Bow and arrow structure and its bow arm fixing component

A technology for fixing components and bow arms, which is applied in the field of bow and arrow structures, can solve the problems of complicated assembly process and high manufacturing cost, and achieve the effects of simple assembly, low manufacturing cost, and reduced noise or vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

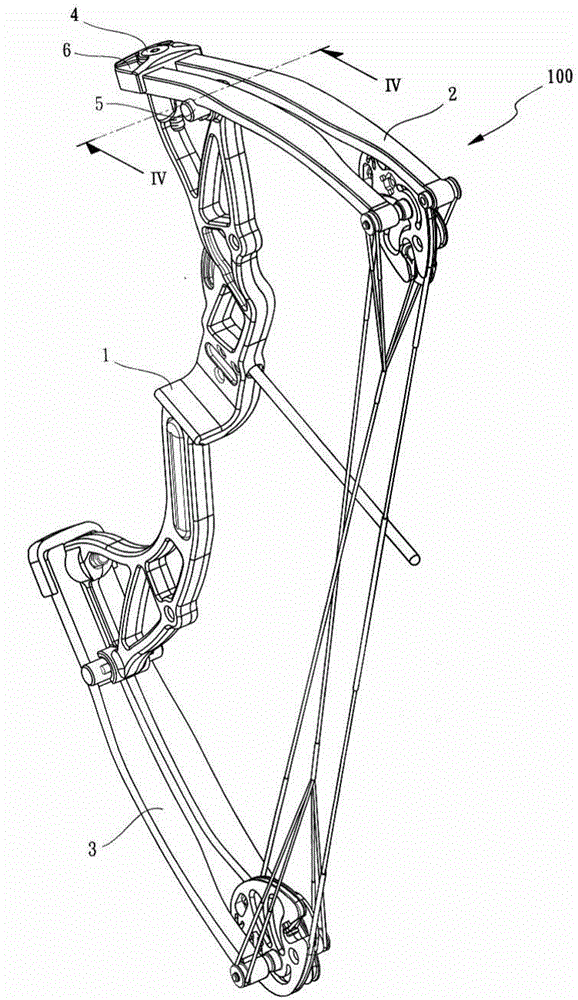

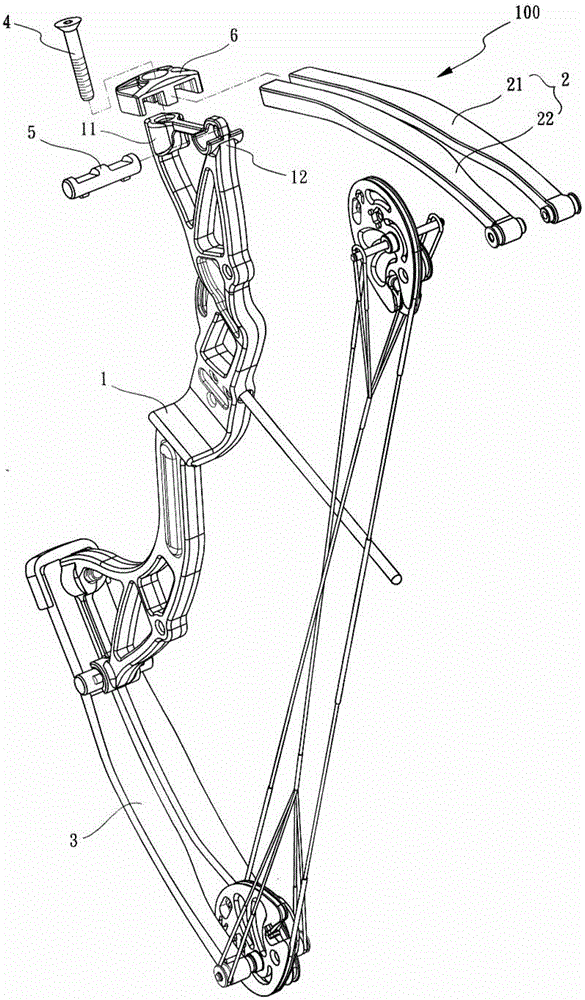

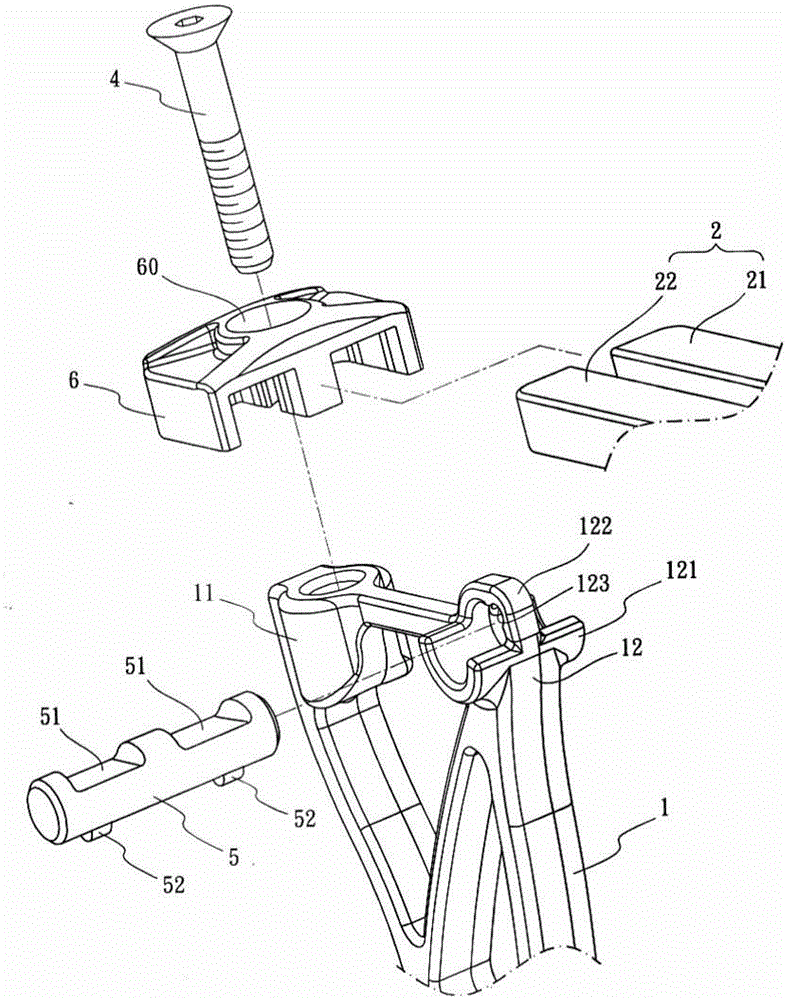

[0056] refer to Figure 1 to Figure 6, which is a schematic diagram of a preferred embodiment of the bow and arrow structure 100 of the present invention. First, if figure 1 and figure 2 As shown, the bow and arrow structure 100 mainly includes a metal bow handle 1 , two bow arms 2 , 3 , and two bow arm fixing components for fixing the two bow arms 2 , 3 to both ends of the bow handle 1 . Each bow arm fixing assembly includes a bolt 4 , a limiting shaft 5 and a bow arm cover 6 . Since the two bow arms 2 and 3 are vertically symmetrical, the preferred embodiment of the present invention will be briefly described below only for one of the bow arms 2 and its corresponding bow arm fixing assembly.

[0057] Such as image 3 As shown in the enlarged view of , the front edge of the top end of the bow grip 1 forms a fixing portion 11 , while the rear edge forms a support portion 12 . The supporting portion 12 includes an arc bracket 121 and an arch bracket 122 . As shown in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com