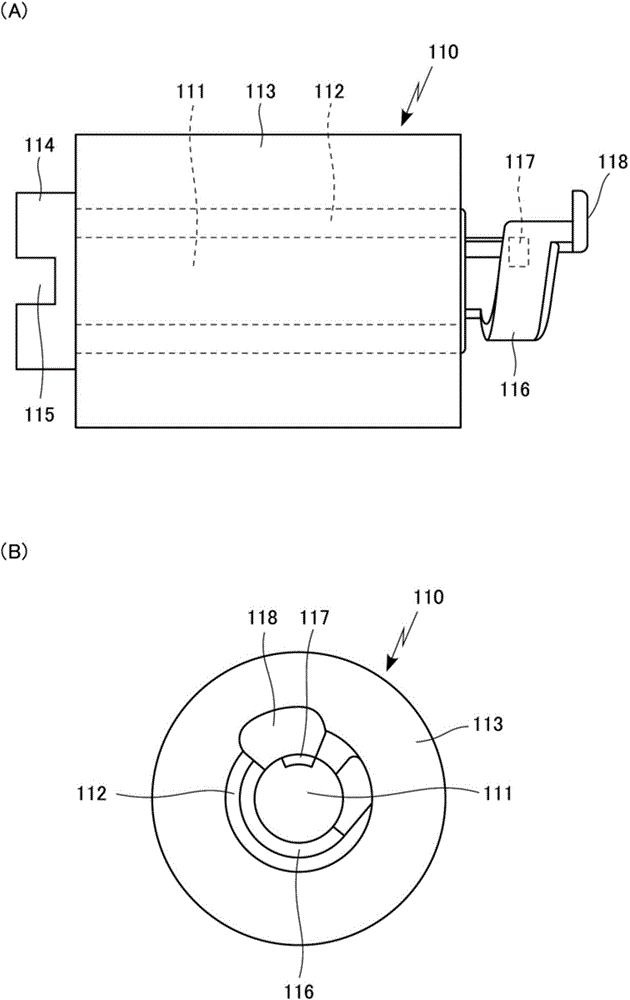

[0063] In the roller member 100 of this embodiment, as figure 1 As shown, the rotation shaft 120 is inserted through the through hole 111 of the roller portion 110 , and the roller portion 110 is detachably attached to the outer periphery of one end side of the rotation shaft 120 .

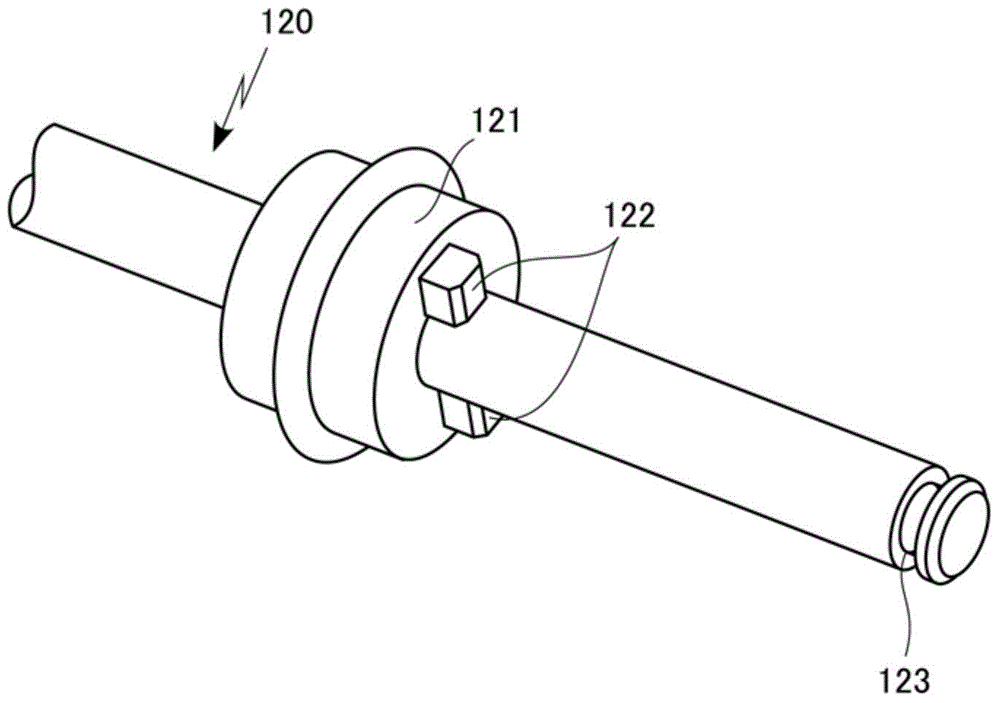

[0064] Here, in the rotating shaft 120, as figure 2 As shown, when the rotating shaft 120 is inserted through the through hole 111 of the roller part 110, the positioning holding part 121 for positioning and holding the one end si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com