Adjustable formwork for floor construction and its construction method

A technology for adjusting templates and templates, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc. It can solve the problems that cannot meet the precision requirements of floor construction, and achieve the reduction of procurement and production costs and the accuracy Improvement and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

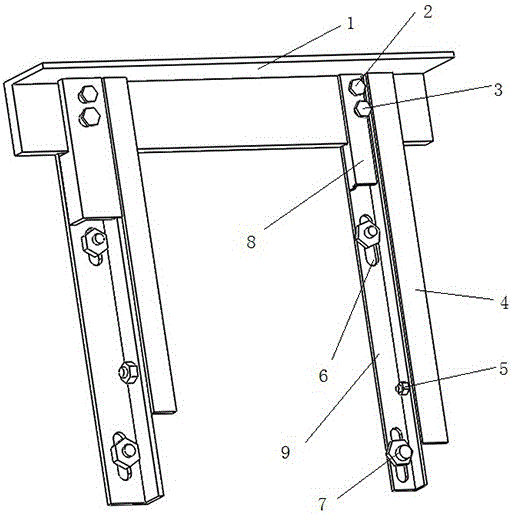

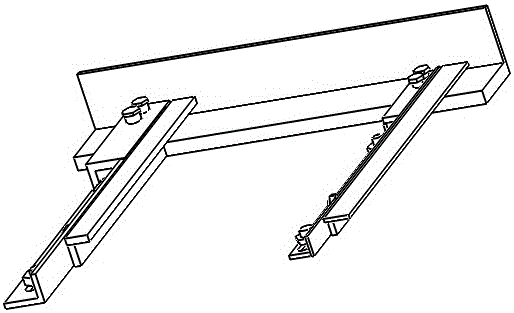

[0034] Such as figure 1 , figure 2 As shown, the adjustable formwork for floor construction includes a formwork angle steel main body 1, and one side of the formwork angle steel main body is a lifting device. The fixed base 9 on the angle steel main body is provided with at least two adjustable elongated holes 6, and the fixed base is connected to the formwork angle steel main body through a connecting block 8, and the connecting block is provided with adjustment bolts and compression bolt holes . The formwork attachment rod 4 is connected to the fixed base 9 through hinge bolts 5 , and the fixed base 9 of the lifting device is fixed on the foundation through expansion bolts 7 . The distance between the fixed base on one side of the main body of the formwork angle steel and the distance between the formwork attachment rods can be set as required.

[0035] The construction method of the adjustable formwork for floor construction, the steps of using the method are as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com