A fully plastic core rotatable and telescopic faucet

A faucet and valve core technology, applied in the field of kitchen and bathroom utensils, can solve the problems of inability to take into account the height and rotation, simultaneous adjustment, human health hazards, etc., and achieve the effects of reducing the probability of breeding bacteria, avoiding hazards, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

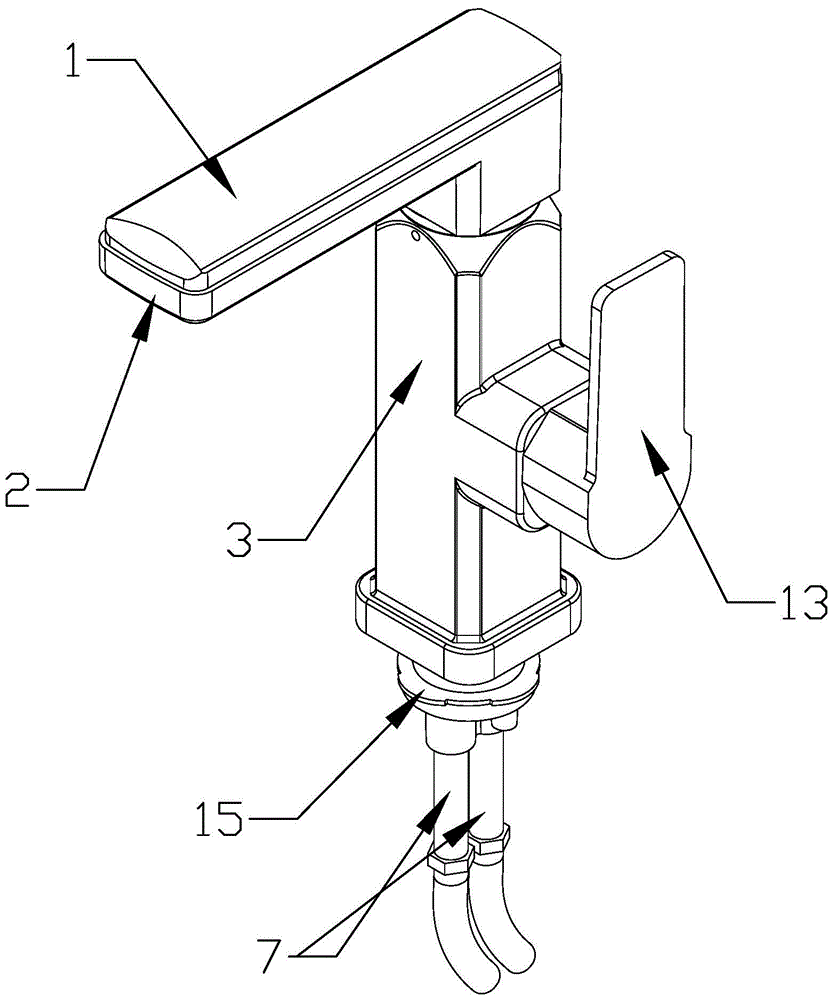

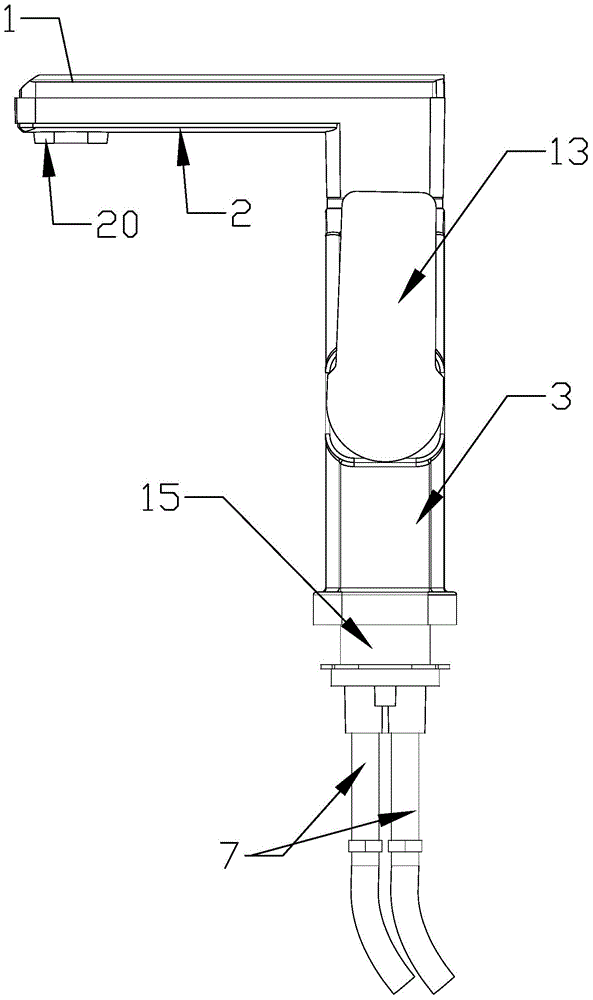

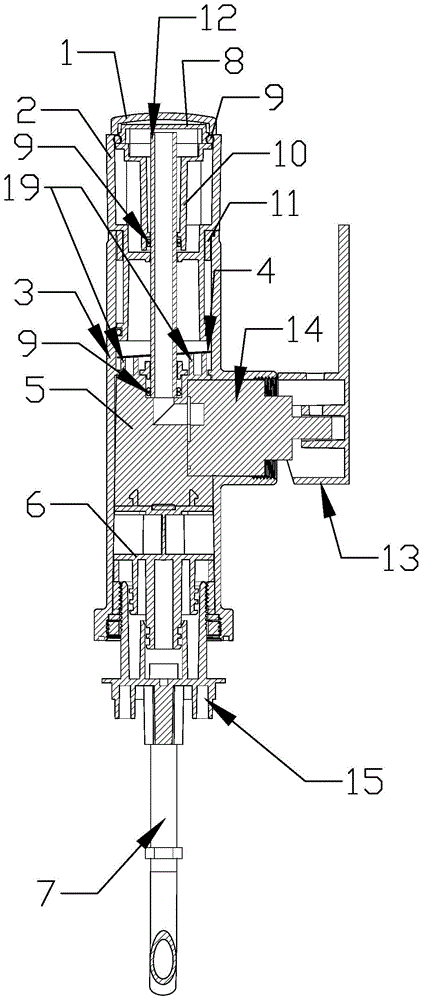

[0027] Such as Figure 1-Figure 9 As shown, the all-plastic core rotatable and retractable faucet of this embodiment includes a valve seat 5, a water inlet mechanism connected to the bottom of the valve seat 5, and a valve core 14 arranged in the valve seat 5 to control the tap switch. A water outlet pipe 12 is provided above the valve seat 5, and an inner rotor core 10 that can slide up and down and rotate along the outlet pipe 12 is sleeved on the outlet pipe 12, and an inner rotor core 10 is connected to the inner rotor core 10 Shell 8, the end of the inner rotor core 10 is provided with a water outlet 20, the water inlet mechanism, the valve seat 5, the valve core 14, the water outlet pipe 12, the channel formed by the inner rotor core 10 and the inner core upper shell 8, The water outlet 20 is in communication, and a handle 13 for driving the rotation of the valve core 14 is fixed on the outer wall of the valve core 14; the inner core upper shell 8 and the inner rotor core...

Embodiment 2

[0036] Such as Picture 10 As shown, in the fully plastic core rotatable and retractable faucet of this embodiment, the water inlet mechanism is a water inlet pipe 7, and the water inlet pipe 7 is in communication with the valve seat 5. The other structure and usage are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com