No-clean soldering flux for low-silver solder to weld brass

A technology of silver solder and flux, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problem that the flux cannot achieve the welding effect, etc., to avoid corrosion, reduce production costs, and reduce environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

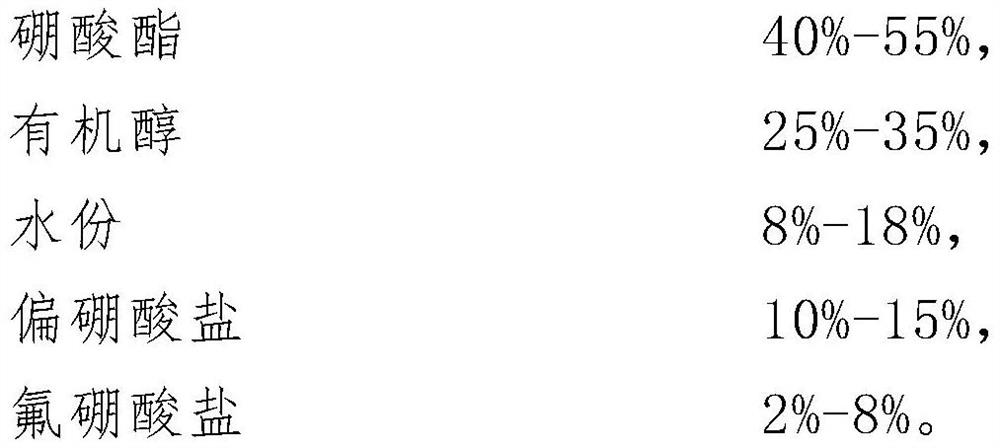

[0021] The present embodiment provides a flux for soldering brass with a silver content of 1 wt %, and the components of the flux by weight are:

[0022]

[0023] The flux is a fluid with water and organic alcohol as dual solvents.

[0024] When the above-mentioned flux is used to solder the brass to the brass, the above-mentioned flux is applied to the surface of the solder, and the brass is soldered with the flux-coated solder at 750°C. At 750°C, trimethyl borate in the flux burns to generate diboron trioxide gas, which reacts with oxides on the brass surface to form borate, and the brass with the oxide surface removed is clean of brass. Metaborate and fluoroborate enter into the molten solder to promote the flow of the solder, so that the solder flows evenly on the clean brass surface, completing the welding of brass parts. At the same time, the excess boron trioxide gas is completely volatilized, and there is no residual inorganic salt at the weld after welding, and n...

Embodiment 2

[0026] The present embodiment provides a flux for soldering brass with a silver content of 3wt%, and the flux composition is:

[0027]

[0028] The flux is a fluid with water and organic alcohol as dual solvents.

[0029] The application process of this embodiment is the same as that of Embodiment 1, and the only difference is that the welding temperature is different, which is 700°C. At the same time, due to the change of the composition ratio of the flux, the coating amount is adjusted accordingly according to the actual welding temperature and other parameters.

Embodiment 3

[0031] This embodiment provides a flux for soldering brass with a silver content of 5wt%, and the flux composition is:

[0032]

[0033] The flux is a fluid with water and organic alcohol as dual solvents.

[0034] The application process of this embodiment is the same as that of Embodiment 1, and the only difference is that the welding temperature is different, which is 600°C. At the same time, due to the change of the composition ratio of the flux, the coating amount is adjusted accordingly according to the actual welding temperature and other parameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com