Replacing press gas oil extraction device and method

A technology of oil recovery device and gas source, which is applied in the field of replacing compressed gas oil recovery device, can solve the problems of poor oil recovery effect and large power, and achieve the effects of saving external gas source, high work efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structure of the present invention will be explained in detail below in conjunction with the accompanying drawings.

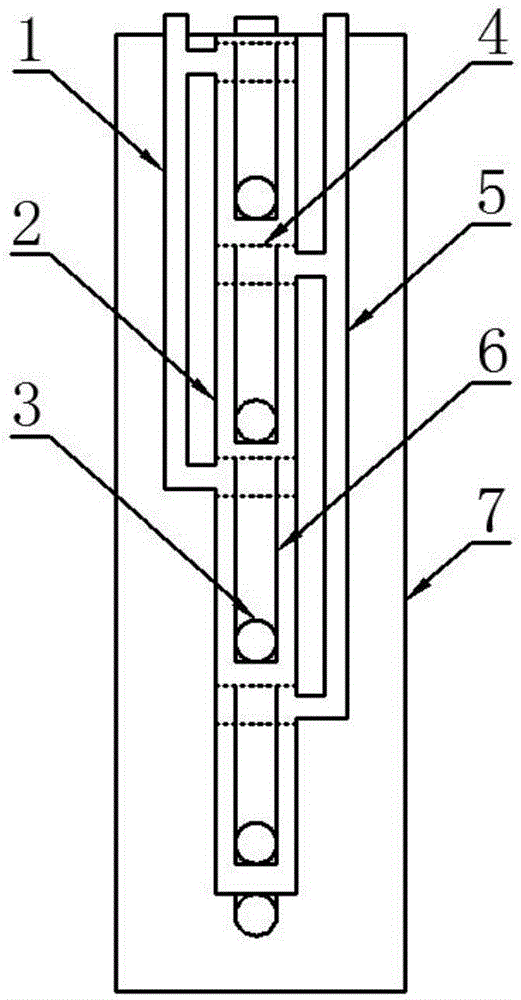

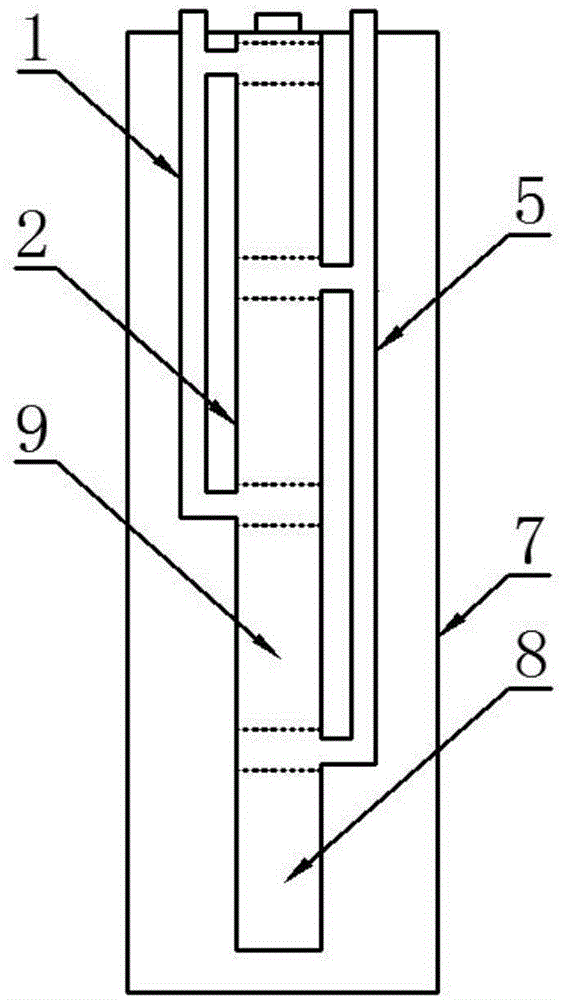

[0026] Such as figure 1 The structural diagram of the replacement compressed gas oil production device shown is a replacement compressed gas oil production device, which includes a casing 7, and the casing 7 is provided with an outer oil pipe 2, a gas source pipe A1 and a gas source pipe B5, and the outer oil pipe 2 is equidistantly spaced. Several sealing discs 4 are installed, and the sealing discs 4 divide the outer oil pipe 2 into several cavities, such as figure 2 As shown, from bottom to top, the 1st, 3rd, 5th... chambers are odd chambers 8, the 2nd, 4th, 6th... chambers are even chambers 9, and the upper part of each chamber corresponds to the odd / even numbered ones Seal the pan4.

[0027] The sealing disc 4 of the present invention has three functions: 1. divide the outer oil pipe 2 into odd chambers 8 and even chambers 9 spaced apart from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com