Manufacturing Process for Graphite Heat Sinks

A technology of graphite heat sink and manufacturing process, which is applied in the direction of cooling/ventilation/heating transformation, modification through conduction heat transfer, pressing roller, etc., which can solve problems such as uneven heat dissipation, overheating of tape, poor reliability performance, etc., and achieve improvement Flatness and flexibility, improved bidirectional tensile properties, overcoming the effect of excessive heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Embodiment: a kind of manufacturing process that is used for graphite heat sink, described graphite heat sink obtains through the following steps:

[0041] Step 1, coating the graphite modifier respectively on the upper and lower surfaces of the polyimide film to obtain the treated polyimide film, the treated polyimide film is composed of the polyimide film, the first coating layer and the second coating layer composition;

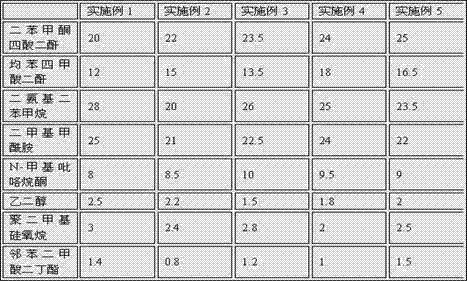

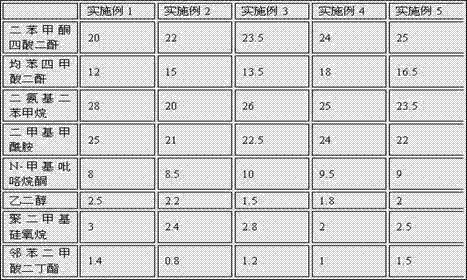

[0042] Described graphite modifier is made up of the component of following parts by weight:

[0043] Table 1

[0044]

[0045] Step 2. Under the protection of an inert gas, the treated polyimide film is raised from room temperature to 240°C~260°C, after heat preservation, it is raised to 480°C~500°C, and after heat preservation, the temperature is raised to 780°C~820°C. After heat preservation, it is raised to 1200°C and then cooled to obtain a pre-fired carbonized film;

[0046] Step 3: heating the carbonized film to 2350°C~2450°C, keeping i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com