Lifting and detecting device for building thin-wall pipelines and lifting method

A thin-walled pipeline and detection device technology, applied in the directions of measuring devices, transportation and packaging, load hanging components, etc., can solve the problems of deformation of thin-walled pipelines in buildings, complicated installation process, affecting installation quality, etc., to speed up construction progress, The effect of improving the smoothness of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

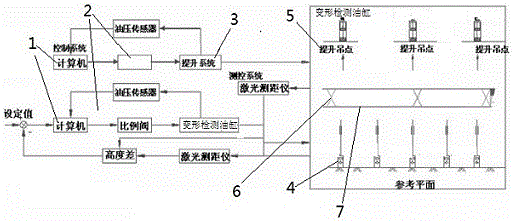

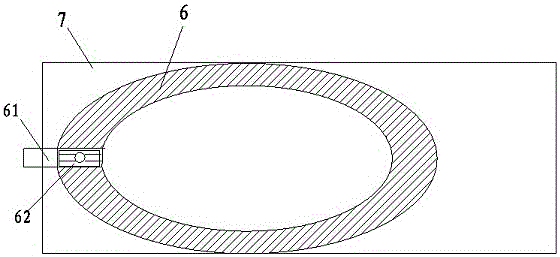

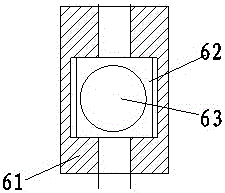

[0020] Such as figure 1 As shown, the present invention is a hoisting detection device for building thin-walled pipelines, the device includes a control system 1, a hydraulic system 2, a lifting system 3, and a distance measuring system 4; the control system 1 uses a computer to control the output power of the lifting system 3 ; The lifting system 3 is fixedly installed below the lifting point 5 of the thin-walled pipeline of the building through several deformation detection oil cylinders; an oil pressure sensor is installed on the deformation detection oil cylinder of the lifting system 3, and the oil pressure sensor and the control The system 1 is connected by wires; a laser range finder is installed under each lifting point 5; the laser range finder is connected to the control system 1 through a signal line, and the control system 1 adjusts the height of each lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com